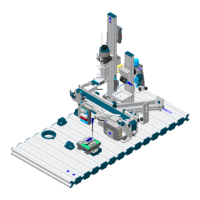

Point-to-point operation

Sequence

The diagrams show the movements in point-to-point operation

– Mov

Out

: position-controlled movement to the end position "Lim

Out

"

– Mov

In

: position-controlled movement to the end position "Lim

In

"

– Mov

Imp

: position-controlled movement to the intermediate position "Pos

Imp

"

– Point-to-point operation with press function, from Start Press Position "Pos

Start Press

"

– Mov

Out

: force-controlled movement until the parameterised force or torque setpoint

value "Force" is reached or to the end position "Lim

Out

"

– Mov

Imp

: force-controlled movement to the intermediate position "Pos

Imp

" (IO-Link only)

Simple point-to-point operation

Simple point-to-point operation with intermediate position (IO-Link only)

Point-to-point operation with press function

Point-to-point operation with press function and intermediate position (IO-Link only)

1) 10, 20, ..., 100% of maximum value

2) Only required for point-to-point operation with press function

3) Reset at every referencing

4) Reference point: reference end position "Ref"

5) The output stage remains active, the drive decelerates to standstill and remains stationary position-con-

trolled.

6) In error-free status the output stage is switched off after 3 s, the drive coasts to a standstill and remains

stationary unregulated.

Tab. 6: Parameterise and control point-to-point operation

10 Malfunctions

Acknowledge error

With error acknowledgment, active error messages are deleted from the diag-

nostic memory if the cause of the error was remedied before acknowledgment.

Errors can be acknowledged via the following interfaces:

–

Restart:

–

Logic voltage L

+

, Power OFF/ON [Logic, Pin 1]

– HMI:

– Press and hold for 3 s

– DIO, digital inputs:

– DI1 "Mov

In

" and DI2 "Mov

Out

" = 1 [Logic, Pin 5/6]

–

IO-Link, device data:

–

0x0107.0 Quit Error = true

– IO-Link, process data:

– 0x0029.3 Quit Error = true

–

0x0029.1 and 0x0029.2 = true, 0x0029.5 = any

Diagnostic messages and fault clearance

"Information, Warnings and Errors" diagnostic messages are displayed by the

C/Q LED and menu and parameters LED displays.

Errors are reported to the controller as follows:

–

DIO operation: output signals DO1 and DO2 = 1 [Logic, Pin 2/3]

– IO-Link operation: ProcessDataInput state "In" (0x0028.1) and state "Out"

(0x0028.2) = true

The first error that occurred is always displayed.

Fig. 8: Display of diagnostic messages (example)

Error

code

Description LED LED displays Event

code

hex

(dec)

C/Q Menu Parameter (IO-

Link)

Warning

z Warnings

1)

yellow

light

z 0x...

Error

z Common device error or

unlisted errors

red light

…

0x1000

Remedy

– Contact Festo

0x000F

(15)

I

2

t monitoring output stage

error limit

0x1805

Remedy

–

0x0016

(22)

Undervoltage in logic supply

24V

2)

0x1804

Remedy

– Check logic voltage supply

0x0017

(23)

Overvoltage in logic supply

24V

0x1803

Remedy

– Check logic voltage supply

0x001F

(31)

Undervoltage in DC link 0x1806

Remedy

– Check the load voltage

supply

0x0026

(38)

Undervoltage in load supply

24V

0x1802

Remedy

– Check the load voltage

supply

0x0027

(39)

Overvoltage load supply 24 V 0x1801

Remedy

– Check the load voltage

supply

0x0031

(49)

Device undertemperature 0x4000

Remedy

– Check ambient conditions

0x0033

(51)

Device overtemperature

Remedy

– Check ambient conditions

– Check installation condi-

tions

Loading...

Loading...