INSTALLATION PROCEDURE

The following instructions must be followed, however

it is recommended that the installation is delayed

until all the building or maintenance work is

completed. Building work near the panel may result

in damage.

Remove the fire panel from the packaging, but retain

this for the future storage of panel parts during

installation.

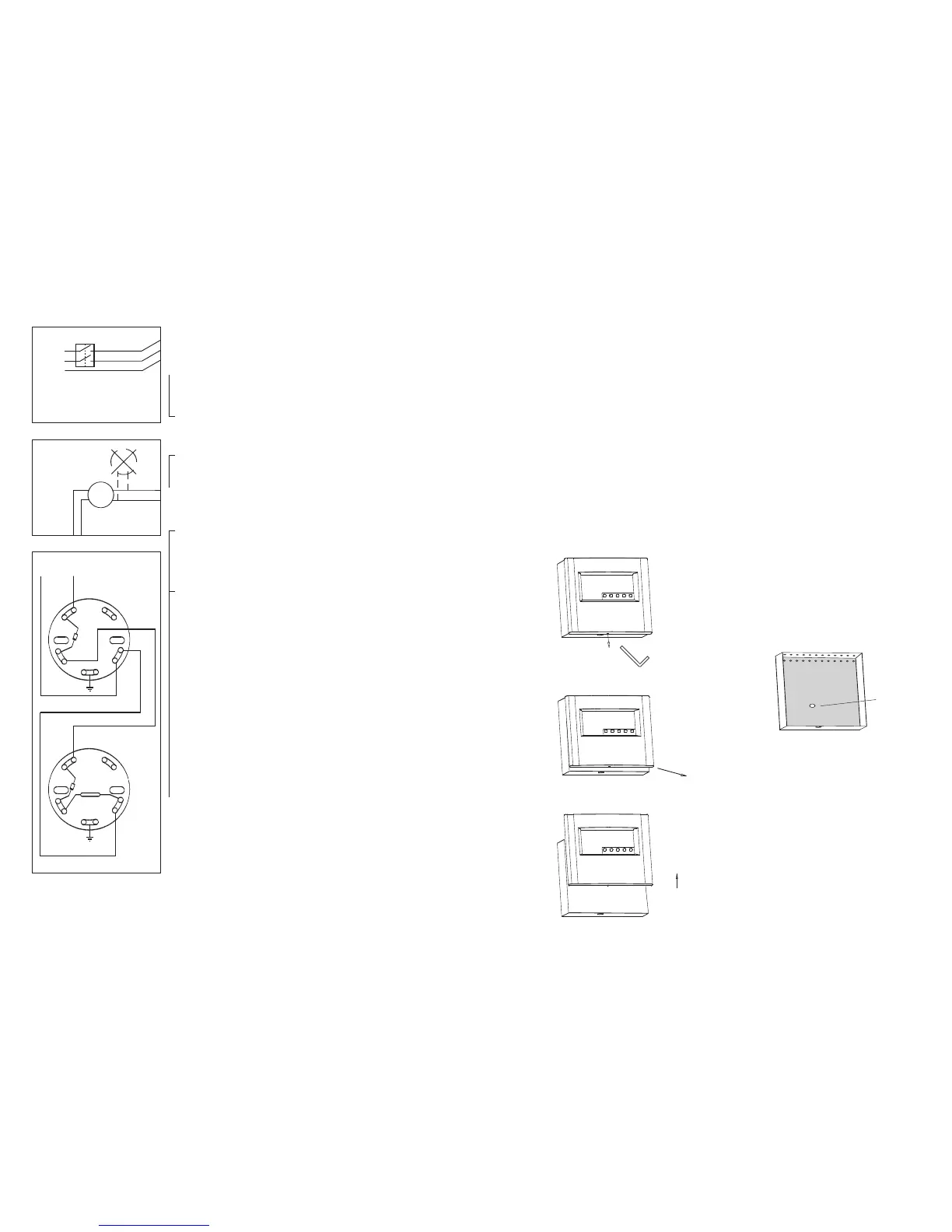

A) To remove the front – remove the screw located

under the bottom edge of the panel using Allen

key provided, pull the bottom edge out then lift

up. Store the panel front face down in the

packing box tacking care of the led light guides

on the back.

B) Box Mounting - Once the cable entry routes have

been decided, remove the appropriate knockouts

situated on the top and back of the box by

carefully knocking out from the inside outwards.

Note the entry point for the mains cable is

through a knockout which is located at the back

of the back box – see below. Ensure that the

back box is securely and flush fitted to the fabric

of the building. The box should be mounted at

such a height that the push buttons and LED’s

are at eye level. When mounting the box take

care not to damage the pcb in the box. Remove

any debris.

C) Feed the required cable into the box then make

off a reasonable working length, (identify each

of the cables).

Conduct all installation tests on

the cables with the detectors and other

electronic devices disconnected. Failure to

observe this could result in serious damage to

the detectors etc.

SYSTEM DESIGN GUIDE

When installing the system the designer should ensure:-

1. The installation complies with the relevant code of practise for

installations.

