SYSTEM FILLING, TESTING AND COMMISSIONING

* Before proceeding to filling, ensure that electricity supply is switched off at mains

to avoid any possibility of time switch operating and passing power to appliance

prior to filling.

Filling and Testing

Check that all connections, especially compression joints, are fully tightened. Re-check and

ensure that pressure vessel air charge is correct, then fill system with water via filling system

used. Turn off water supply before system pressure reaches safety valve operation point of

3 bar. (Say 2 to 2.5 bar). Vent system via all manual air vents including circulating pumps,

boiler, radiators, system high points. etc. Check that dust caps are loosened on auto air vents,

keep constant check on system pressure gauge (fitted to control panel). If pressure has dropped

readmit water to above pressure. Ensure all appropriate boiler and system valves are open.

With water supply turned off, thoroughly flush out boiler and system to remove all foreign

matter before allowing boiler and pumps to operate. If in doubt drain system and repeat above

procedure. At this stage flushing-out water should be clean and clear of all foreign

matter.

Refill the system and again vent at all points as described above. Examine the complete system

for water leaks having pressurised it to 1.5 - 2.5 bar. Correct any leaks, then check operation of

safety valve by admitting further water until this valve operates. This should occur when system

pressure rises to between 2.7 and 3.3 bar. When satisfied with valve operation, and with mains

water still turned off, draw off sufficient water until initial system design fill pressure (P

