Firebird Condensing Boiler

4

22

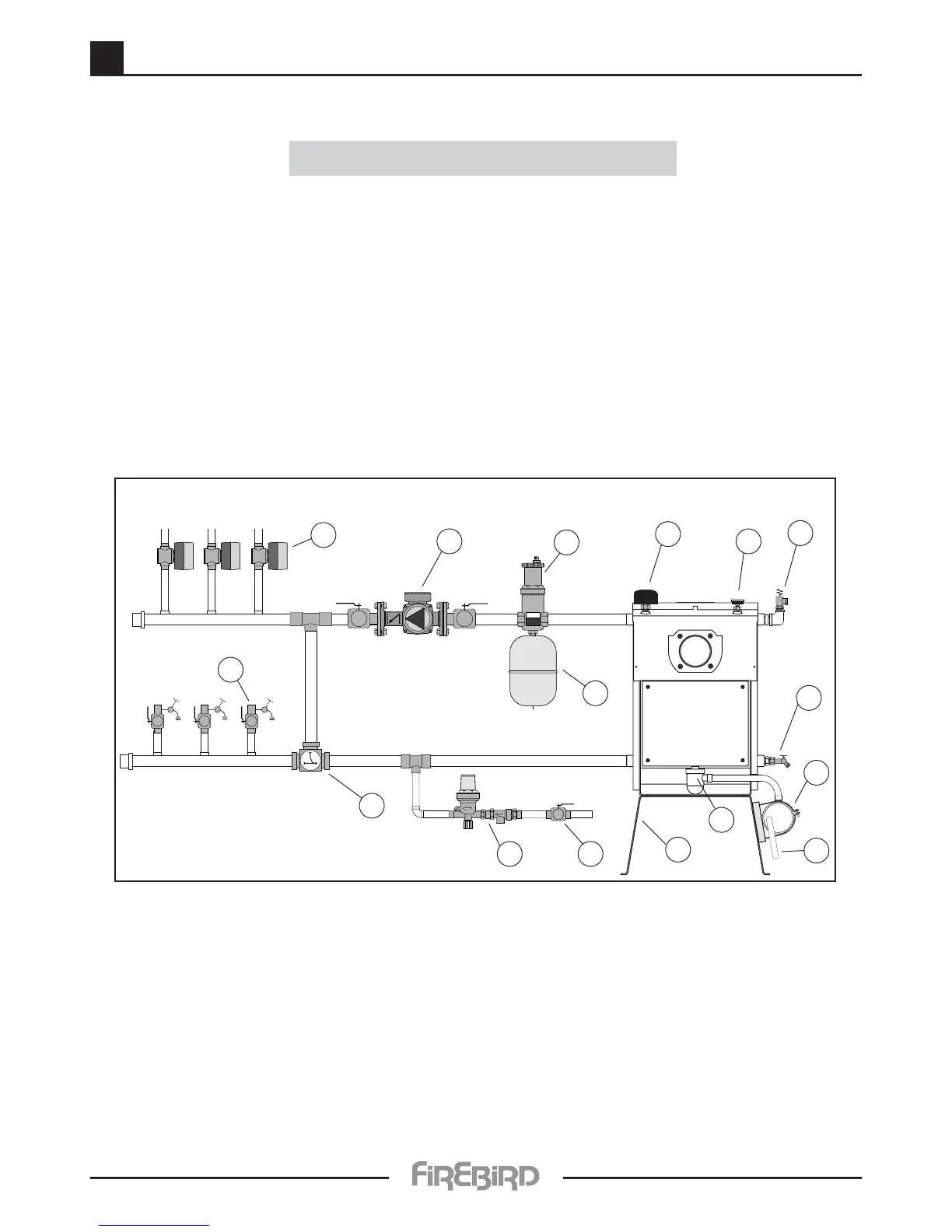

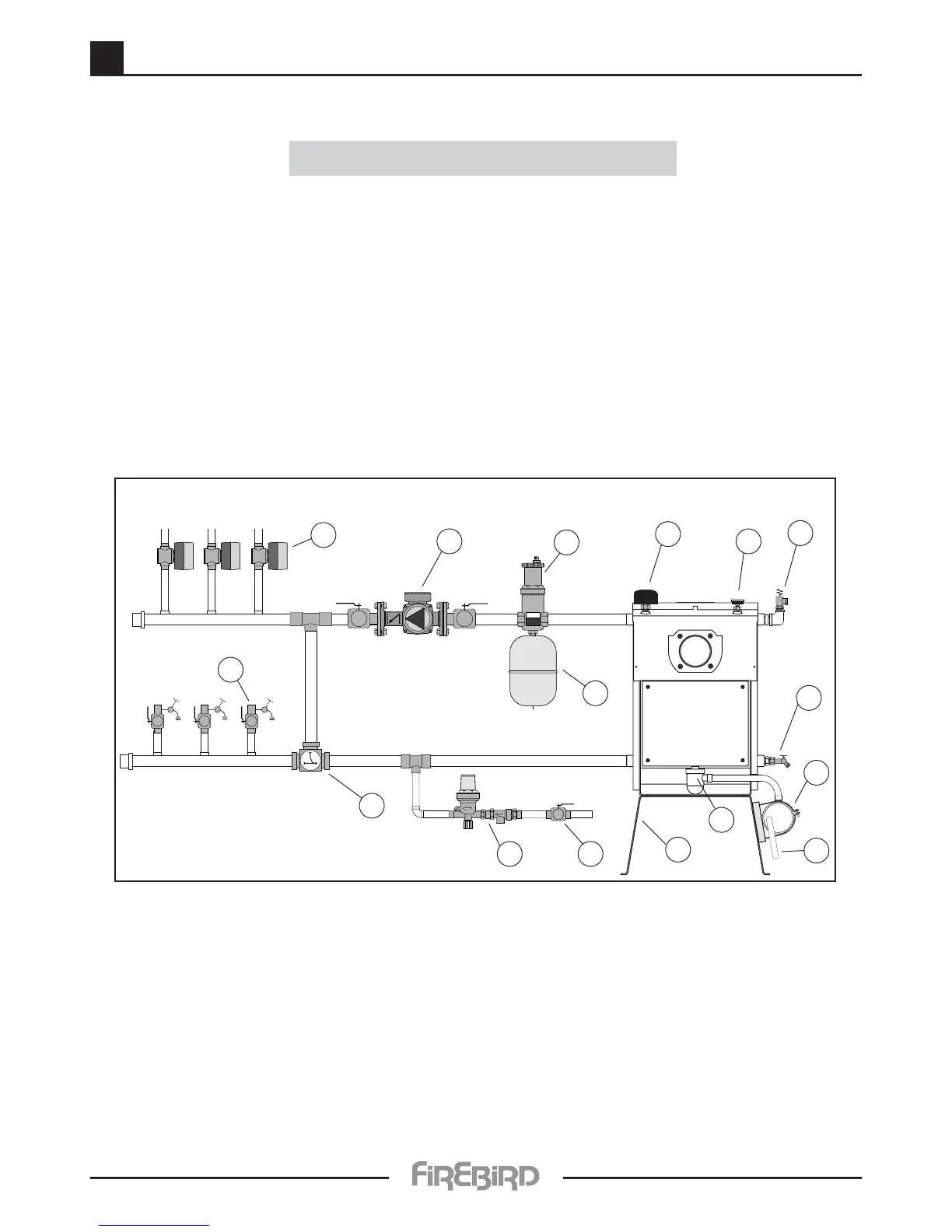

4.4 - BOILER PIPING

LOW TEMPERATURE HEATING SYSTEMS

Like many other condensing appliances the Firebird boiler will offer its highest efficiency when installed on a low temperature

heating system. Ideally, return water temperatures should be kept below 140 degrees Fahrenheit to aid the condensing

process. Care should be taken that the return water temperatures do not consistently fall below 110 degrees Fahrenheit.

If it is possible for the return water to fall below 110 Fahrenheit, a boiler bypass must be installed. Please refer to the piping

diagram on the following page for piping of the bypass. When replacing an older style boiler, it is important to make sure that

the system has been properly flushed of all debris and contaminants remaining from the previous system. To ensure the

highest possible system efficiency it is recommended to perform a chemical flush of the entire system. Once the system has

been filled it is required to install the X100 corrosion inhibitor supplied with the boiler. Failure to install the X100 corrosion

inhibitor will void the warranty of the boiler.

The following piping diagrams show basic layouts for proper installation of the boiler. These layouts are

not the only acceptable manner in which the boiler can be piped, but are supplied as a guideline.

4

1

2

3

5

6

8

7

910

11

13

14

12

15

15

Low Temperature Central Heating System

Legend

1 - Pressure Relief Valve

2 - Tridicator

3 - High Limit Control

4 - Air Elimination

5 - System Circulator

6 - Zone Valves

7 - Purging Stations

8 - Expansion Tank

9 - Back Flow Preventer / Auto Fill

10 - Ball Valve (to shut auto fill)

11 - Boiler Stand (optional)

12 - Condensate Trap

13 - Boiler Drain

14 - Condensate Neutralizer

15 - Condensate Drain

(piped to drain or pump)

16 - Boiler protection mixing valve

17 - Boiler Circulator

Loading...

Loading...