Initial Setup and Calibration

November 1999

3-3

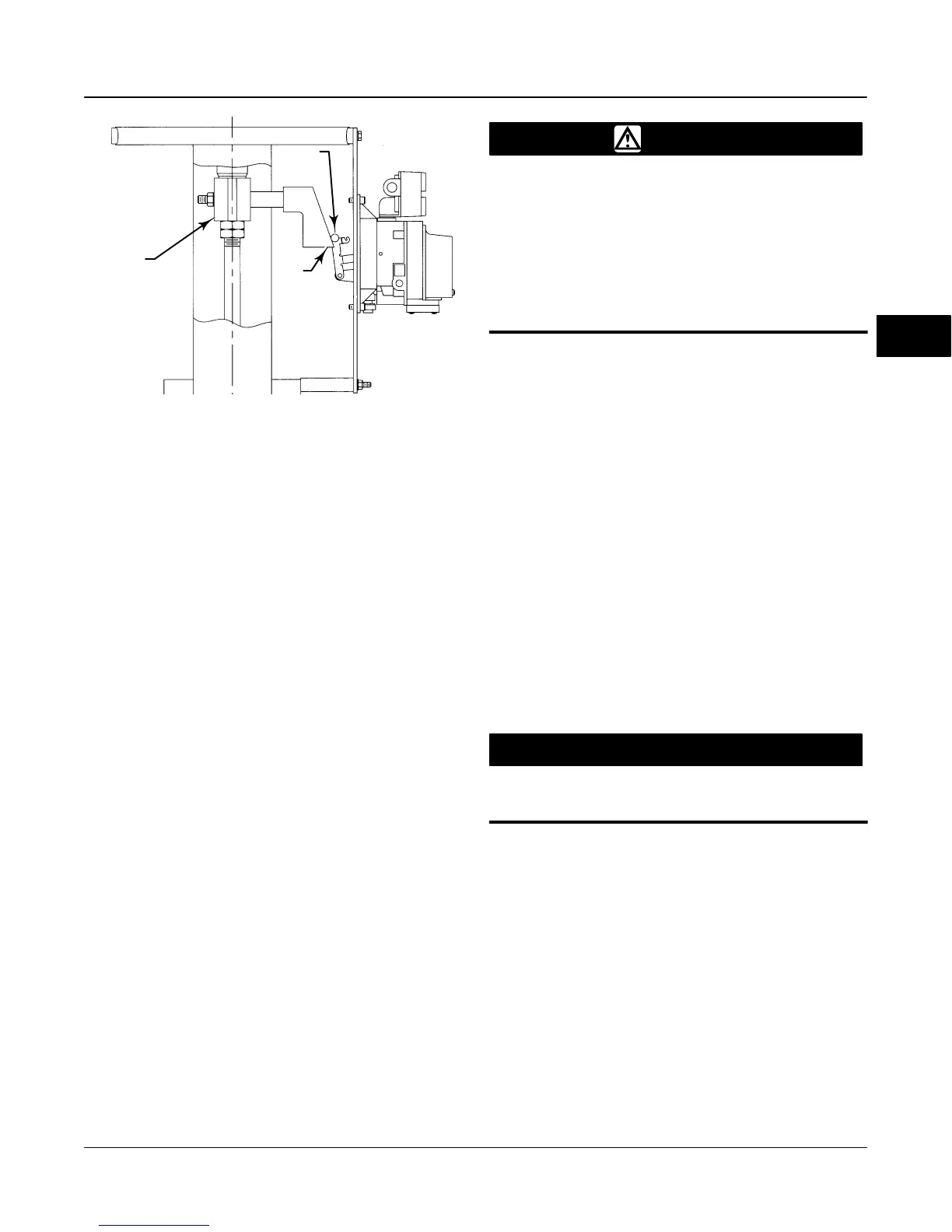

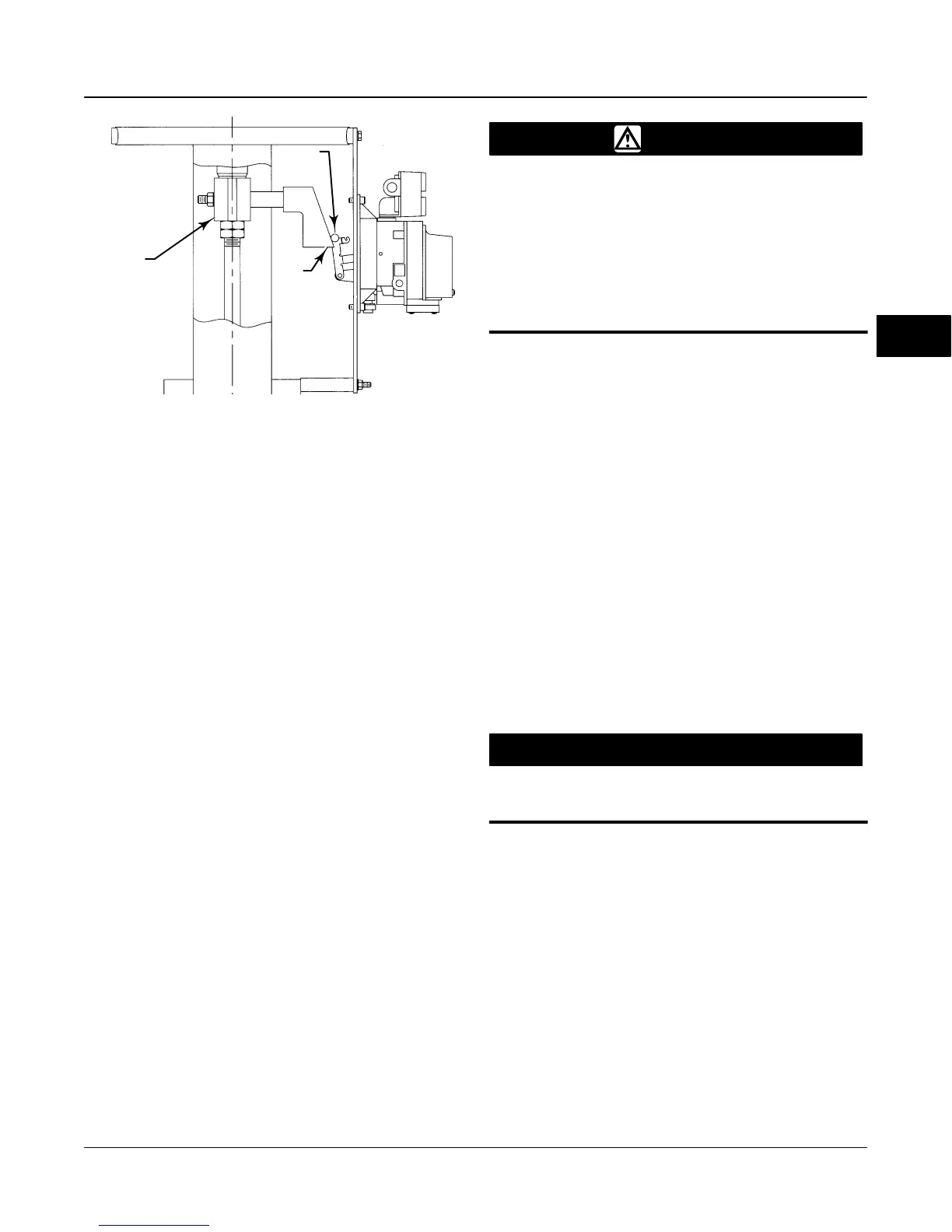

Figure 3-3. Feedback Connection for

Model 471 Sliding-Stem Actuator

CAM

ROLLER

27B6708-B

E0032 / IL

STEM

CONNECTOR

After the Setup Wizard completes the setup, press OK

to return to the Auto Setup menu. Select Auto Calib

Travel to automatically calibrate the instrument travel.

Follow the prompts on the HART Communicator

display. The calibration procedure uses the valve and

actuator stops as the 0% and 100% calibration points.

For additional information, refer to Auto Calibrate

Travel in this section.

Other Mountings

If the actuator on which the instrument is mounted is

not listed by the Setup Wizard, specify OTHER as the

actuator manufacturer or actuator type. You are then

prompted for setup parameters such as:

D Actuator Type (single-acting or double-acting)

D Valve Style (rotary or sliding-stem)

D Feedback Connection (Rotary - All, SStem -

Standard, SStem - Roller). For rotary valves, enter

Rotary - All. For sliding-stem valves, if the feedback

linkage consists of a connector arm, adjustment arm,

and feedback arm (as shown in figure 3-4), enter

SStem - Standard. If the feedback linkage consists of

a roller that follows a cam (as shown in figure 3-3),

enter SStem - Roller.

D On Loss of Instrument Signal, Valve (opens

or closes) This identifies whether the valve is fully

open or fully closed when the input is 0%. If you are

unsure how to set this parameter, disconnect the

current source to the instrument. (With direct acting

digital valve controllers, disconnecting the current

source is the same as setting the output pressure to

zero.)

WARNING

If you answer YES to the prompt for

permission to move the valve, the in-

strument will move the valve through

a significant portion of its travel

range. To avoid personal injury and

