25 / 49Festo 7DSBGa_en

4.3.7 Repairing and attaching the bearing and end caps

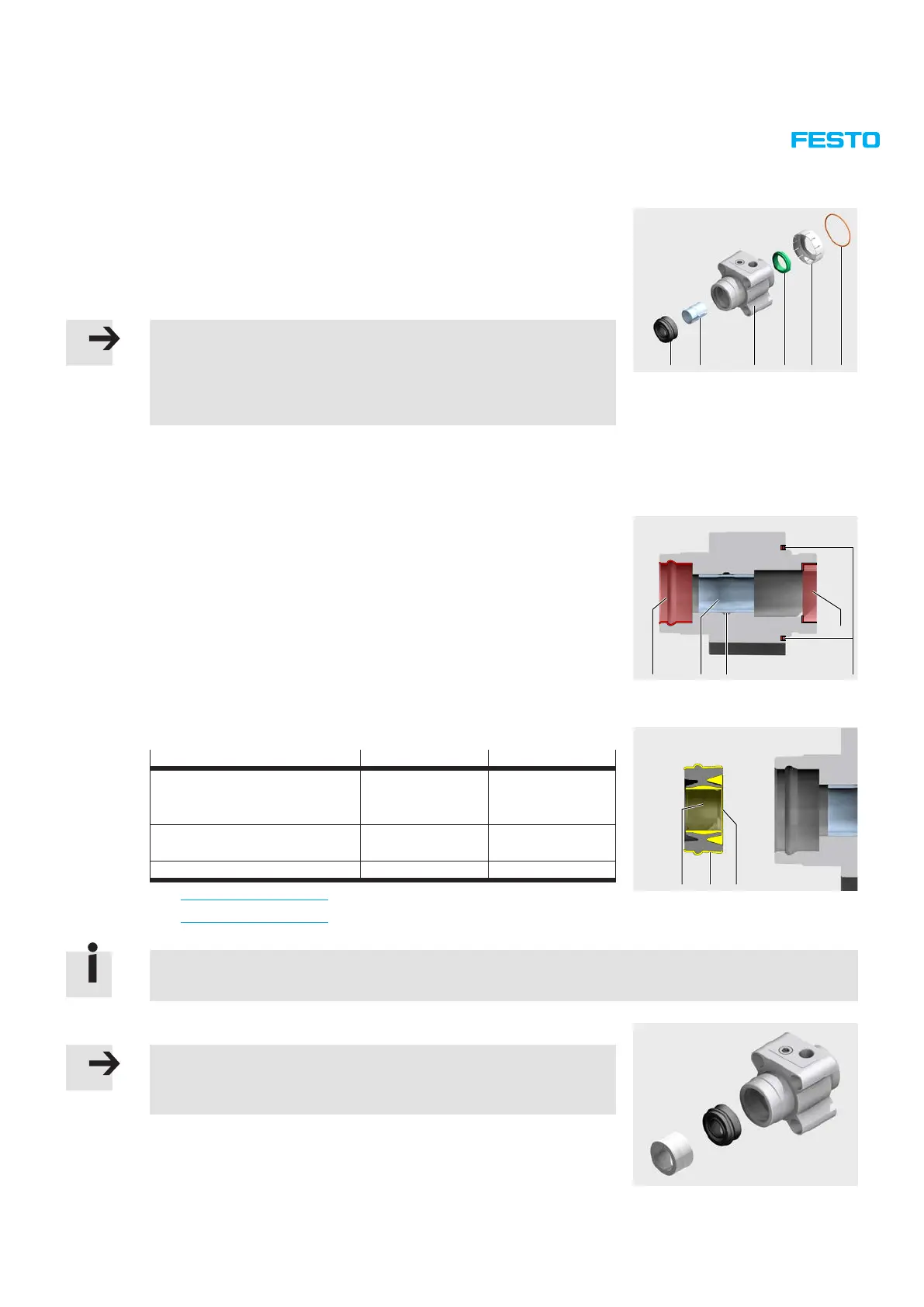

1. Remove the scraper ring 1 from the bearing cap 3.

2. Remove O-ring 6 from the bearing cap and the end cap.

3. Pull the holding discs 5 off the bearing cap and end cap.

4. Remove the buffer seal 4 from the bearing cap and end cap.

5. Check the bearing 2 in the bearing cap.

Note

ISO standard cylinder with metal bearing (DSBG-...-Q / L / U / EX4)

In case of identiable damage to the bearing, which could impair its function

(e.g. deposits or scoring), the bearing cap or the bearing cap with end posi-

tion locking must be completely replaced.

6. ISO standard cylinder with plastic bearing:

If the bearing is damaged, press together at the inner end to unlock and

push out of the bearing cap.

1 2 3 4 5 6

7. Clean the seat of the scraper ring 1.

8. Clean the seat of the buffer seal 4.

9. Clean the seat of the O-ring 5.

10. ISO standard cylinder with plastic bearing:

Insert new bearing into the bearing cap. Push the bearing until the middle

shoulder of the bearing latches into the slot 3 in the bearing cap.