2. The mains supply is switched via a double pole isolator.

3. All detectors are sighted in accordance with British standard

recommendations.

4. That detector and alarm sounder circuits have NO SPURS.

5. It is recommended that the cabling used for detector and alarm

circuits is 1.5mm

2

Fire Protected, 2-core + screen complying with

BS7629, BS7846 and BSEN60702 (BS6207).

6. That detectors and callpoints used are compatible with the panel,

and that only devices recommended by the supplier are used.

7. The correct end of line component is used on the detection and

alarm circuits (including those not used), These components must be

fitted after the last detector, callpoint or sounder.

8. The total current consumption for each zone of detectors does not

exceed 4mA

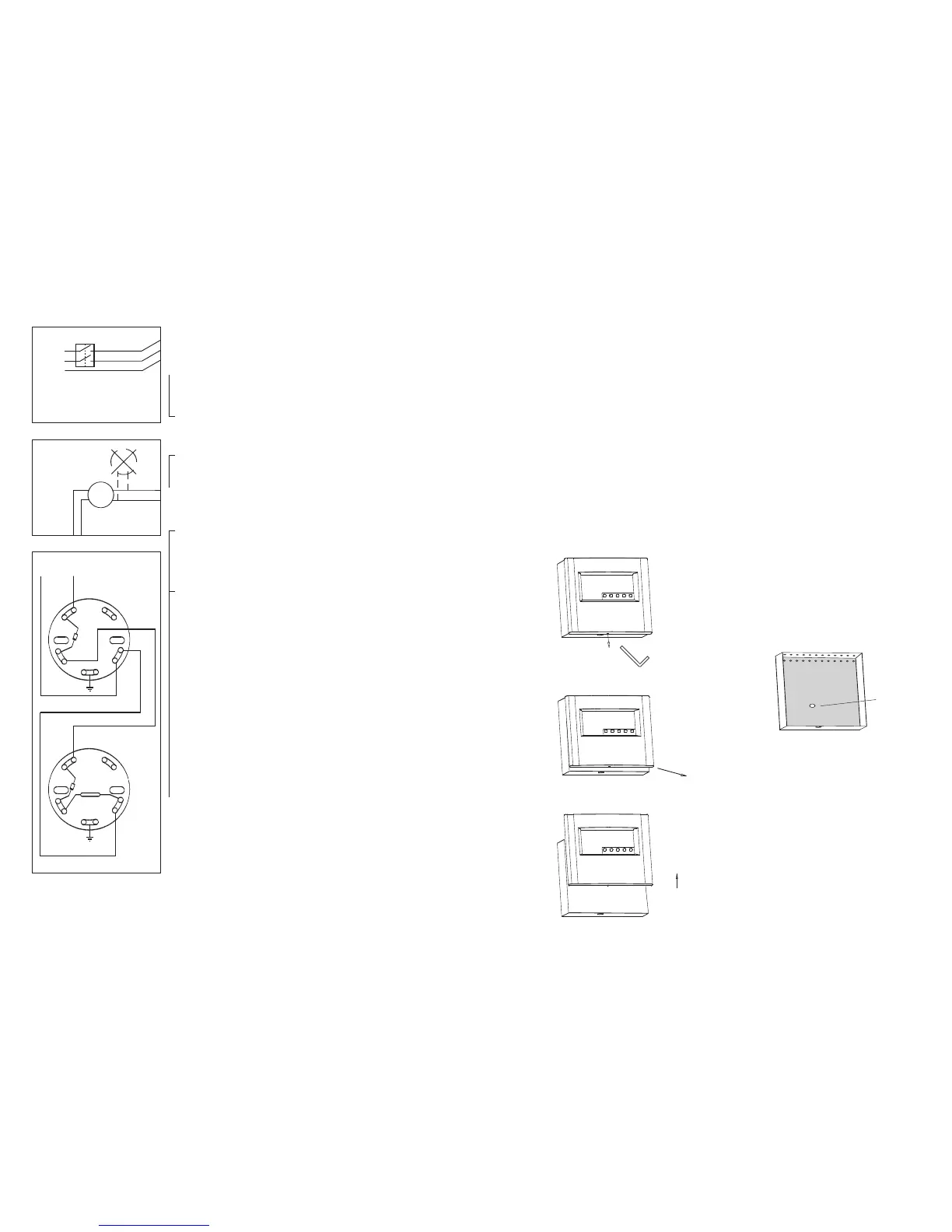

9. The detector bases are connected as shown and must be fitted with a

diode for detector removal fault. Otherwise the removal of a detector

from a base will prevent subsequent detectors and call-points on the

zone from functioning.

10. The sounders must have a series blocking diode with suppression

components fitted that only allows current to flow through the

sounders when the control panel pcb is wired as shown.

11. Sounder current consumption should not exceed the panel

maximum. The maximum load for each set of contacts is 1A, however

the total sounder current should not exceed that shown in table for

panel specification.

12. That if a 24V auxiliary output is used for powering an auxiliary

circuit, the battery standby period is checked to ensure that the

maximum duration required for the installation can still be achieved.

Loading...

Loading...