property damage caused by the re-

lease of pressure or process fluid,

provide some temporary means of

control for the process.

D Travel Sensor Motion (increasing air pressure

causes the travel sensor shaft to rotate clockwise or

counterclockwise), The Setup Wizard asks if it can

move the valve to determine travel sensor motion. If

you answer yes, the instrument will stroke the valve

the full travel span to determine travel sensor motion.

If you answer No, then you must specify the rotation

for increasing air pressure: clockwise or counterclock-

wise. Determine rotation by viewing the end of the

travel sensor shaft, as shown in figure 3-4. If

increasing air pressure to the actuator causes the

shaft to turn clockwise, enter CW (clockwise). If it

causes the shaft to turn counterclockwise, enter CCW

(counterclockwise).

D Instrument Supply Pressure Range. This

adjusts the range of the instrument pressure sensor.

Supply Pressure is configured in pressure units of psi,

bar, or kPa. Select a supply pressure range that

includes the instrument supply pressure.

CAUTION

Changes to the tuning set can result in

valve/actuator instability.

D Tuning Set There are eleven tuning sets to

choose from. Each tuning set provides preselected

values for the digital valve controller gain and rate

settings. Typically, tuning set C provides the slowest

response and M provides the fastest response. For

smaller actuators, use tuning set C or D. For larger

actuators , use tuning set F or G.

After the Setup Wizard completes the setup, press OK

to return to the Auto Setup menu. Select Auto Calib

Travel to automatically calibrate the instrument travel.

Follow the prompts on the HART Communicator

display. The calibration procedure uses the valve and

actuator stops as the 0% and 100% calibration points.

For additional information, refer to Auto Calibrate

Travel in this section.

3

Loading...

Loading...