EH Valves (NPS 8 through 14)

Instruction Manual

April 2009

3

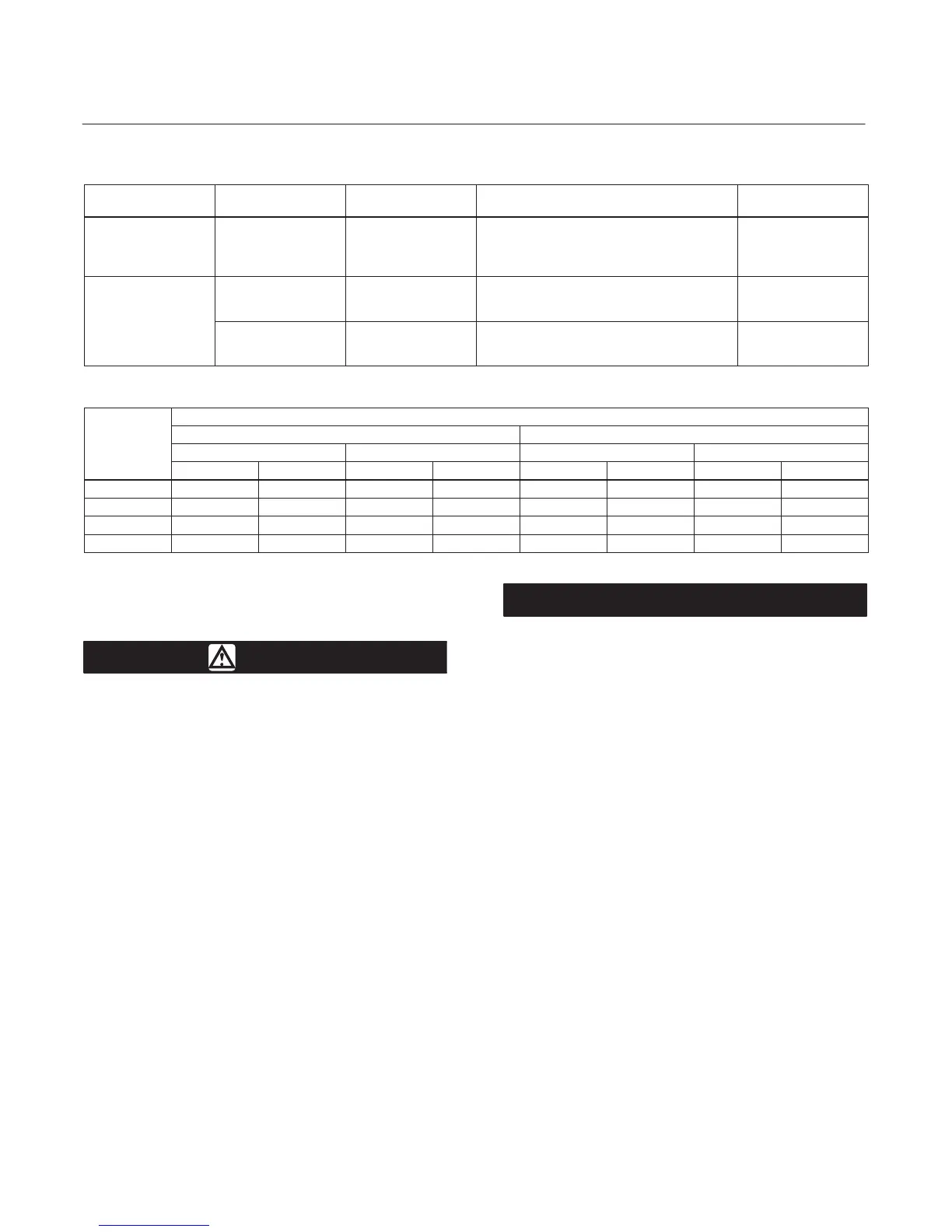

Table 3. Additional Shutoff Classification

VALVE DESIGN

(PRESSURE RATING)

VALVE SIZE, NPS

PORT DIAMETER,

INCHES

CAGE STYLE

ANSI/FCI LEAKAGE

CLASS

EHD

(CL500)

8

10

7

Equal Percentage

Modified Equal Percentage

Linear (std. cage)

Linear (Whisper III, A1, B3, C3)

V with

optional Bore seal trim

EHD

(CL2500)

8

10

5.375

Equal Percentage, Modified Equal Percentage,

Linear (std. cage),

Linear (Whisper III, A1, B3, C3, D3)

V with

optional Bore seal trim)

12

14

7

Equal Percentage, Modified Equal Percentage,

Linear (std. cage),

Linear (Whisper III, A1, B3, C3, D3)

V with

optional Bore seal trim)

