SELECTING THE PROPER AMPERAGE

The electrode type and thickness of the metal work-piece determine the

amount of heat needed in the welding process. See Figure 5 for bead examples

of heat based on rod size. Heavier and thicker metals require more heat or

amperage. Refer to a rod and amperage guide or experiment on scrap metal.

When you weld with proper rod your results will be:

1. Bead will lay smoothly over the workpiece without ragged edges.

2. Base metal puddle will be as deep as the bead that rises above it.

3. The welding operation will make a crackling sound similar to the sound of

frying eggs.

When you weld with rod that is too small your results will be:

1. Bead will be high and irregular.

2. Arc will be difficult to maintain

When you weld with rod that is too large your results will be:

1. Arc will burn through light metals.

2. Bead will undercut the work.

3. Bead will be flat and porous.

4. Rod may freeze or stick to the workpiece.

The rate of travel over the workpiece affects the weld. To ensure proper penetra-

tion and enough deposit of rod, move the arc slowly and evenly along the weld seam.

WELDING PARAMETERS

Following tables provide recommended welding parameters for various welding jobs using various welding types.

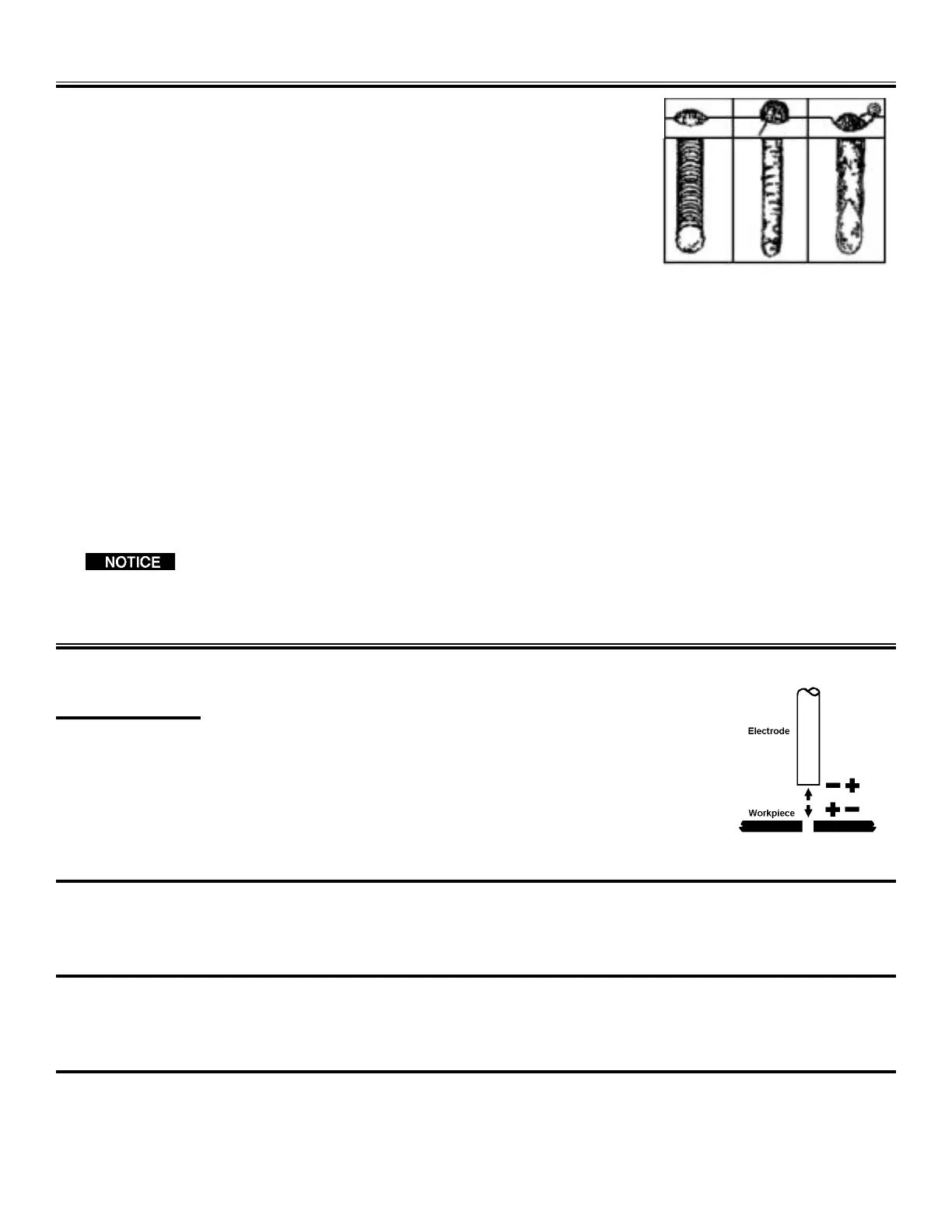

AC WELDING

Alternating current continuously changes polarity.

Ideal Current For:

• Down Hand Heavy Plate.

• Fast Fill.

ROD METAL

AWS ROD NO. USE SIZE AMPERAGE THICKNESS

E6013 Down Hand 1/16” Min. - 40 amps Min. - 1/8”

General Purpose Mild Steel 3/32” 30 - 80 amps 1/16” - 1/4”

General Purpose 1/8” 70 - 160 amps 1/8” - 1/2”

Work on Mild Steel 5/32” 120 - 180 amps 1/4” - Up

E7014 New Steel Fabrication 5/64” 30 - 100 amps Min. - 1/8”

General Purpose 3/32” 40 - 100 amps 1/16” - 1/4”

Iron Powder and All Build Up Worn Surfaces 1/8” 100 - 170 amps 1/8” - 1/2”

other AC Rods 5/32” 140 - 150 amps 1/4” - Up

E6011 Down Hand 1/8” 100 -150 amps 1/8” - 1/2”

General Purpose Mild Steel 5/32” 120 - 170 amps 1/4” - Up

General Purpose

Work on Mild Steel

13

Figure 5: Bead Heat Requirement

Samples

Loading...

Loading...