i

). (cold

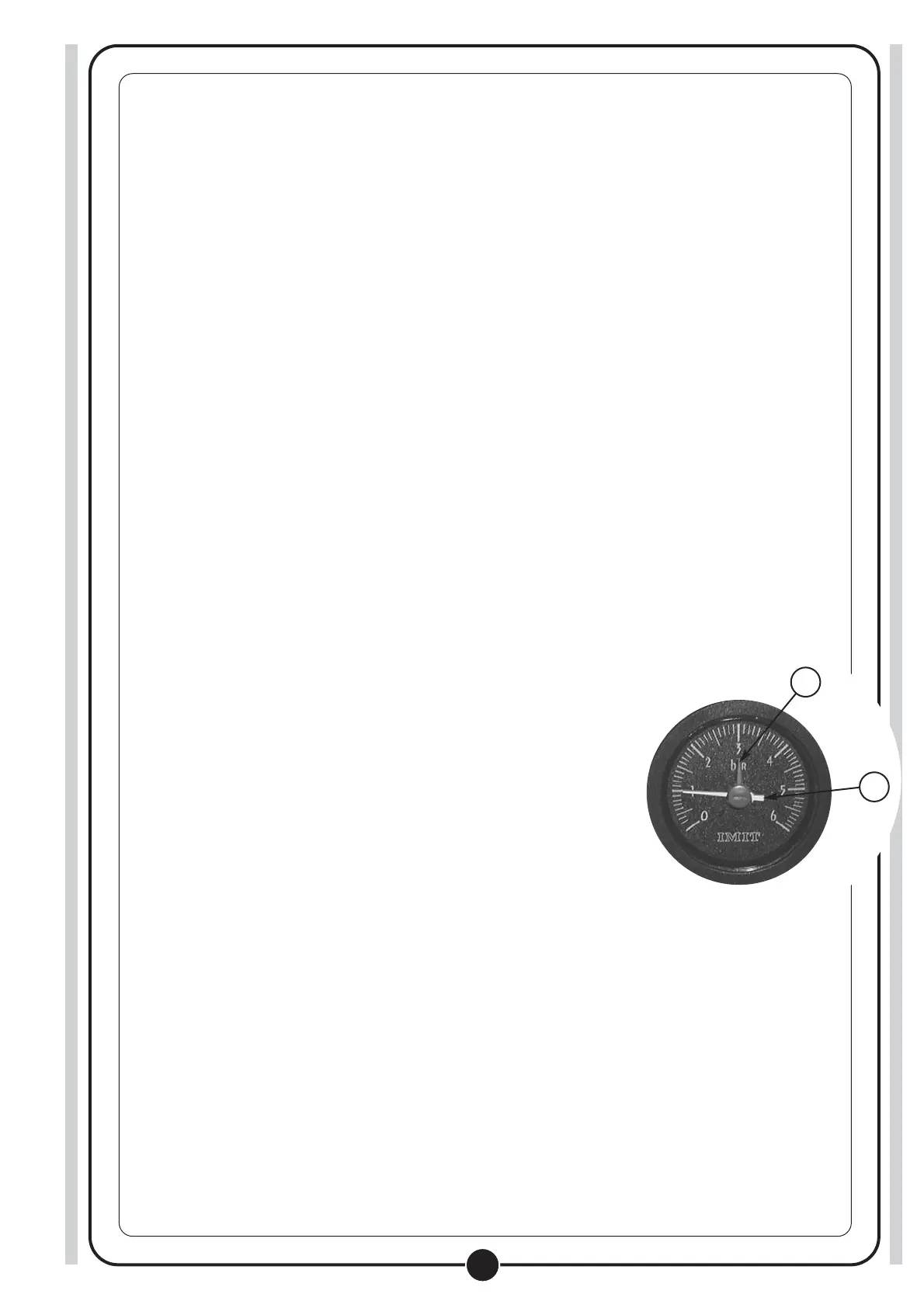

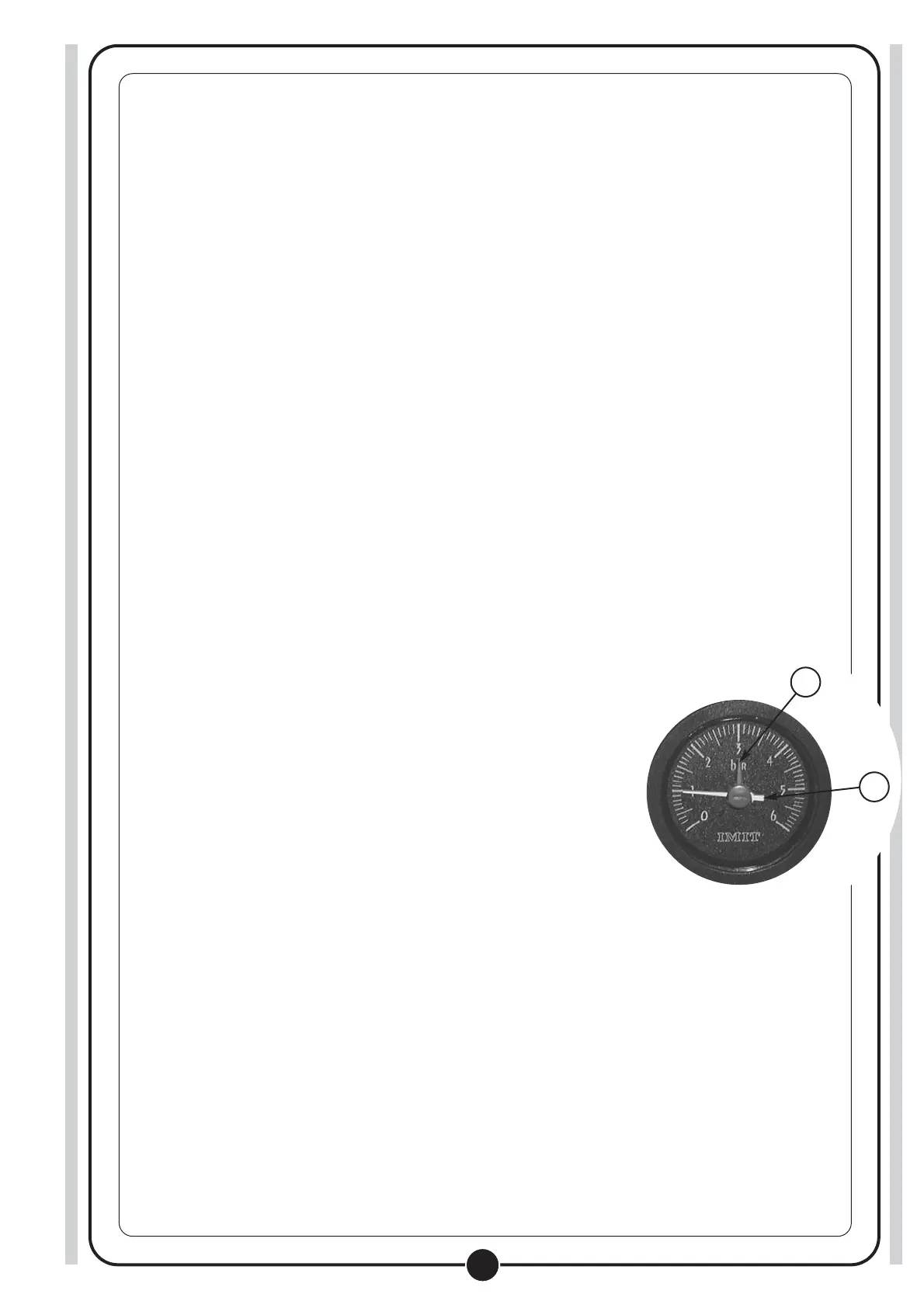

fill) is established (0.5 - 1.5 bar - as calculated for system). The red pointer B

on pressure gauge should then be set at this initial system design pressure

(P

i

), i.e. system static head +0.3

Remember that initial cold fill pressure can only be checked when

system water has properly cooled down. Check that final

operating pressure (P

f

) is under 2.5 bar with all radiators turned

on and up to highest working temperature. Should system

operating pressure exceed this, check:

1. That initial cold fill pressure is correct and , if additional

expansion vessel is fitted, that pressure is equal in each vessel,

2. That expansion vessels are sized correctly.

Special attention should be given to existing heating systems where Firebird Combi

boiler has replaced an existing unit. Extra effort should be made to ensure that all original

pipe work and radiators are repeatedly flushed. If possible use a proprietary cleansing

agent suitable for system as loosened scale and foreign matter can

seriously reduce domestic hot water performance and pump

efficiency.

Use corrosion inhibitor of suitable type.

37

B

A

Loading...

Loading...