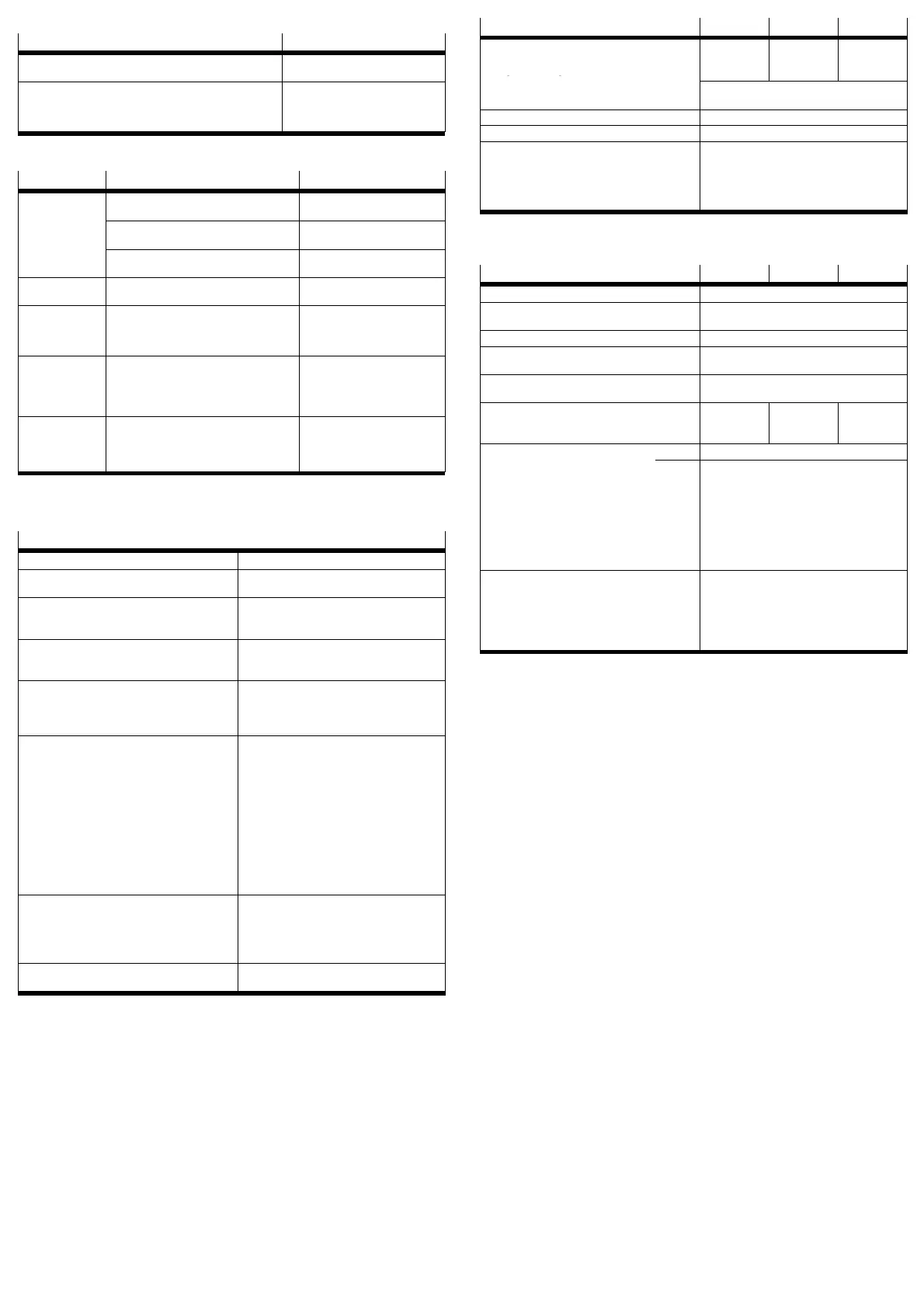

12 Eliminating malfunctions

Cause Error display

Limit value not reached (setpoint value)

Limit value exceeded (setpoint value)

ER.09

ER.10

Undervoltage in the 24 V operating voltage

Overvoltage in the 24 V operating voltage

Hardware error

Temperature range exceeded in VPPM−...C1

ER.05

ER.26

ER.01

ER.28

Fig.35

Malfunction

Possible cause Remedy

VPPM−..C1 notre

acting

Supply voltage not applied, POWER LED

does not light up

· Check connection of the

24 V DC power supply

Set value voltage or set value current not

applied

· Check controller

· Check connection

VPPM−... C1 defective Send the device to Festo for re

pairs.

