133 Series

12

*Recommended spare parts.

1. If the 2 in. w.c. to 2 psig / 5 mbar to 0.14 bar springs listed under Type 133L are used in the Type 133H, the pressure ranges will increase by approximately 1 in. w.c. / 2 mbar due to the

weight of the Type 133H parts (assuming that the actuator is installed above the body).

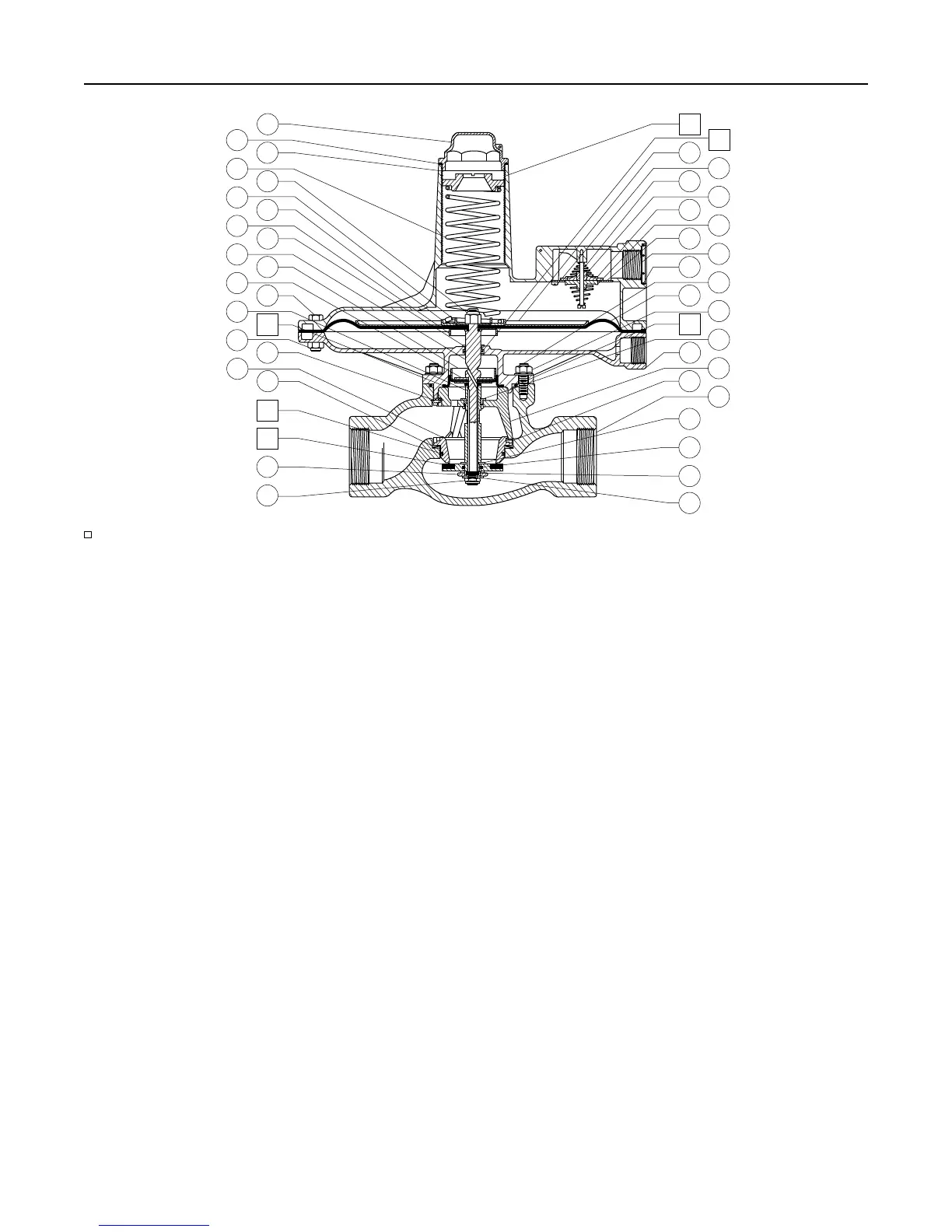

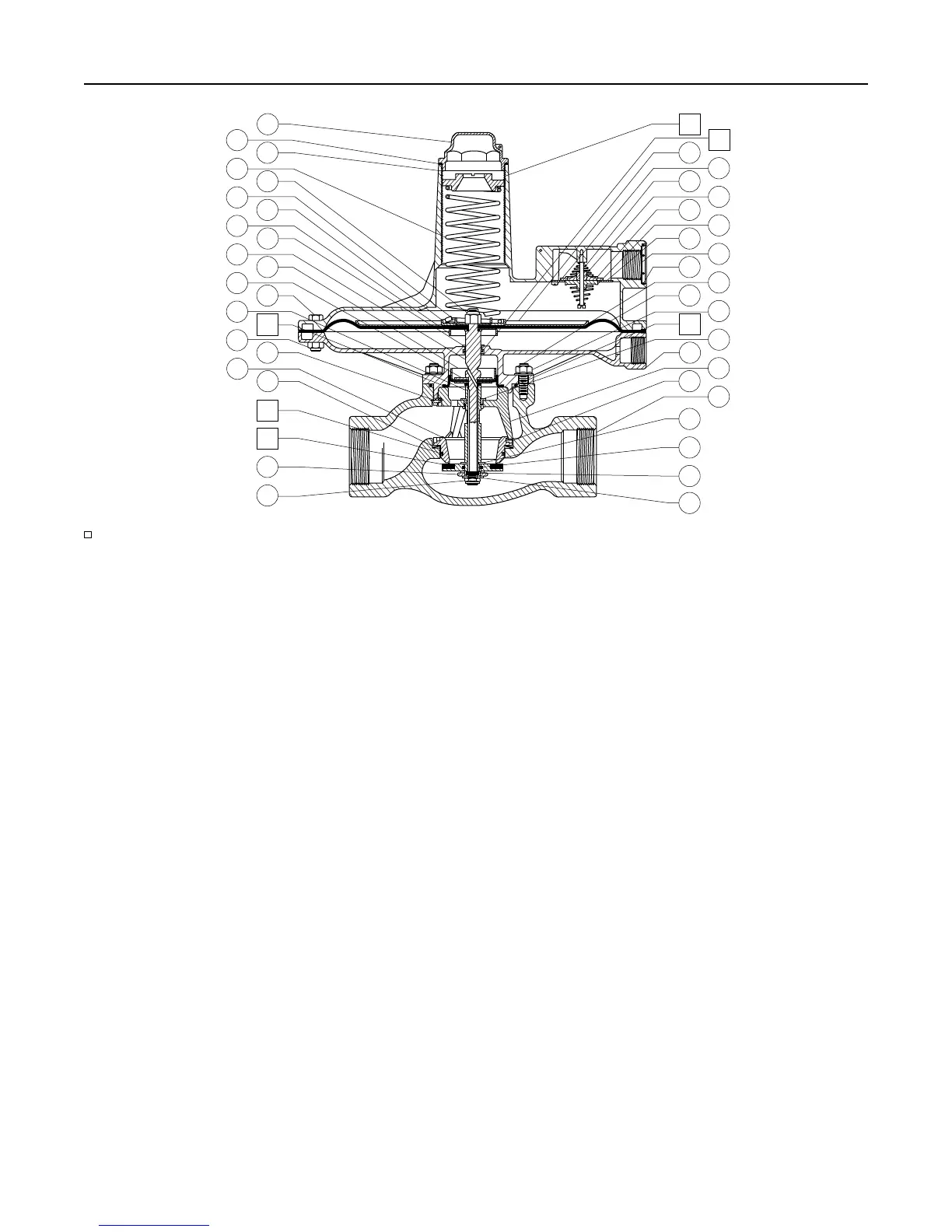

Figure 10. Type 133L Assembly

40A3066

Key Description Part Number

2* Orice, Aluminum 20A3046X012

3 Belleville Spring Washer, 17-4PH Stainless steel 10A3047X012

4* O-ring

Nitrile (NBR) 10A9339X012

Fluorocarbon (FKM)

(for Types 133L and 133H only) 10A9339X022

5* Cage/Pin Assembly, Aluminum/Steel

(including roll pins, key 5A) 20A3048X012

6* Bearing, Nylon (PA) 10A3049X012

7 Lower Casing

Types 133H, 133L and 133Z, Aluminum 40A3050X012

Type 133HP, Steel 32B3499X012

8 Spring Case

Type 133HP, Cast iron 2H140619012

Parts 8A through 8J are used on

Types 133H, 133L and 133Z only

8A Spring Case, Aluminum 4L142308032

8B Stabilizer Stem, 302 Stainless steel 1H976335022

8C Lower Stabilizer, Nylon (PA) 1H976406992

8D Upper Stabilizer, Polyethylene 1H976506992

8E Orice, Stainless steel T13609T0012

8F Screw, Steel (3 required) 1H976728982

8G Spring, 302 Stainless steel (2 required) 1H976837022

8H Screen, Stainless steel 1E564843122

8J Snap Ring, 302 Stainless steel 1E564937022

9 Closing Cap

Types 133H, 133L and 133Z, Aluminum 1L928308012

Type 133HP, Cast iron 00288819012

10* Closing Cap Gasket

