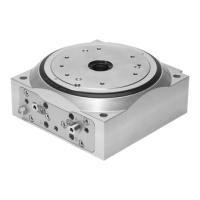

What to do if the Festo DHTG-140-4-A Industrial Equipment rotating plate does not move?

- SsamanthamedinaJul 25, 2025

If the rotating plate on your Festo Industrial Equipment doesn't move, it could be due to several reasons. First, check if the overload protection is active. You can resolve this by pressurizing connection (B) and turning the plate back against the direction of rotation as far as possible to engage the overload protection. Another cause may be that the flow-control screw is closed completely; if so, open the screw. If you hear an audible leakage, send the DHTG to Festo.