Flow rate too low Restriction of the flow cross section due to

connection design (swivel fittings).

· Use an alternative connec

tion

Pressure in

creasetoo slow

Large cylinder volume and long tubing · Select different parameter

set

· Use larger nominal size

VPPM−...C1

Pressure constant

despite modified

setpoint specifi

cation

Supply cable breakage (the last output

pressure set is maintained but not regu

lated. In the medium term the pressure

at the output can increase or diminish).

Supply pressure P1 too low

· Replace power supply cable

· Increase supply pressure

UP/DOWN

buttons on the

VPPM−...C1 do not

react.

Voltage is present at digital inputs D1 and

D2.

· Apply 0 V DC to digital in

puts D1 and D2.

Fig.36

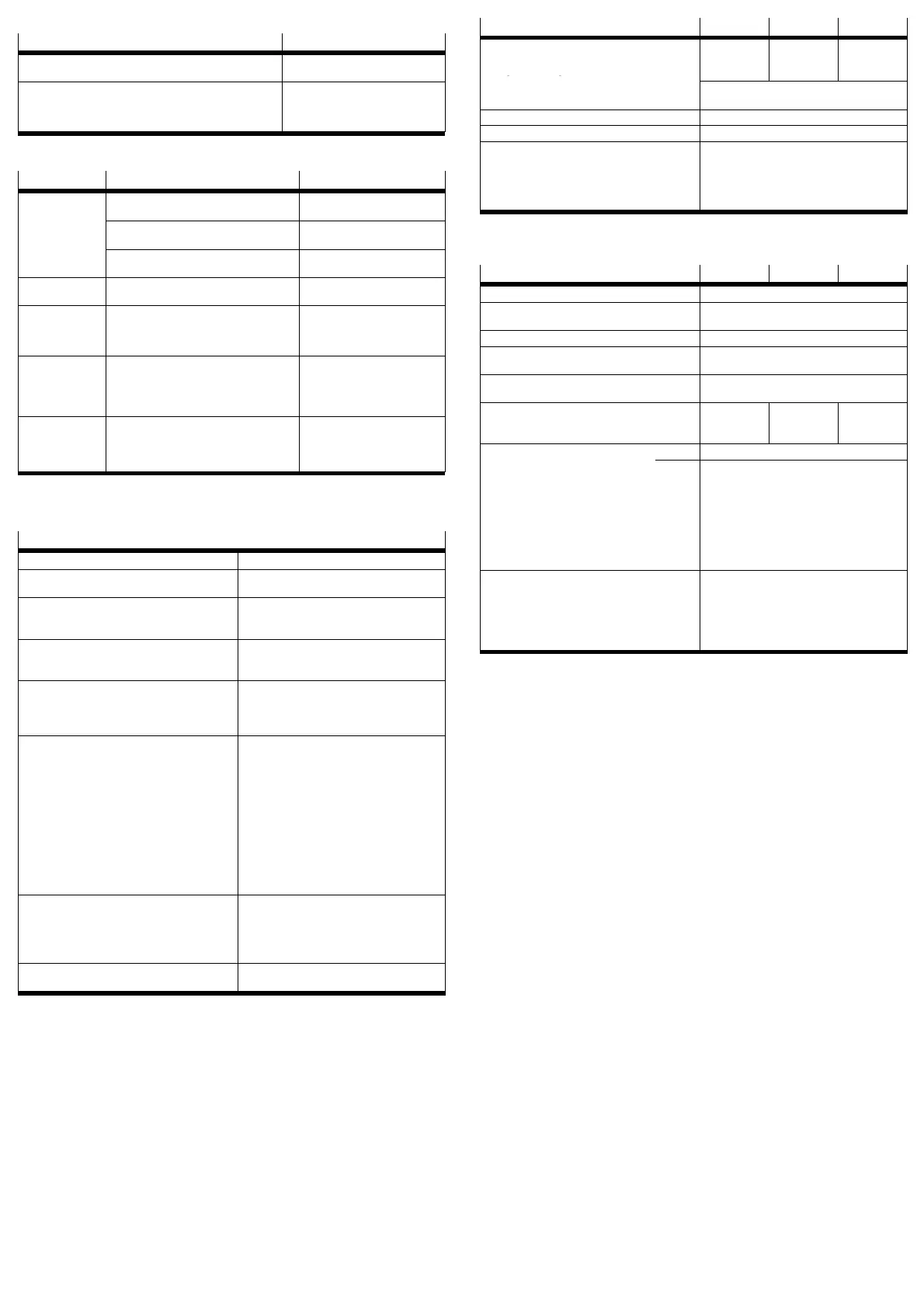

13 Technical data

General data

Design

Propor tional pressure regulator

Mounting position Any, preferably horizontal

(display components facing upwards)

Medium Filtered, unlubricated compressed air (grade

of filtration min. 40 m), no condensation

permissible.

Protection class IP 65 when mounted, with tightened mount

ing screws, in connection with plug socket

according to Accessories".

Perm. temp. range

Ambient

Medium

Storage

[°C]

0 ... +50

+10 ... +50

10 ... +70

Vibration and shock

Vibration

Shock

The following data does not apply to

mounting the VPPM... to the angle bracket

VAME−P1−A.

Tested according to DIN/IEC 68/EN 60068

part 2−6;

for wall mounting:

0.35 mm path at 10 ... 60Hz,

5g acceleration at 60 ... 150Hz

Test e d according to DIN/IEC 68/EN 60068 part

2−27;

for wall mountin g:

±30 g at 11 ms duration; 5 shocks per direction