Types 133H, 133L and 133Z, Neoprene (CR) 1N446206992

Type 133HP, Composition 1R742604022

Key Description Part Number

11 Adjusting Screw

Type 133H, Brass 1V9069X0012

Type 133L, Aluminum 1L928608012

Type 133Z, Brass 1K633714012

Type 133HP, Steel 1H139731012

12 Spring Steel

Type 133H

Zinc-plated steel

1.5 to 3 psig / 0.10 to 0.21 bar, Orange 1H975927032

2 to 5 psig / 0.14 to 0.34 bar, Yellow 10A9440X012

17-7 PH Stainless steel

5 to 10 psig / 0.34 to 0.69, Blue 1J146927142

Types 133L and 133H

(1)

Zinc-plated steel

2 to 4 in. w.c. / 5 to 10 mbar, Brown 1D892527022

3.5 to 6 in. w.c. / 9 to 15 mbar, Red 1D892627022

Plated steel

5 to 9 in. w.c. / 12 to 22 mbar, Black 1D892727012

8.5 to 18 in. w.c. / 21 to 45 mbar, White 1D893227032

14 to 28 in. w.c. / 35 to 70 mbar, Green 1D893327032

0.75 to 2 psig / 0.05 to 0.14 bar, Blue 1H975827032

Type 133Z (Extension spring, key 44, also required)

Zinc-plated steel

-1 to 1 in. w.c. / -2 to 2 mbar, see key 44

0 to 4 in. w.c. / 0 to 10 mbar, Brown 1D892527022

Type 133HP

17-7 PH Stainless steel

2 to 5 psig / 0.14 to 0.34 bar, Yellow 17B8632X012

302 Stainless steel

4.5 to 10 psig / 0.31 to 0.69 bar, Orange 17B8633X012

9

11

39

22

35

21

6

31

29

28

4

3

13

20

8A

14

7

32

15

8J

8E

5A

27

19

26

30

8D

8G

19

8F

5

24

34

33

8H

1

8C

8B

12

10

2

36

25

23

18

16

17

APPLY LUBRICANT (L) OR SEALANT (S)

(1)

1. Lubricant and sealant must be selected such that they meet the temperature requirements.

Loading...

Loading...