133 Series

5

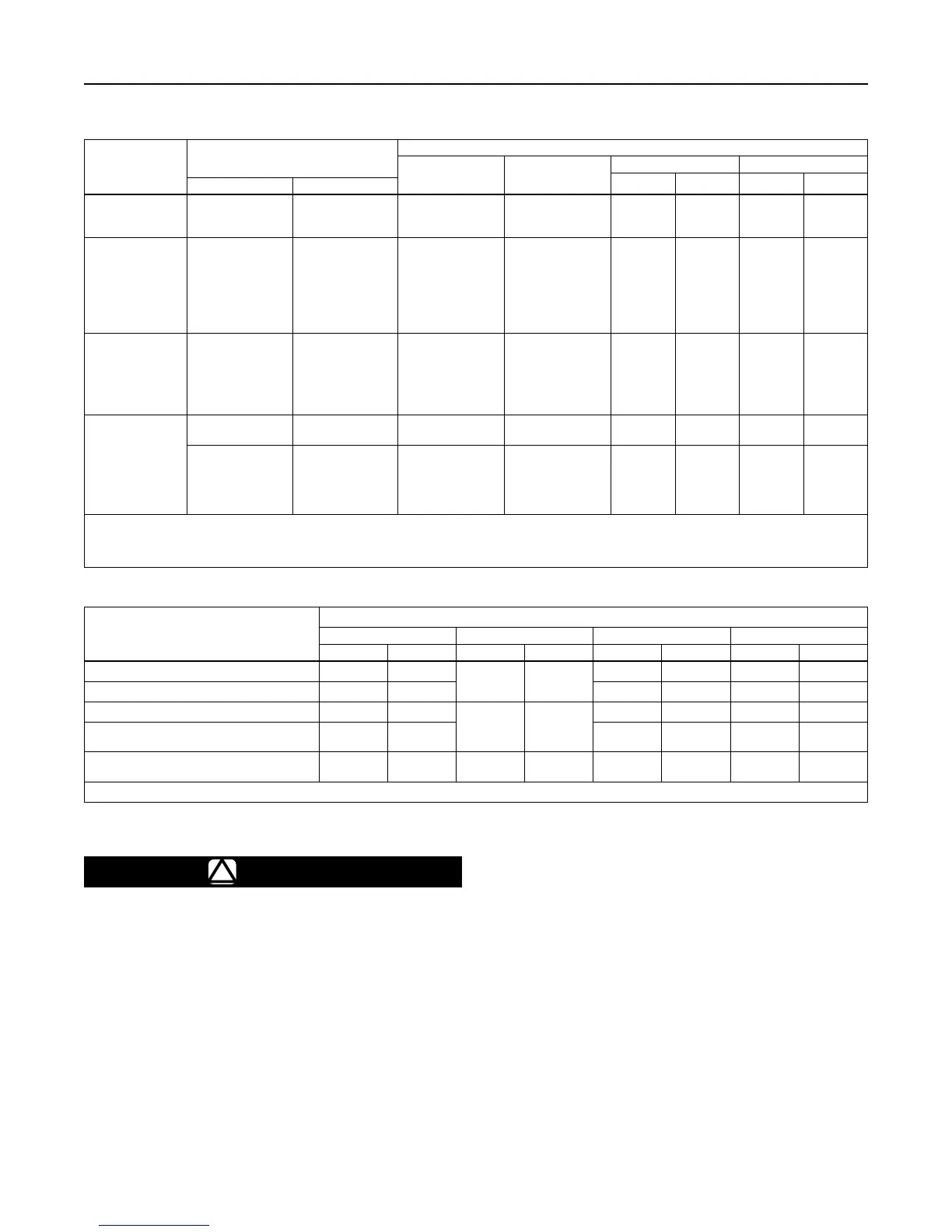

Table 1. 133 Series Outlet Pressure Ranges, Control Springs

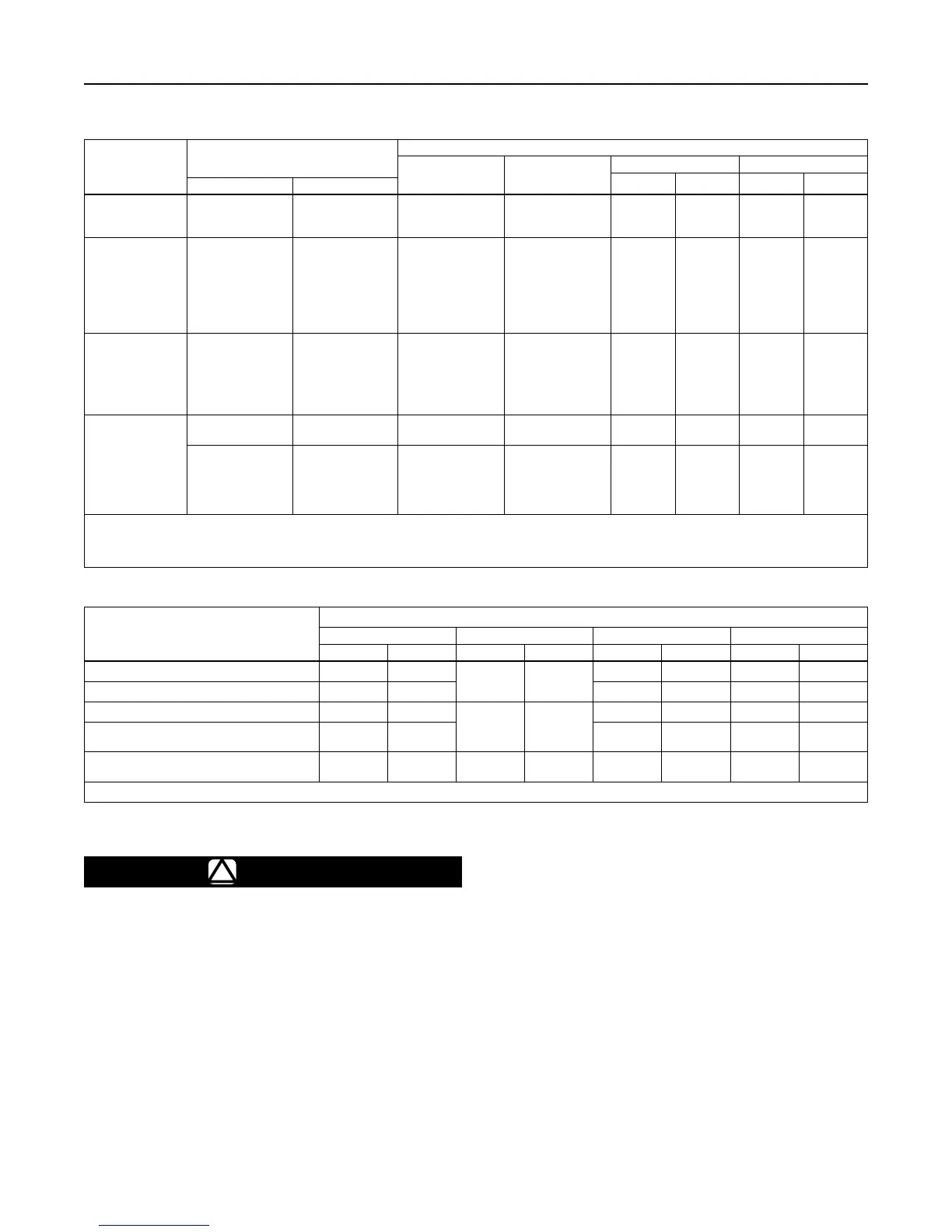

Table 2. Maximum Inlet and Outlet Pressures

TYPE

OUTLET PRESSURE RANGE

CONTROL SPRINGS

Part Number Color Code

Free Length Wire Diameter

In. mm In. mm

psig bar

133H

(1)

1.5 to 3

2 to 5

5 to 10

0.10 to 0.21

0.14 to 0.34

0.34 to 0.69

1H975927032

10A9440X012

1J146927142

Orange

Yellow

Blue

6.91

6.47

6.19

176

164

157

0.250

0.283

0.375

6.35

7.19

9.52

133HP

(1)