Materials

Housing

Cap

Seals

Lubrication

Al wrought alloy

PAXMD6−GF50/gr−P, PA6−GB20,GF10/gr−P

NBR

Silicone−free

Weight [g] 1/8": 400

1/4": 560

Fig.37

Pneumatics data 2 bar type 6 bar type 10 bar type

Pressure ranges

Perm. supply pressure

Regulation range

[bar]

0 ... 4

0,02 ... 2

0 ... 8

0,06 ... 6

0 ... 11

0,1 ... 10

Supply pressure p1 at least 1 bar over output

pressure p2

Total leakage when new [l/h] < 5

Ports G1/8" (1/8 NPT), G1/4" (1/4 NPT)

Nominal size

Pressurisation

Exhaust

[mm]

with 1/8": 6

with 1/4": 8

with 1/8": 4.5

with 1/4": 7

Fig.38

Electrics data 2 bar type 6 bar type 10 bar type

Electrical connection Pin contact M12x1, 8−pin

Perm. operating voltage [V DC] 21.6 ... 26.4 V DC (perm. residual ripple

max. 10 %)

Max. electrical power consumption [W] 7

Power rating of digital switching out

put D3 (PIN 8 in el. connection)

[mA]

Max. 60

Max. perm. supply and signal line

length

[m]

10

Overall accuracy

Standard (2 %) +0.5 x Hysteresis

Class S1 (1 %) +0.5 x Hysteresis

[bar]

0.045

0.025

0.135

0.075

0.225

0.125

Hysteresis 0.5 % Full scale

Voltage boy VPPM−...−V1.−...C1

Setpoint variable

Input resistance(setpoint value)

Load of actual value output

Current type VPPM−..−A4.−...C1

Setpoint variable [mA]

Input resistance(setpoint value)

Load of actual value output []

[V DC]

[k]

[k]

[m A]

[ ]

[ ]

0 ... +10

10

min. 2

4 ... 20

250

Max. 500

Electromagnetic compatibility (EMC)

interference emission and resis

tance

See declaration of conformity

è www.festo.com

CE conformity for industrial installations

fulfilled.

Fig.39

Loading...

Loading...