CONDENSATE PLUME DISPERSAL

When choosing the location for a condensing boiler,

special consideration must be given to the positioning of

the flue terminal. Care should be taken to locate it so as to

prevent either the end user or their neighbours perceiving

the plume to be a nuisance.

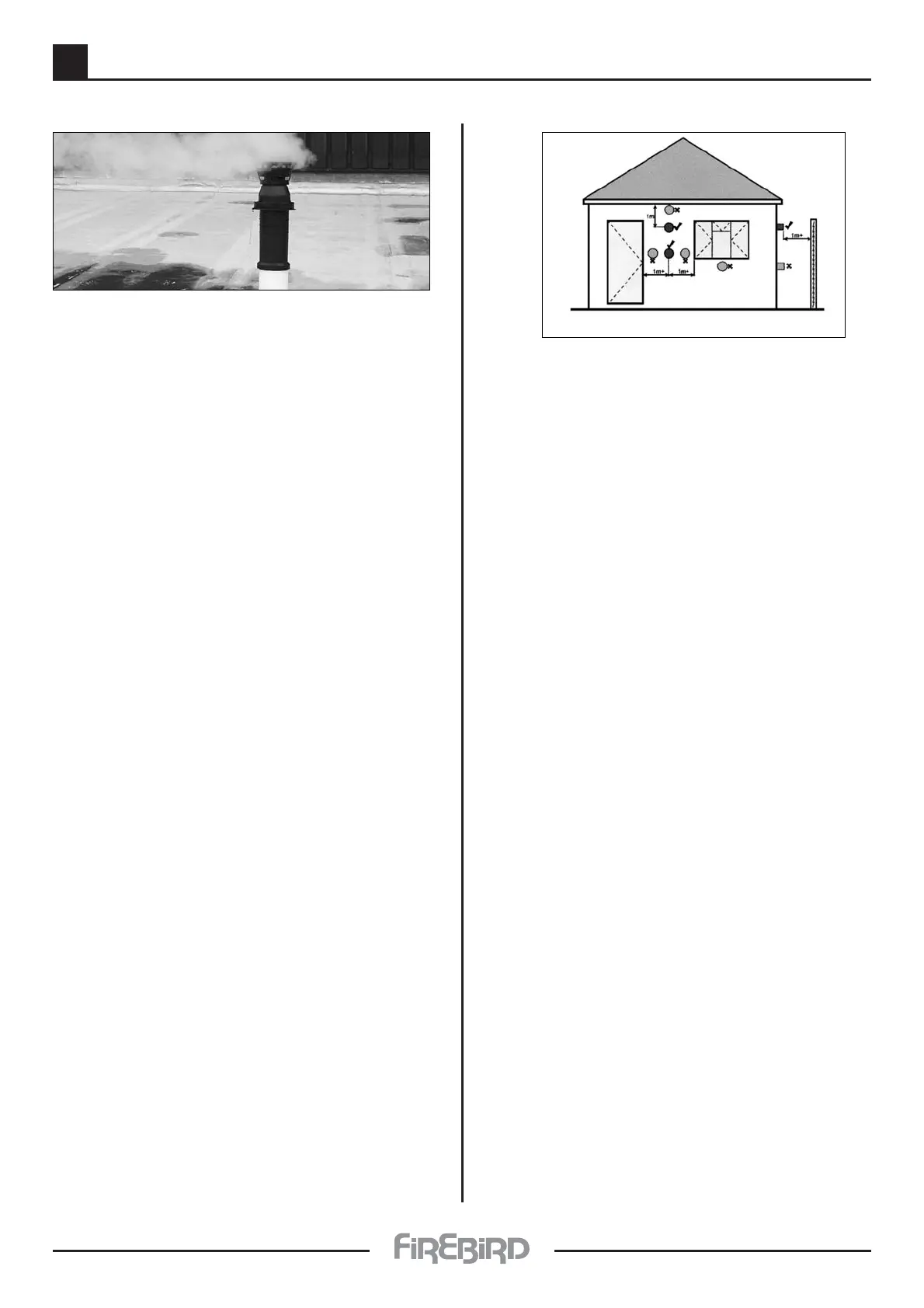

It should be noted that the normal statutory clearances

required around low level flue terminals may not be

sufficient to cope with plume dispersal from a condensing

boiler. The following points should be considered:

1. Plumes can extend out horizontally and can also drift

out to the sides and above the terminal. Care needs

to be taken, therefore, to avoid the plume reaching

adjacent surfaces, particularly windows and

neighbours dwellings.

2. Flue terminals need to be located where air can pass

freely across them to disperse vapours.

3. The effect of the moisture generated must be

considered in relation to the possible corrosion of

metal parts it might reach and to the possible

formation of ice on pathways in freezing conditions.

4. Keep flue terminals a minimum of 1m (horizontally)

from openings in the building.

5. Do not install flue terminals directly below a window.

6. Do not install flue terminals next to a door.

7. Do not install flue terminals within 1m of ventilated

soffits or eaves.

8. Keep flue terminals at least 2.5m away from a surface

or boundary facing the terminal.

9. In certain circumstances the installation of a plume

dispersal extension to the flue may be unavoidable.

This takes the plume exhaust from the boiler up and

away from any obstruction, door or window opening

and will also prevent the risk of re circulation of the

plume gasses into the air intake of the burner (on

next page).

10. Follow the appliance manufacturer's instructions.

FLUE TERMINAL

4

18

4.5 - FLUE SYSTEMS - REGULATIONS & GUIDELINES

CONVENTIONAL FLUE SYSTEMS

IMPORTANT

The Firebird condensing boiler must not be installed

with existing flue systems.A flue system suitable for wet

flues must be used. If a flue system which is unsuitable

is used it will invalidate the warranty.

Because of the high operating efficiencies of the

Firebird condensing boilers and low flue gas

temperatures, it is necessary to pay extra special

attention to the flues and chimneys.

Existing chimneys must be lined with a liner certified

as suitable for condensing oil boilers by a flue

manufacturer.

Twin wall insulation must be used for external

applications, with seals and stainless steel inner skin.

Only vitreous enamel or high grade stainless steel can

be used between boiler and chimney in an internal

installation, aluminium or asbestos type material must

not be used (vitreous enamel must not be cut).

Condensate must be able to run back into the flue

chamber of the boiler and not escape, as up to 1.5 ltr. of

condensate can be produced in a conventional flue. No

trap is required in the flue system.

The terminal must be positioned to avoid combustion

products entering the building and as per Building

Regulations. Refer to BS5410 Part 1: 2014 OFTEC

installation requirements book 4.

Every individual concerned with any aspect of

installation should be deemed as competent, and be

aware of all current National and Local Government

Standards and Building & Installation Regulations.

Loading...

Loading...