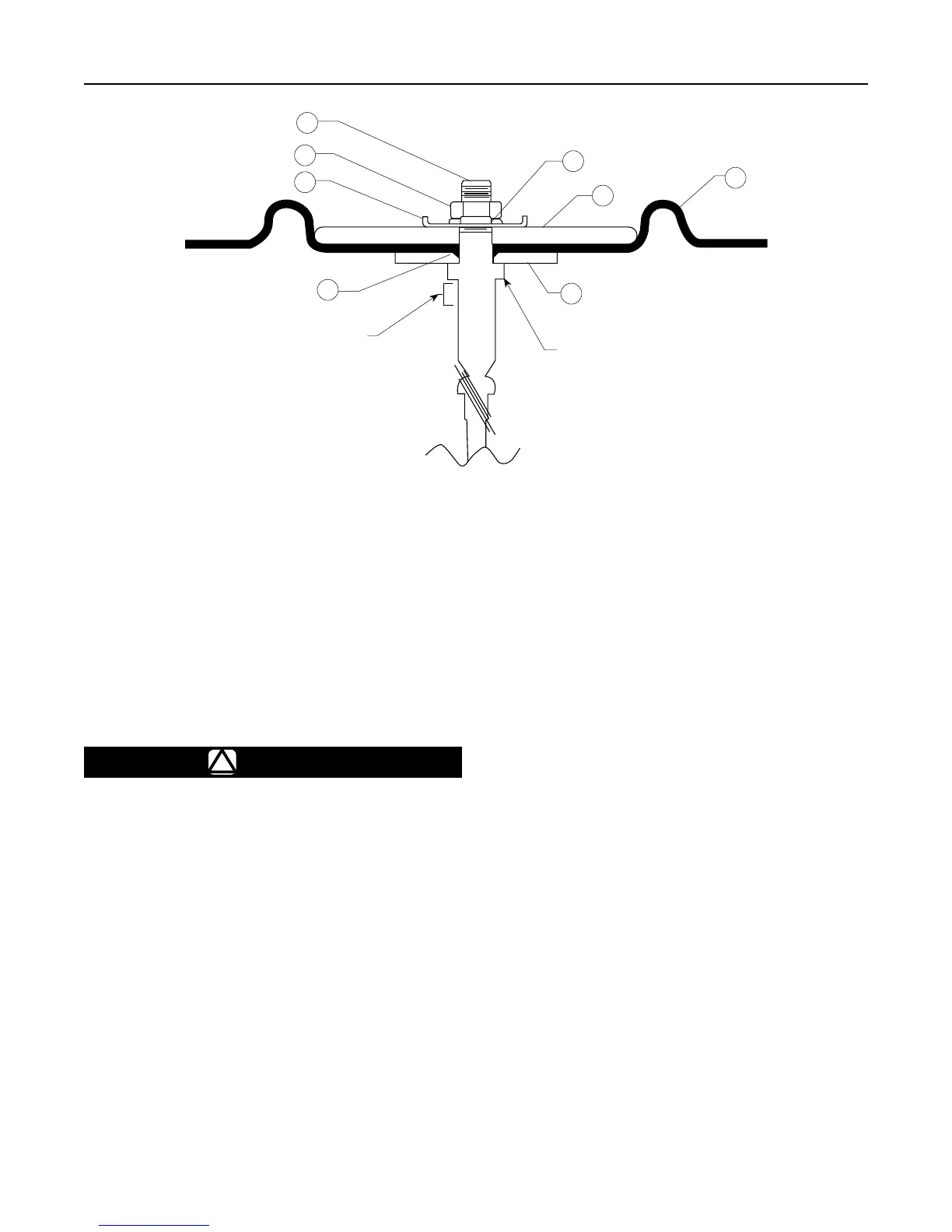

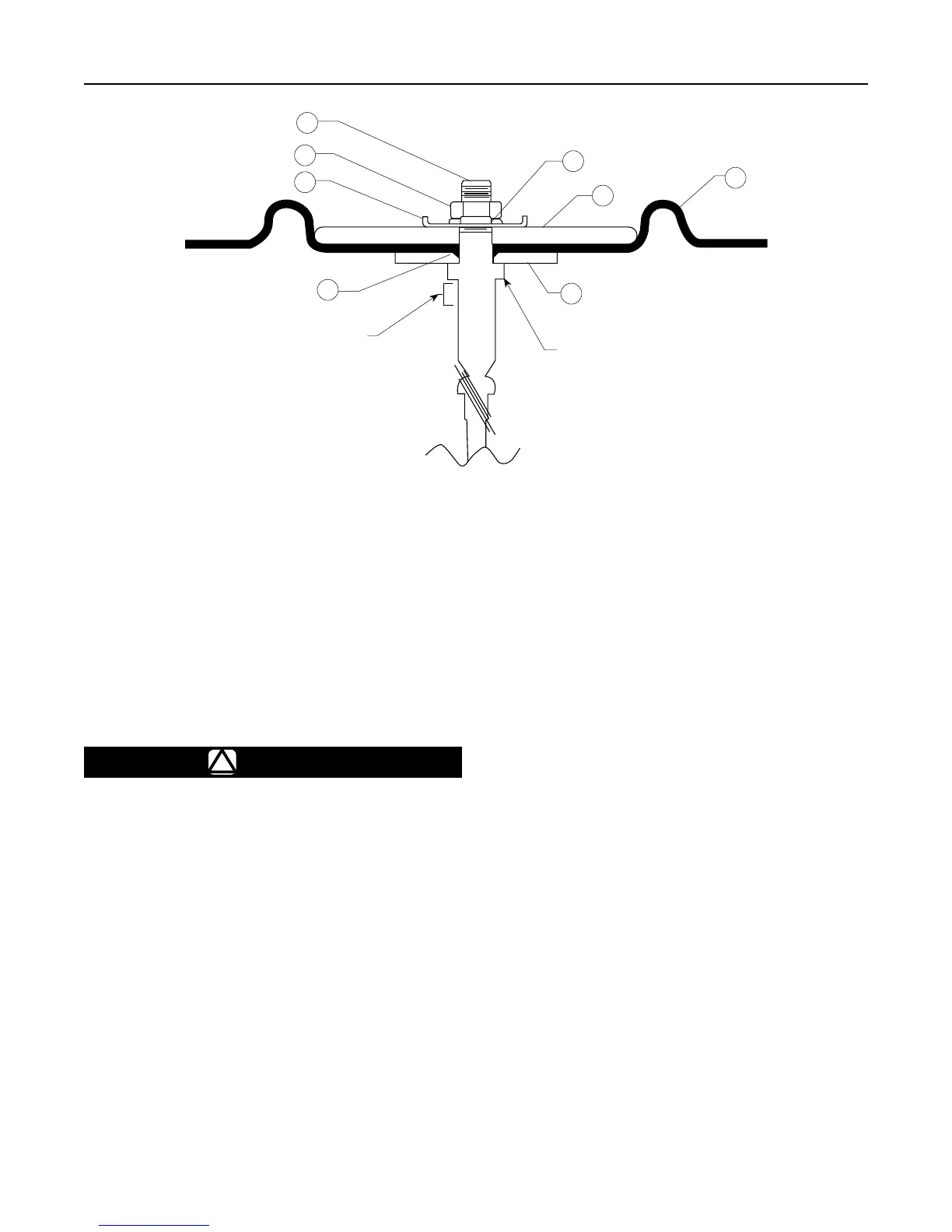

133 Series

9

18

20

13

61

PROTECT THE

O-RING

SURFACE

FROM DAMAGE

3/4 in. / 19 mm

STEM HEX

16

58

14

15

A7007

Figure 7. Stem and Diaphragm Assembly

the stem (key 18). Lift off the orice (key 2) and

replace the valve disk and orice if necessary.

5. Loosen the set screws (key 39) in the cage (key 5)

and remove the roll pin (key 27) from the stem

(key 18). Remove the cage and stem sleeve

(key 25), the sealing washer (key 17) under

the balancing diaphragm (key 22), at washers

(key 23), balancing diaphragm and balancing

diaphragm plate (key 21). Replace the sealing

washer and balancing diaphragm if necessary.

!

WARNING

• To avoid personal injury due to the

sudden uncontrolled movement of

parts, do not loosen the diaphragm

casing cap screws (keys 35 and 36)

when the control spring (key 12) has

spring force applied to it.

• Release the spring compression as

described in step 6 below.

6. To inspect or replace the upper stem seal O-ring

(key 19) or main diaphragm (key 15), remove the

closing cap (key 9) and inspect the closing cap

gasket (key 10). Release the spring compression

completely by loosening the hex nut (key 59) and

turning the adjusting screw (key 11) counterclockwise.

7. Remove the six cap screws (key 62) from the

