We reserve the right to change designs and technical specifications of our products.

Manual ENA 7-30

2120

ENG

18

Next

maintenance

Next maintenance

due

A

• Maintenance date

reached

• Carry out maintenance

and enter „Maintenance

done“ (Service menu)

19

TP motor Motor protection

signal (bimetal

contact of pump) is

active (open)

A

• Pump overheated • Check temperatures

• Check free running

pump

20

Voltage

sensor

Sensor voltage too

low

B

• Printed circuit board

defective

• Replace control unit

21

No date/time RTC has no valid time

information

A

• Time setting has got

lost aer prolonged

disconnection from

power supply

• Enter time and date

again

22

Flash error Read error Flash

B

• Hardware/soware

problem

• Get in contact with

service department

23

Flash error Write error Flash

B

• Hardware/soware

problem

• Get in contact with

service department

24

Flash error Reprogramming error

Flash

B

• Hardware/soware

problem

• Get in contact with

service department

25

Gas sensor

defective

Gas sensor defective

A

• Malfunctions in

measuring signal,

possible faulty cable

connection to SCU

• Check connection to

controller, Exchange

sensor if necessary

26

Gas sensor,

undervoltage

Signal during

Measurement <4mA

A

• Sensor not connected,

cable damage

27

Gas sensor,

overvoltage

Signal during

Measurement >20mA

A

• Short-circuit in cable,

signal too large

• Test cable connections,

test vent device, if

necessary clean the filters

28

Recurring

indication of

gas value “0”

several successive

small gas values

during measurement

A

• Vent blocked/not

working correctly

• Check and clean vent

device

A: Necessary, reset possible within normal use (control restarts aer resetting).

B: No duty, automatic reset within normal use.

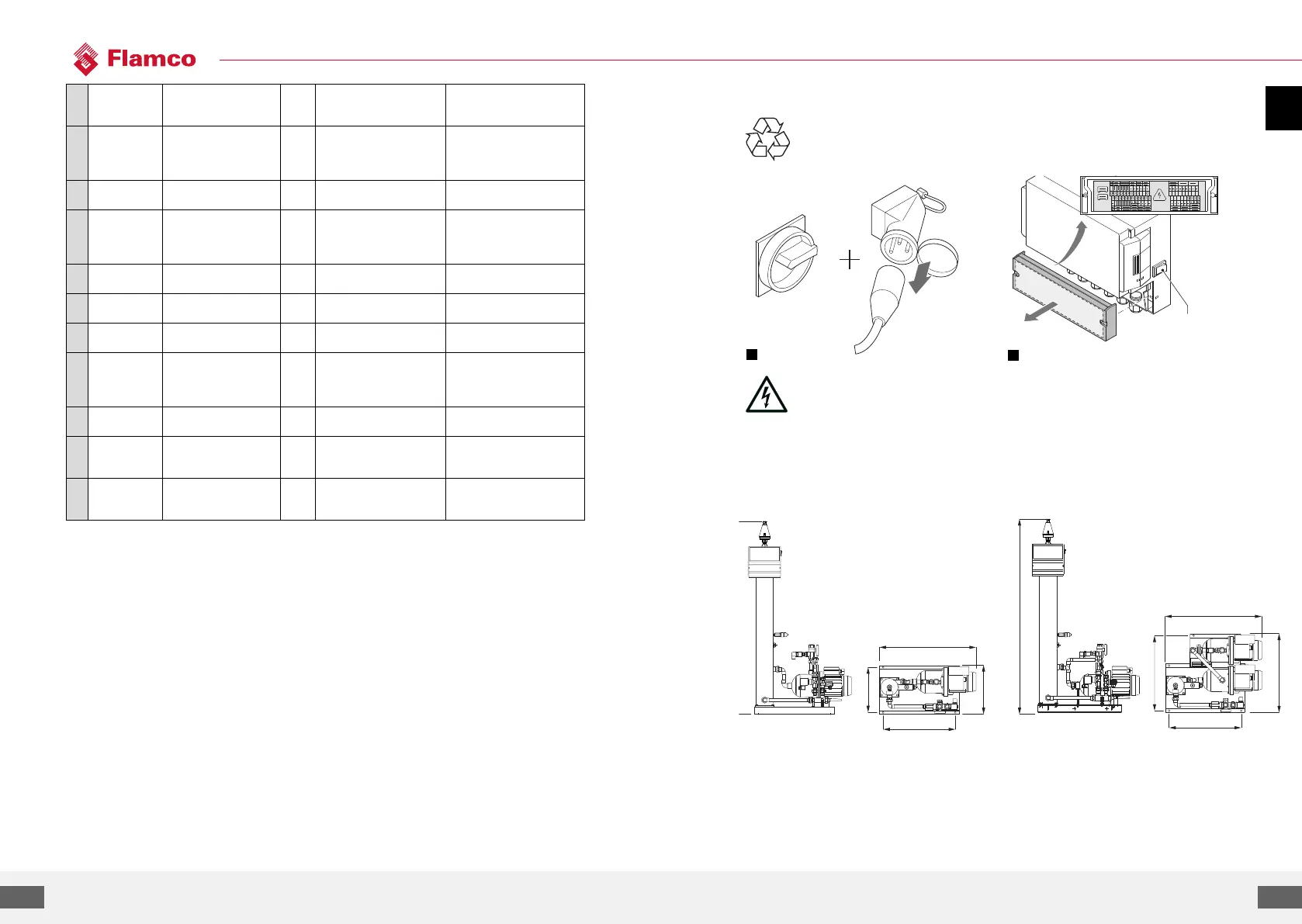

8. Disposal

Comply with local legislations.

IŠJUNGTA

OFF

• Make sure the system power switch

is OFF.

• Disconnect the power supply.

• Make sure the main power switch is OFF.

• Drain the water.

9. Technical specification

ENA 7

ENA 10

ENA 20

ENA 30

H

W

W

D

M1

M2

M1

M2

Loading...

Loading...