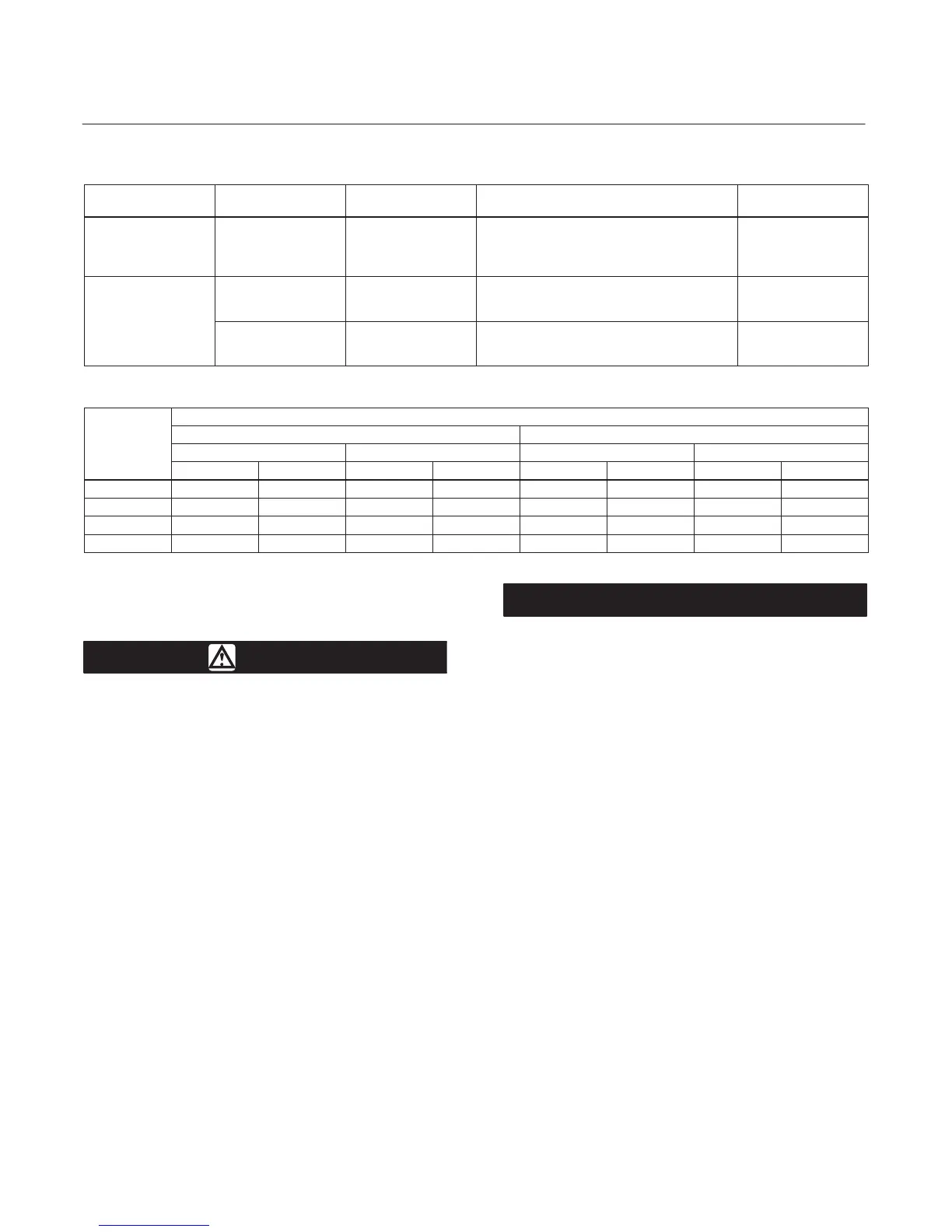

Table 4. Approximate Weights (Valve Body and Bonnet Assemblies)

VALVE

SIZE,

NPS

WEIGHTS

CL1500 CL2500

Buttwelding Ends Flanged Buttwelding Ends Flanged

Kilograms Pounds Kilograms Pounds Kilograms Pounds Kilograms Pounds

8 1400 3100 1700 3700 1900 4100 2200 4700

10 1500 3300 1900 4100 2000 4400 - - - - - -

12 3400 7300 3900 8600 3400 7600 - - - - - -

14 3400 7300 - - - - - - 3400 7600 - - - - - -

Installation

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any installation operations

to avoid personal injury.

To avoid personal injury or property

damage resulting from the sudden

release of pressure, do not install the

valve assembly where service

conditions could exceed the limits

given in this manual or on the

appropriate nameplates. Use

pressure-relieving devices as required

by government or accepted industry

codes and good engineering practices.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

CAUTION

The valve configuration and

construction materials were selected

to meet particular pressure,

temperature, pressure drop, and

controlled fluid conditions. Because

some body/trim material combinations

are limited in their pressure drop and

temperature range capabilities, do not

apply any other conditions to the valve

without first contacting your Emerson

Process Management sales office.

If hoisting the valve, use a nylon sling

to protect the painted surfaces.

Carefully position the sling to prevent

damage to the actuator tubing or any

accessories. Also, take precautions to

prevent personnel from being injured

in case the hoist or rigging slips

unexpectedly. Refer to table 4 for valve

assembly weights and the appropriate

actuator instruction manual for

actuator assembly weights. Be sure to

use adequately sized hoists and

chains or slings to handle the valve

and actuator assembly.

1. Before installing the valve, inspect it to ensure

that the valve body cavity is free of foreign material.

Loading...

Loading...