5.18 ELECTRONIC LEVEL DRAIN

Instead of the usual drain system (a solenoid valve controlled by means of electronic instrument); an

electronic level controlled drain can be installed as option. This drain consists of a condensate accumulator

where a capacitive sensor continuously checks the level of the liquid: as soon as the accumulator is filled,

the sensor passes a signal to the electronic control and a diaphragm solenoid valve will open to discharge

the condensate. For a complete condensate discharge the valve opening time will be adjusted exactly for

each single drain operation to avoid wasting air. No Y-shaped filter is installed and no adjusting is required.

A service valve is installed before the electronic drain in order to make check and maintenance operation

easy.

AT DRYER START-UP VERIFY THAT THIS VALVE IS OPEN.

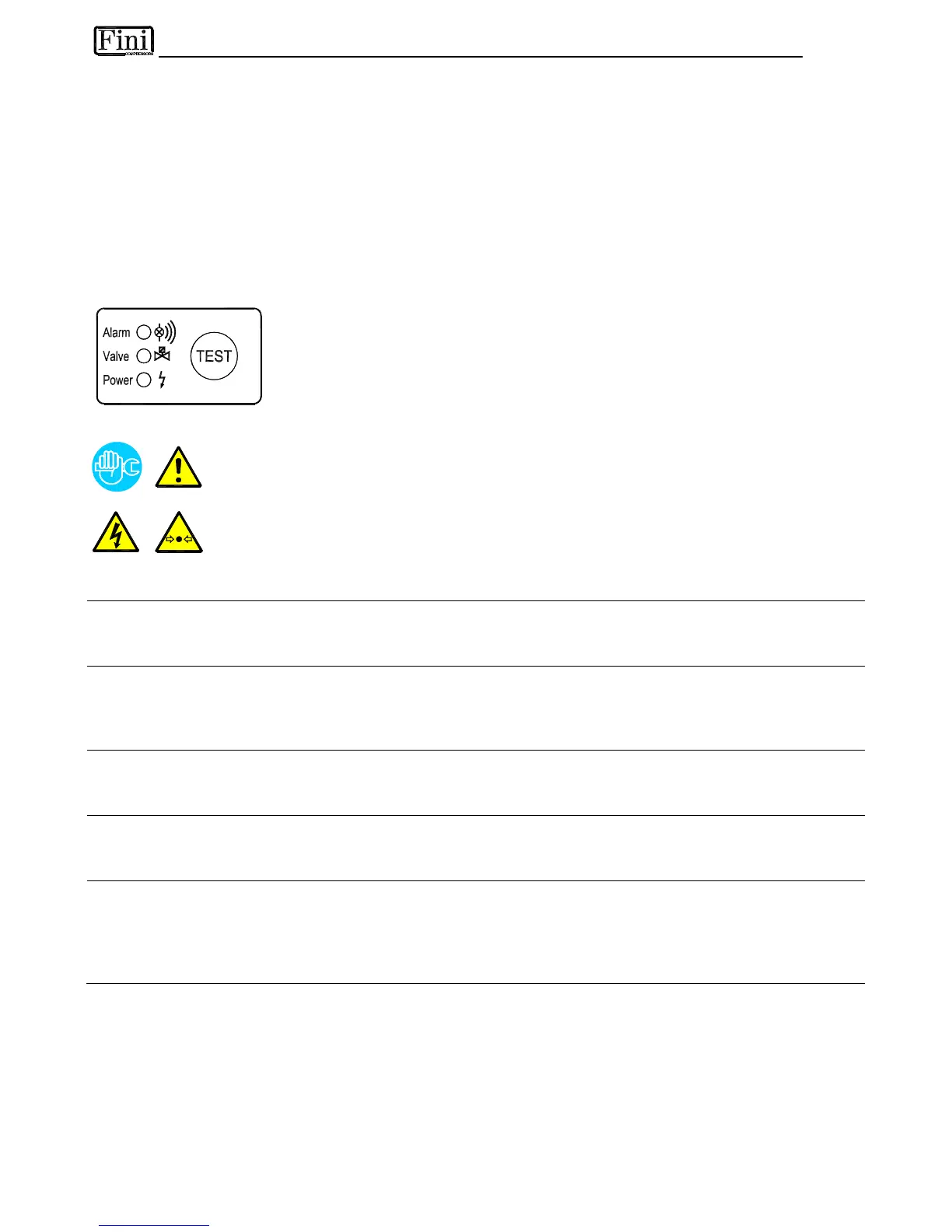

CONTROL PANEL

The control panel here illustrated allows checking of drain working.

Power : LED ON - drain ready to work / supplied

Valve : LED ON - membrane solenoid valve open / discharging

Alarm : LED ON - drain in alarm condition

Test : button - discharge test (keep pushed for 2 seconds)

TROUBLESHOOTING

Only qualified personnel should perform troubleshooting and or maintenance operations.

Prior to performing any maintenance or service, be sure that:

• no part of the machine is powered and that it cannot be connected to the mains supply.

• no part of the machine is under pressure and that it cannot be connected to the compressed

air system.

•

Maintenance personnel have read and understand the safety and operation instructions in

this manual.

SYMPTOM POSSIBLE CAUSE - SUGGESTED ACTION

No led lighting up. Verify that the system is powered.

Verify the electric wiring (internal and/or external).

Check internal printed circuit board for possible damage.

Pressing of Test button,

but no condensate

discharge.

The service valve located before the drain is closed - open it.

The dryer is not under pressure - restore nominal condition.

Solenoid valve defective - replace the drain.

The internal printed circuit board is damaged - replace the drain.

Condensate discharge

only when Test button is

pressed.

The capacitive sensor is too dirty - open the drain and clean the sensor

plastic tube.

Drain keeps blowing off

air.

The diaphragm valve is dirty - open the drain and clean it.

The capacitive sensor is too dirty - open the drain and clean the sensor

plastic tube.

Drain in alarm condition. The capacitive sensor is too dirty - open the drain and clean the sensor

plastic tube.

The service valve located before the drain is closed - open it.

The dryer is not under pressure - restore nominal condition.

Solenoid valve defective - replace the drain.

NOTE : When the drain is in alarm condition, the diaphragm solenoid valve will open 7.5 sec every 4 min.

Loading...

Loading...