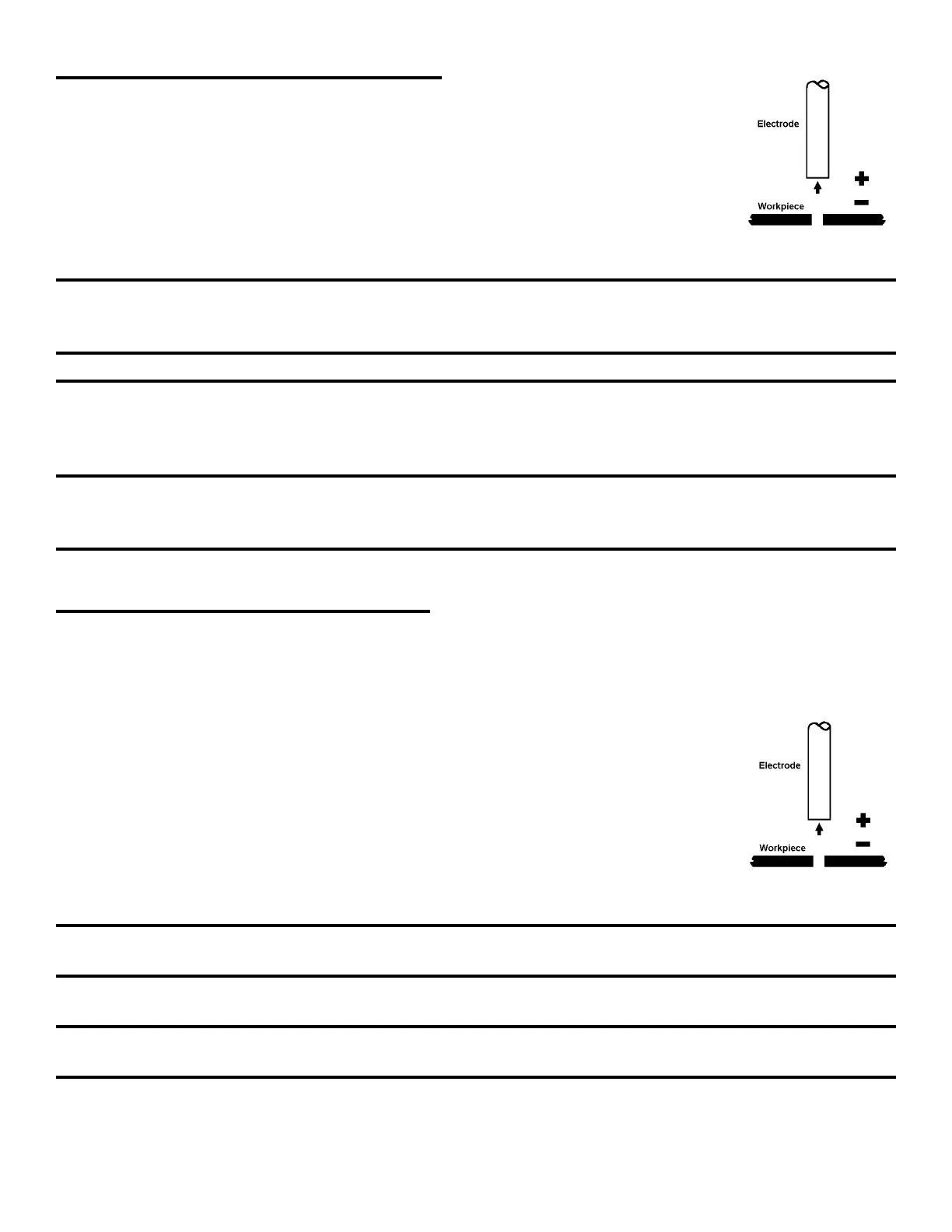

DC STRAIGHT POLARITY WELDING

The electrode in DC straight polarity (DCSP) welding is negative and the work surface is

positive. The current flow is from the electrode to the work.

Ideal Current for:

• Hard Facing.

• Build Up - Heavy Deposits.

• Cutting Steel.