2 to 5

4.5 to 10

6 to 20

16 to 30

26 to 40

36 to 50

45 to 60

0.14 to 0.34

0.31 to 0.69

0.41 to 1.4

1.1 to 2.1

1.8 to 2.8

2.5 to 3.4

3.1 to 4.1

17B8632X012

17B8633X012

10C1238X012

10C1240X012

10C1241X012

10C1242X012

10C1243X012

Yellow

Orange

Silver

Red

Blue

Green

White

8.50

8.50

8.25

8.25

8.25

8.25

8.25

216

216

210

210

210

210

210

0.282

0.343

0.375

0.438

0.500

0.500

0.531

7.16

8.71

9.53

11.1

12.7

12.7

13.5

133L

(1)

and 133H

(2)

2 to 4 in. w.c.

3.5 to 6 in. w.c.

5 to 9 in. w.c.

8.5 to 18 in. w.c.

14 to 28 in. w.c.

0.75 to 2

5 to 10 mbar

9 to 15 mbar

12 to 22 mbar

21 to 45 mbar

35 to 70 mbar

0.05 to 0.14

1D892527022

1D892627022

1D892727012

1D893227032

1D893327032

1H975827032

Brown

Red

Black

White

Green

Blue

6.13

7.53

7.88

7.50

7.25

7.09

156

191

200

190

184

180

0.109

0.112

0.130

0.156

0.182

0.225

2.77

2.85

3.30

3.96

4.62

5.72

133Z

(1)

-1 to 1 in. w.c. -3 to 3 mbar

1K633427012

(Extension Spring)

Unpainted 2.00 50.8 0.075 1.91

0 to 4 in. w.c. 0 to 10 mbar

1K633427012

(Extension Spring)

and

1D892527022

(Compression Spring)

Unpainted

Brown

2.00

6.13

50.8

156

0.075

0.109

1.91

2.77

1. Pressure ranges shown are correct if the regulator is installed with the actuator portion above the body portion. If the regulator is installed with the actuator portion below the body, the

pressure ranges will be lowered by approximately 2 in. w.c. / 5 mbar for the Type 133L and by approximately 3 in. w.c. / 7 mbar for the Types 133H and 133Z.

2. If the 2 in. w.c. / 5 mbar to 2 psig / 0.14 bar springs (all 6 ranges) are used in the Type 133H, the pressure ranges will increase by approximately 1 in. w.c. / 2 mbar due to the weight of

the Type 133H parts (assuming that the actuator is installed above the body).

PRESSURES

TYPE NUMBER

133H 133HP 133L 133Z

psig bar psig bar psig bar psig bar

Maximum Operating Inlet Pressure 60 4.1

150 10.5

60 4.1 20 1.4

Maximum Emergency Inlet Pressure 125 8.6 125 8.6 125 8.6

Maximum Operating Outlet Pressure

(1)

10 0.69

Setpoint

plus 40

Setpoint

plus 2.8

2 0.14 4 in. w.c. 10 mbar

Maximum Outlet Pressure Over

Outlet Pressure Setting

3 0.21 3 0.21 3 0.21

Maximum Emergency Outlet

(Casing) Pressure

15 1.0 150 10.5 15 1.0 15 1.0

1. With highest spring range available only.

Startup

!

WARNING

If the downstream system is already

pressured by another regulator or by a

manual bypass, then extra precautions

must be taken when placing the 133 Series

in service. The outlet of the regulator must

never be subjected to pressure higher

than the inlet pressure or the balancing

diaphragm may be damaged. Also, the

control line pressure must never exceed

the set point dictated by the spring setting

by more than 3 psig / 0.21 bar or the

valve seat or diaphragm plates can be

damaged. The procedure used in putting

the regulator in service must be planned

accordingly. Pressure gauges should

always be used to monitor downstream

and control line pressures during startup.

If the downstream system is not pressured by

another regulator or by manual bypass, use the

following procedure:

1. Check to see that all appliances are turned off.

2. Slowly open the upstream shutoff valve.

3. Slowly open the downstream shutoff valve.

4. Check all connections for leaks.

5. Make nal control spring adjustments according to

the adjustment procedures.

Loading...

Loading...