Instruction Manual

D100307X012

657 Size 80 and 100 Actuators

December 2010

2

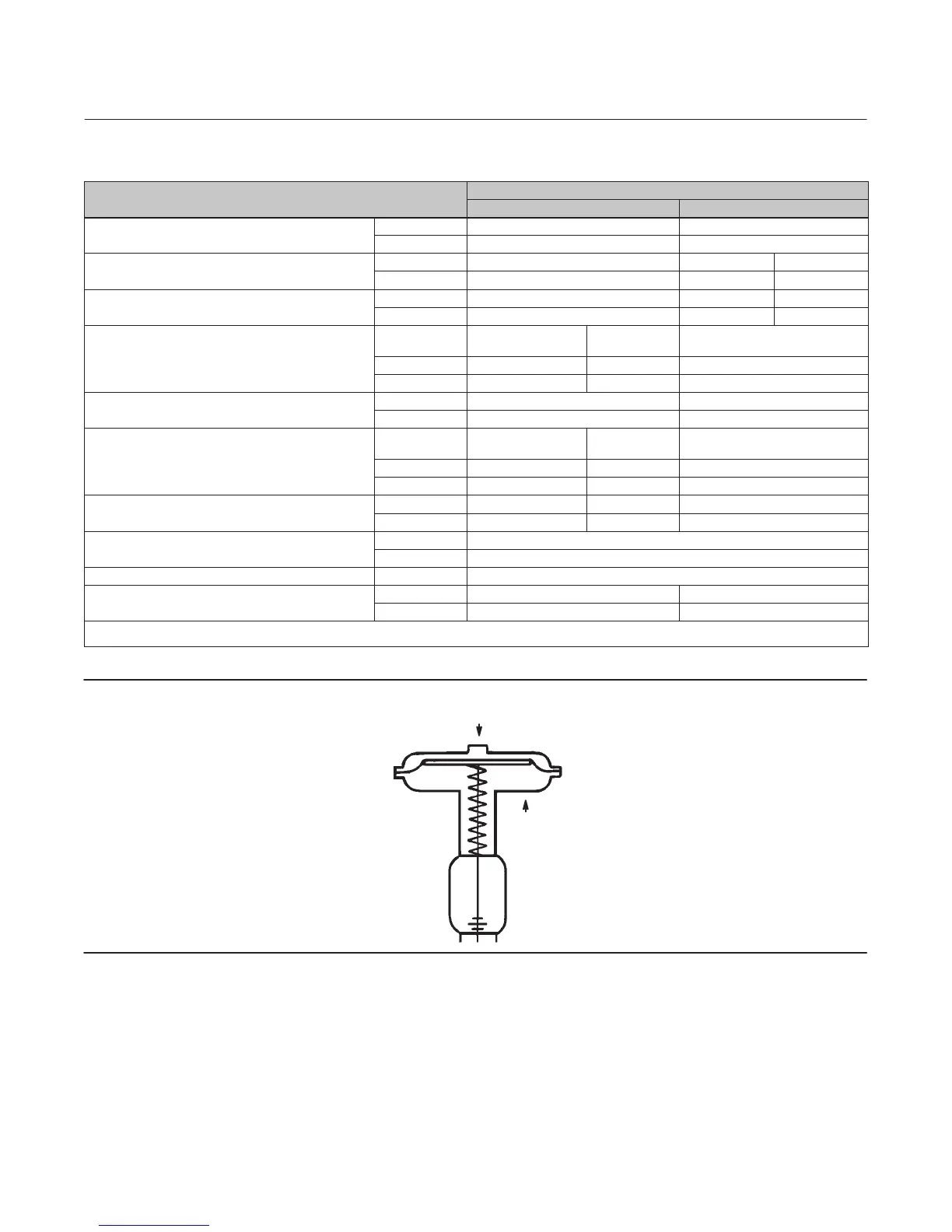

Table 1. Specifications

SPECIFICATIONS

ACTUATOR SIZE

80 100

Nominal Effective Diaphragm Area

cm

2

1761 2902

inch

2

273 450

Yoke Boss Diameters

mm 127 127 178

inch 5 5H

(1)

