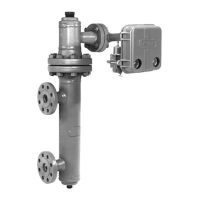

Type 2500

11

Controller/Transmitter Output Connection

As shown in figure 11, the output pressure connection

is on the back of the controller/transmitter case. After

connecting the output pressure line, turn on the supply

pressure, adjust the filter/regulator to the appropriate

supply pressure required for the controller/transmitter

and check all connections for leaks.

Prestartup Checks

Adjustments are shown in figure 12 unless otherwise

indicated. Open-loop conditions must exist when per-

forming the prestartup checks. To obtain open-loop

conditions:

make sure there is no process flow through the

final control element, or

disconnect the controller/transmitter output signal

line and connect it to a pressure gauge.

During prestartup, the displacer must be positioned

from its maximum to its minimum range of operation.

Provide a means to change the process variable (the

process level or interface). If the process variable can-

not be varied sufficiently, use the precalibration proce-

dures in the Calibration section to simulate the pro-

cess variable changes required for these checks.

Make sure the RAISE LEVEL dial on the controller is

mounted with the correct side facing out. The dial is

marked on both sides with an arrow. The arrow points

to the left on one side and to the right on the other.

When the sensor is mounted to the left of the control-

ler/transmitter, the arrow on the raise level dial should

point to the left, as shown in figure 12. If the sensor is

to the right, the arrow should point to the right. If nec-

essary, remove the two mounting screws, turn the dial

over so the arrow points correctly, and reinstall the

mounting screws. The level directions shown on the

dial will be correct for both direct-acting and reverse-

acting controllers. For a transmitter, use the same side

of the ZERO ADJUSTMENT dial for both right- and

left-hand sensor mountings.

On a controller or transmitter with an optional mechan-

ical indicator assembly, the travel indicator plate is

also marked with an arrow on both sides. If the sensor

is to the left of the controller/transmitter, the arrow on

the plate should point to the left. If the sensor is to the

right, the arrow should point to the right. If necessary,

reinstall the plate so that the arrow points in the cor-

rect direction.

Set the PROPORTIONAL BAND control on a Type

2500 or 2500S controller, or the SPECIFIC GRAVITY

control on a Type 2500T transmitter, as follows:

Sensor with Both Standard Torque Tube and

Standard Volume Displacer—If the torque tube is

standard and the displacer volume is close to that

listed in table 2, use figure 13 to find the PROPOR-

TIONAL BAND or SPECIFIC GRAVITY setting. Lo-

cate the specific gravity of the process fluid on fluid

level applications, or the difference between minimum

and maximum specific gravity on interface level or

density applications, on the vertical axis of the chart.

From this location, trace horizontally to the curve with

the desired percentage of displacer used, then trace

vertically up or down to determine the proper dial set-

ting on the horizontal axis.

Sensor with Nonstandard Torque Tube and/

or Displacer with Other than Standard Volume—If

the construction does not have a standard wall torque

tube or has a displacer volume that deviates signifi-

cantly from the volume listed in table 2, or both, the

PROPORTIONAL BAND or SPECIFIC GRAVITY dial

setting does not necessarily indicate the actual propor-

tional band or specific gravity. To determine the cor-

rect dial setting, solve the following equation:

Corrected

Dial Setting

Required

(

L

100

)(SP GR)

V

a

V

r

(X)

where:

L

= percentage of displacer length desired for full

output pressure change (e.g., if 80% of dis-

placer is used, L = 80)

SP GR = specific gravity of

the process fluid (for inter

-

face level control, use the difference be-

tween the specific gravity of the two fluids;

for specific gravity control, use the differ-

ence between the upper and lower range

limits of specific gravity).

V

a

= actual displacer volume, cubic inches listed

on the sensor nameplate.

V

r

= standard displacer volume, cubic inches, from

table 2.

X = torque tube factor (1.0 for standard torque

tubes, 2.0 for thin-wall torque tubes, or 0.5

for heavy-wall torque tubes).

Loading...

Loading...