- 23 -

English

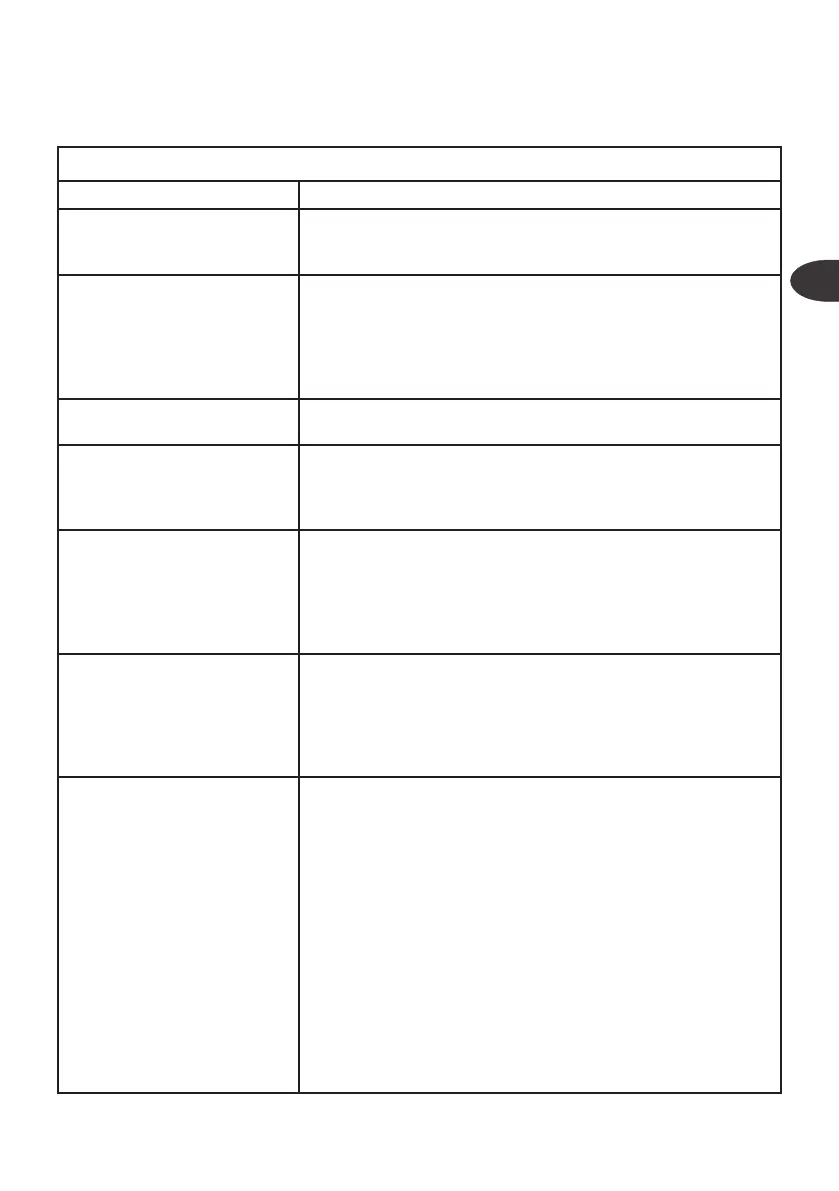

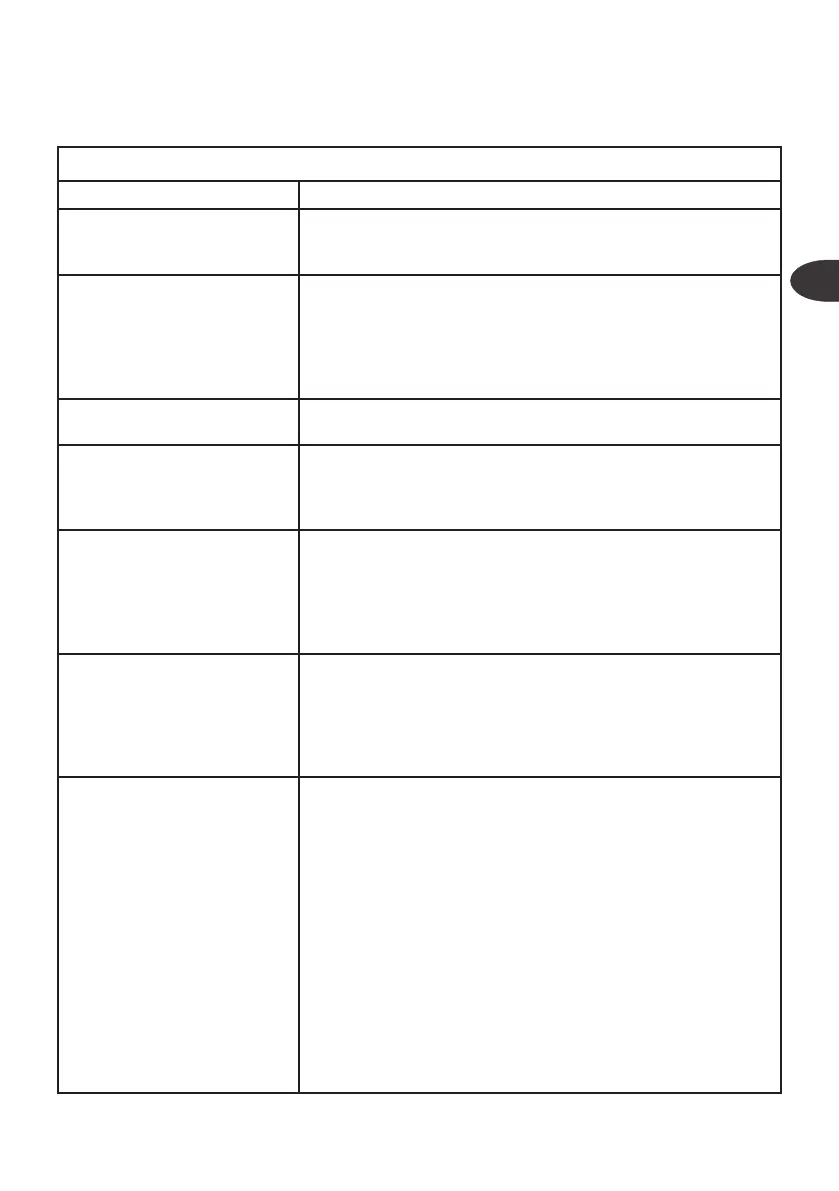

11 - FAULT MANAGEMENT

FAULT TABLE

Anomaly Intervention

Input pressure alarm

The alarm is triggered by an input pressure under 0.5 bar when

the machine is not in water delivery mode. Check the water supply

circuit and for possible shut-off taps closed.

Input ow rate alarm

(Ro-Check only)

The alarm is triggered by an input pressure under 0.5 bar when the

machine is in water delivery mode. Check the water supply circuit for

an inadequate size in particular of the tubing or ow restrictions in

general. To check the circuit, install a pressure gauge on the supply

tube immediately before the machine. Pressure in the delivery phase

must be at least 0.5 bar.

Pump not working alarm

(Ro-Check only)

The alarm is triggered by a null pump pressure in the delivery phase.

Check the pump and motor, replace the faulty part if necessary.

Low pressure pump alarm

(Ro-Check only)

The alarm is triggered by a detected pump output pressure that is too

low. Check if the pump bypass is correctly adjusted (if an intervention

is necessary, follow the instructions in the manual carefully) and if

the pump is working properly.

Pump pressure too high

(Ro-Check only)

The alarm is triggered by a detected pressure over 10 bar after the

pump.

• Check if the drain is obstructed.

• Check if the membranes are exhausted (low permeate ow rate).

• Check if the pump bypass is correctly adjusted (if an intervention

is necessary, follow the instructions in the manual carefully).

Permeate quality alarm

(Ro-Check only)

The alarm is triggered by a conductivity of the permeate water that

is over the set parameter. Check if the set value is compatible with

the characteristics of the machine and the input water. Check if the

mixer is adjusted correctly. If rejection is under 90% with the mixer

fully closed, the membranes may be exhausted. If necessary, replace

the membranes in compliance with the system manual

Permeate ow rate alarm

(Ro-Check only)

The alarm is triggered by a ow rate of the permeate water that is

under the set parameter. The permeate ow rate greatly depends

on various factors

• Temperature (see manual)

• Input water conductivity. When the xed residue increases, the

osmotic pressure increases, the permeate ow rate decreases.

• Vessel input pressure

• Permeate circuit pressure. The machine can work safely obtaining

pressure in the output circuit, if the system is appropriately

designed, but the ow rate will be reduced as a result.

• Membrane life: working hours, period of inactivity, rapid work

cycles can reduce the permeate ow rate

For a correct measurement of the machine performance, the

permeate duct pressure must be under 0.1 bar, the pump pressure

must be 8.5 bar and the measurement must be converted for 25°C

using the specic tables.

Loading...

Loading...