spring case (key 8). Lift off the spring case, upper

spring seat (key 41) and spring (key 12). Remove

the diaphragm casing cap screws and hex nuts

(keys 35 and 36) and lift off the upper diaphragm

casing (key 52). Remove the cap screws (key 55)

and mounting bracket (key 56). Inspect the two

mounting bracket gaskets (key 57) and replace

if necessary.

8. Remove the hex nut (key 20), lock washer (key 58)

and spring seat (key 13) from the stem (key 18).

9. Remove the diaphragm plate (key 14), diaphragm

(key 15), diaphragm washer O-ring (key 61)

and sealing diaphragm plate (key 16). Replace

the diaphragm and diaphragm washer O-ring

if necessary.

10. Remove the cap screws (key 53) and lift the

lower diaphragm casing (key 7) off the casing

adaptor (key 60). If necessary, replace the

bearing (key 6) and upper stem seal O-ring

(key 19). Before reassembling, coat the O-ring

with a O-ring sealant and lubricant.

Reassembly

When reassembling, observe the following steps

and cautions. During reassembly, check all O-rings

to be certain they are in good condition and replace

if necessary. Coat O-rings (keys 4, 19 and 32) with

Multi-Purpose Polytetrauoroethylene (PTFE) lubricant

or an equivalent elastomer sealant and lubricant.

All key numbers refer to Figures 7, 8, 9 and 14, except

where indicated.

Loading...

Loading...