7

Acceptable Valve Stem Diameters

mm 25.4 or 31.8 31.8 50.8

inch 1 or 1‐1/4 1‐1/4 2

Maximum Allowable Output Thrust

Standard Cast Iron

Construction

All Steel

Construction

N 62942 88075 200170

lb 14150 19800 45000

Maximum Travel

mm 76 102

inch 3 4

Maximum Casing Pressure for Actuator Sizing

Standard Cast Iron

Construction

All Steel

Construction

bar 3.4 4.9 6.9

psig 50 70 100

Maximum Diaphragm Casing Pressure

(2)

bar 4.1 5.5 7.9

psig 60 80 115

Material Temperature Capabilities

_C -40 to 82

_F -40 to 180

Pressure Connections 1/4 NPT internal

Approximate Weights Without Handwheel

kg 234 346

lb 515 762

1. Heavy actuator‐to‐bonnet bolting.

2. This maximum casing pressure is not to be used for normal operating pressure.

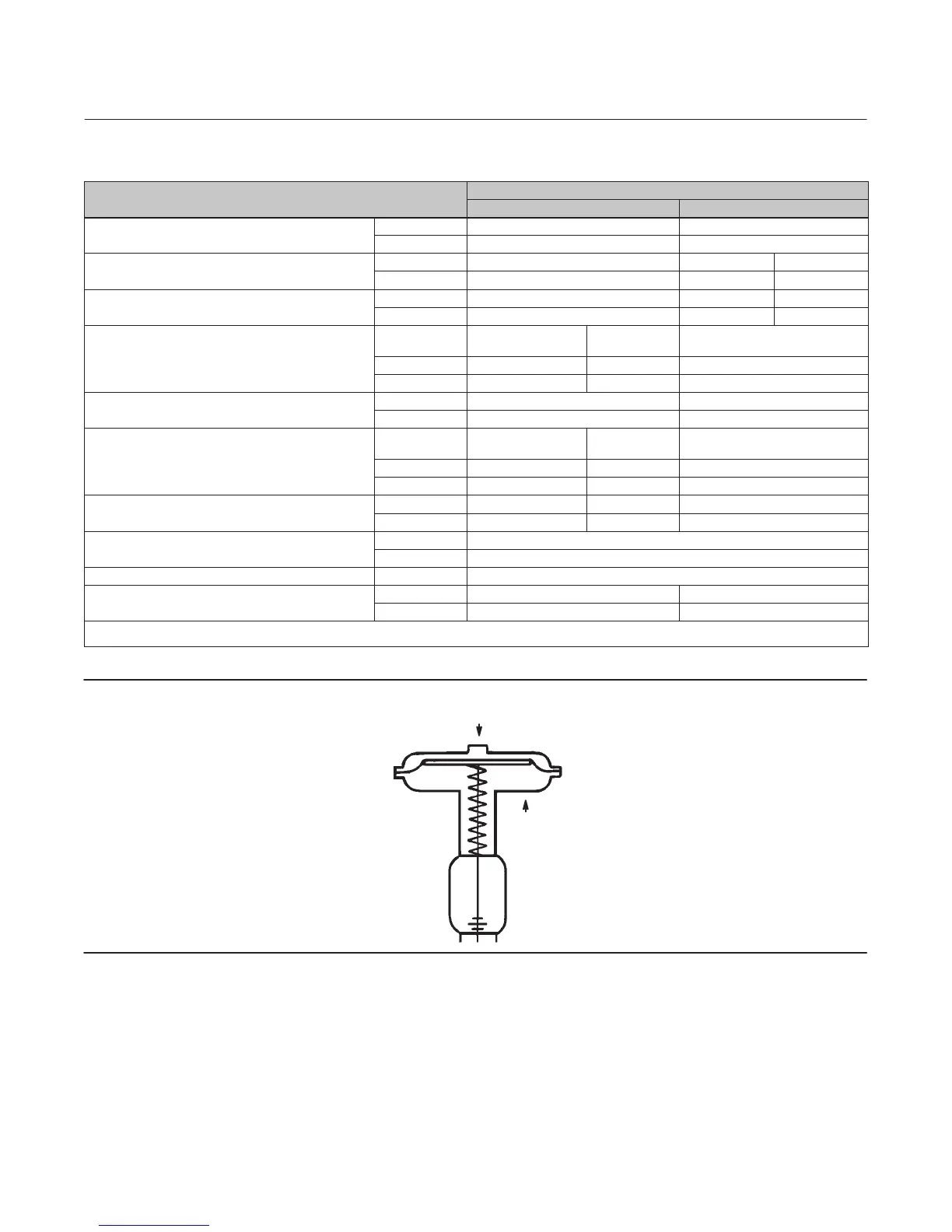

Figure 2. Schematic Representation of Fisher 657 Actuator

SPRING LIFTS

AIR PUSHES STEM DOWN

AF3833‐A

A0792‐2

Description

The 657 actuator (figure 1) is a direct‐acting, spring‐opposed diaphragm actuator used for automatic operation of

control valves. The actuator positions the valve plug in response to varying pneumatic loading pressure on the

diaphragm. Figure 2 shows the operation of these actuators.

A 657 actuator can be furnished with either a top‐mounted or side‐mounted (size 80 only) handwheel assembly. A

top‐mounted handwheel assembly is normally used as an adjustable‐up travel stop. The size 100 top‐mounted

Loading...

Loading...