11. Grease the sliding surfaces of the bearing 2 with a thin lm of the grease

included in the set of wearing parts.

Fill the grease reservoir in the bearing 2/3 full with grease included in the

set of wearing parts.

2 53

4

1

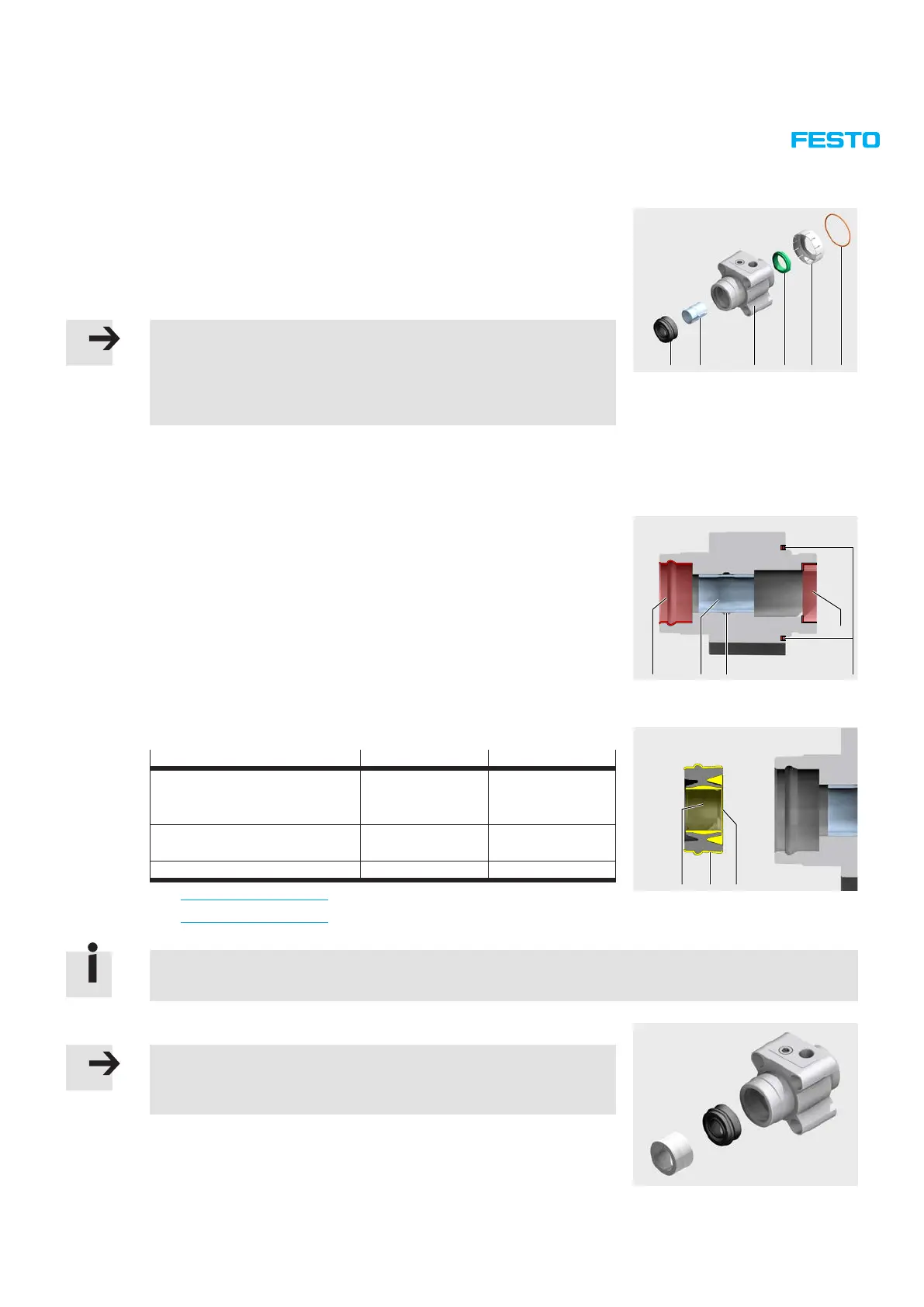

12. Grease the new scraper ring as follows:

Area Cylinder with L / U Other cylinders

1 Surface facing piston rod Apply a thin

1)

lm

of grease on the

surface

Fill grease reser-

voir 2/3 full with

grease

2)

2 External surface for bearing

cap

apply a thin lm

1)

of grease

apply a thin lm

1)

of grease

3 Grease reservoir

2)

for bearing Fill 1/3 with grease Fill 2/3 with grease

1)

Chapter 5.2.1 on page 47

2)

Chapter 5.2.2 on page 47

1 2 3

To mount the scraper ring, note the version of the ISO standard cylinder:

DSBG-...- (standard version) or DSBG-...-A3 (suitable for unlubricated operation)

DSBG-...- (standard version)

Note

Note the mounting direction of the scraper ring:

Individual sealing lip or labelling facing the outside.

13. Use a suitable thrust piece to insert the scraper ring into the bearing cap.

Loading...

Loading...