ROD METAL

AWS ROD NO. USE SIZE AMPERAGE THICKNESS

R52 Hard Surface

General Purpose Tillage Tools 1/8” 80 - 140 amps 1/16” - Up

Subject to Impact and Abrasion

R88 Tung Rod To Resist Serious Abrasion 1/8” 70 - 90 amps 1/16” - Up

ARC CUTTING Cutting and Drilling All Metals 1/8” 80 - Max. 1/16” - Up

Drilling All Metals

E6011 Deep 1/8” Maximum Dial Any Thickness

Penetrating 5/32” Setting

ARC GOUGING

E6011 Deep Arc Gouging 5/32” Maximum Dial Any Thickness

Penetrating

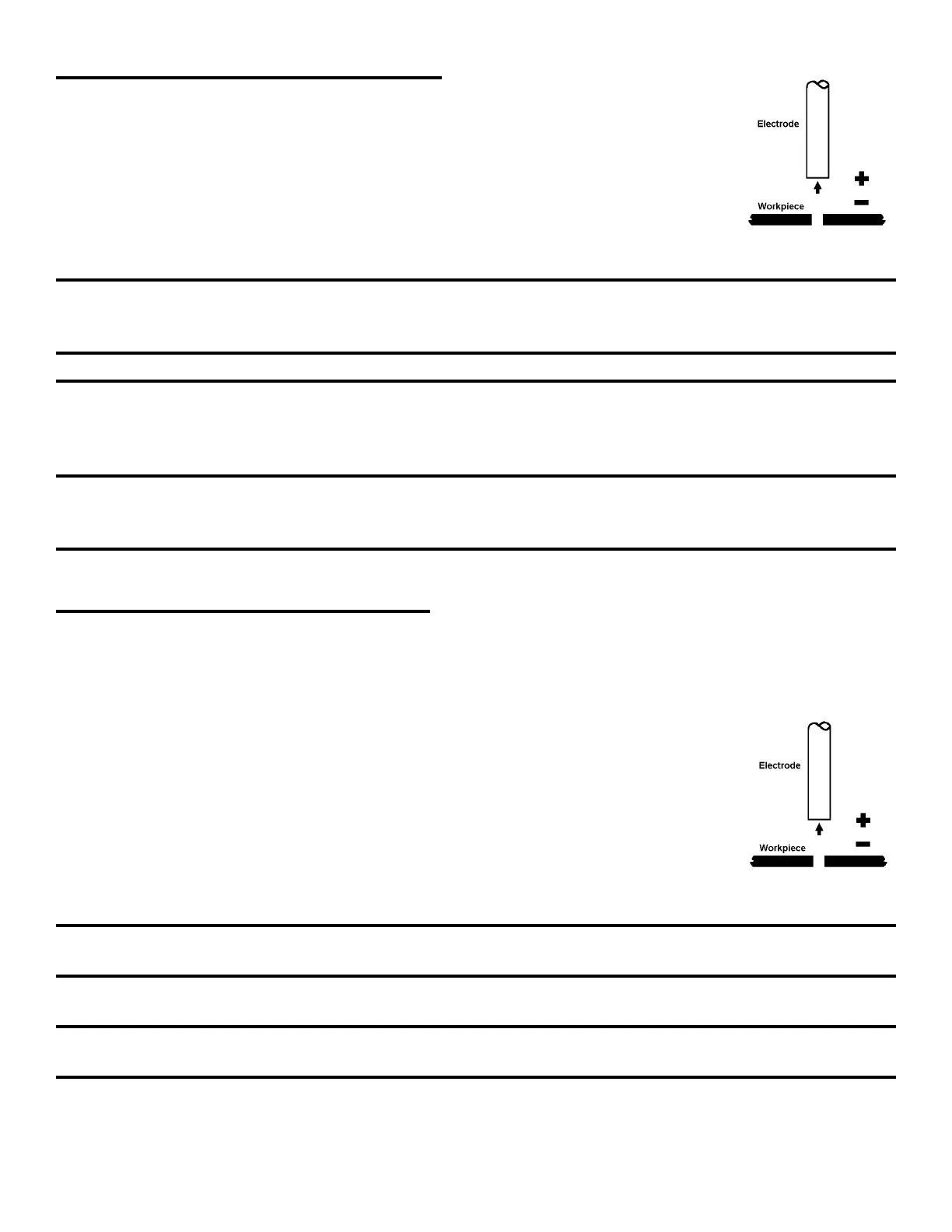

DC REVERSE POLARITY WELDING

The electrode in DC reverse Polarity (DCRP) welding is positive and the work surface is negative. The current

flow is from the work to the electrode.

Ideal Current For:

• Overhead.

• Vertical.

• Cast Iron Welding.

• Heavy Aluminum.

• Rivet Welding.

• Sheet Metal.

• Low Hydrogen Welding.

• Arc Bronze Rod.

ROD METAL

AWS ROD NO. USE SIZE AMPERAGE THICKNESS

E6011 Deep Overhead and Vertical 1/8” 80 - 150 amps 1/8” - 1/2”

Penetrating Welding or Rusty Metals 5/32” 100 - 170 amps 1/4” - Up

E7018 Low High Carbon Spring Steel 1/8” 80 - 140 amps 1/8” - 1/2”

Hydrogen or Cast Steel 5/32” 100 - 170 amps 1/4” - Up

ENiCl Nickel Cast Iron 3/32” 50 - 70 amps 1/16” - 1/4”

Machineable 1/8” 80 - 120 amps 1/8” - Up

E308-16 Cast Iron 3/32” 50 - 100 amps 1/16” - 1/4”

Stainless Steel Stainless Steel or Unknown

Metal Max. Strength 1/8” 90 - 150 amps 1/4” - Up

14

Loading...

Loading...