7

Remote IR Monitoring

While visible light cameras might be

used in such an application, there often

is a line-of-sight problem where many

of the barrels cannot be seen, even with

multiple cameras positioned throughout

the storage area. In addition, smoke or

ames would have to be present before

a visible light camera could detect a

problem. This might be too late for

preventative measures to be taken.

In contrast, stand-alone IR cameras

monitoring the facility can detect a

temperature rise within their FOV before

re occurs (Figures 2a and 2b).

Depending on the camera manufacturer,

several monitoring options are available.

For instance, the FLIR A320 camera

allows a threshold temperature value to

be set internally for alarm purposes. In

addition, the camera’s logic and clock

functions can be congured so that a rise

in temperature must be maintained for a

certain period of time before an alarm is

sent. This allows the system to ignore a

temporary temperature rise in a camera’s

FOV caused by a forklift entering the area

to add or remove barrels. Furthermore,

a hysteresis function can also be used to

prevent an alarm from turning o until

the detected temperature falls well below

the setpoint (Figure 3).

Cameras with a digital I/O interface

typically provide an OFF/ON type of

output for alarm purposes. The digital

I/O output is either o or on; when on, it

is typically a DC voltage or current. For

example, the digital I/O output from a

FLIR A320 camera is 10–30VDC for loads

of 100mA or less. Typically, the digital

I/O output is sent to a PLC (Programble

Logic Controller) that controls the portion

of an alarm system associated with the

monitored area.

A good way to set up the alarm system

is to have all cameras congured so they

have a high level digital output when the

temperature is below the alarm condition

that holds a PLC in its non-alarm state.

When the alarm setpoint temperature is

detected, the camera’s digital I/O output

goes low (typically zero volts) after an

appropriate time delay, causing the PLC

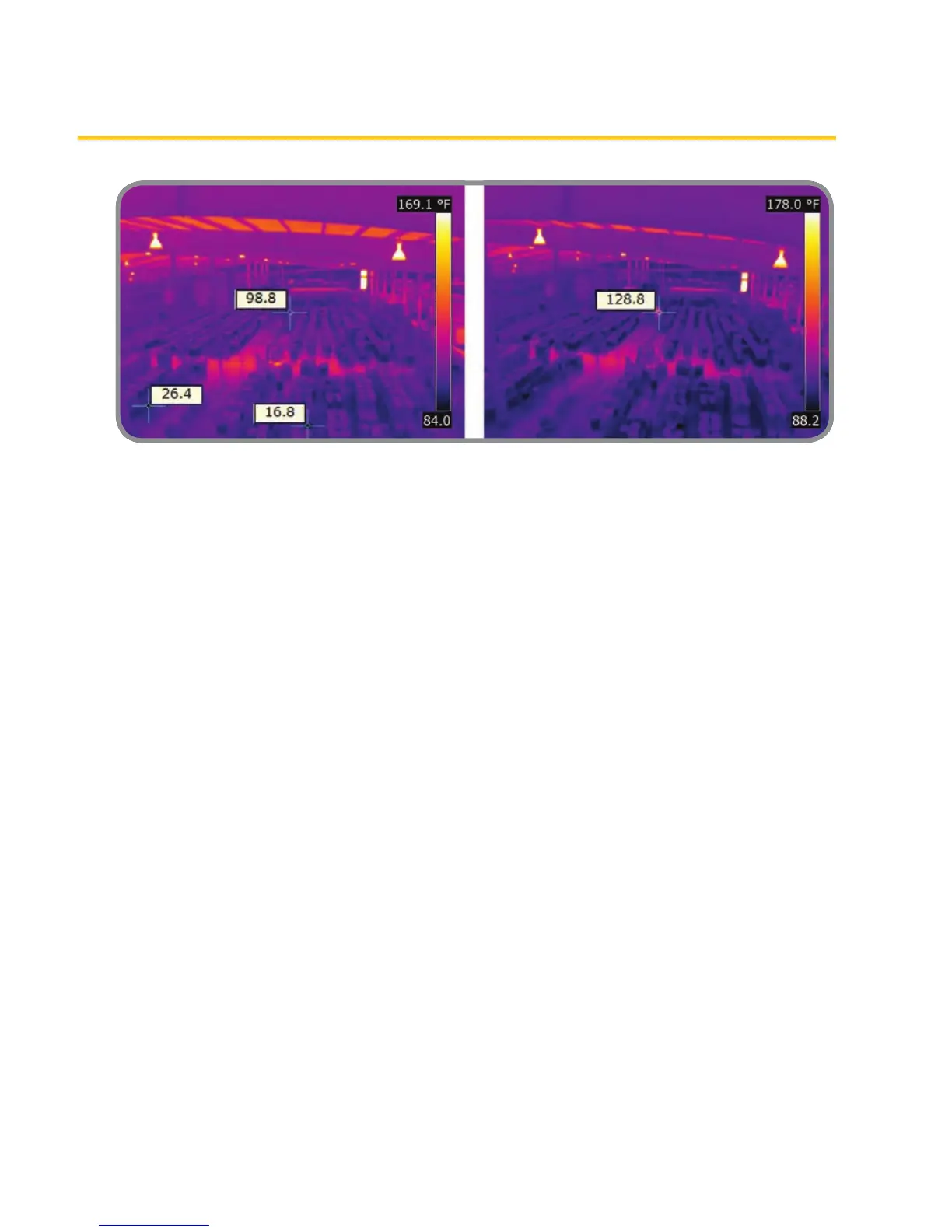

Figure 2a. IR image of a hazardous waste storage

area showing two spot temperature readings

(26.4°F and 16.8°F) that are in the safe range, plus

one reading (98.8°F) that is abnormally high.

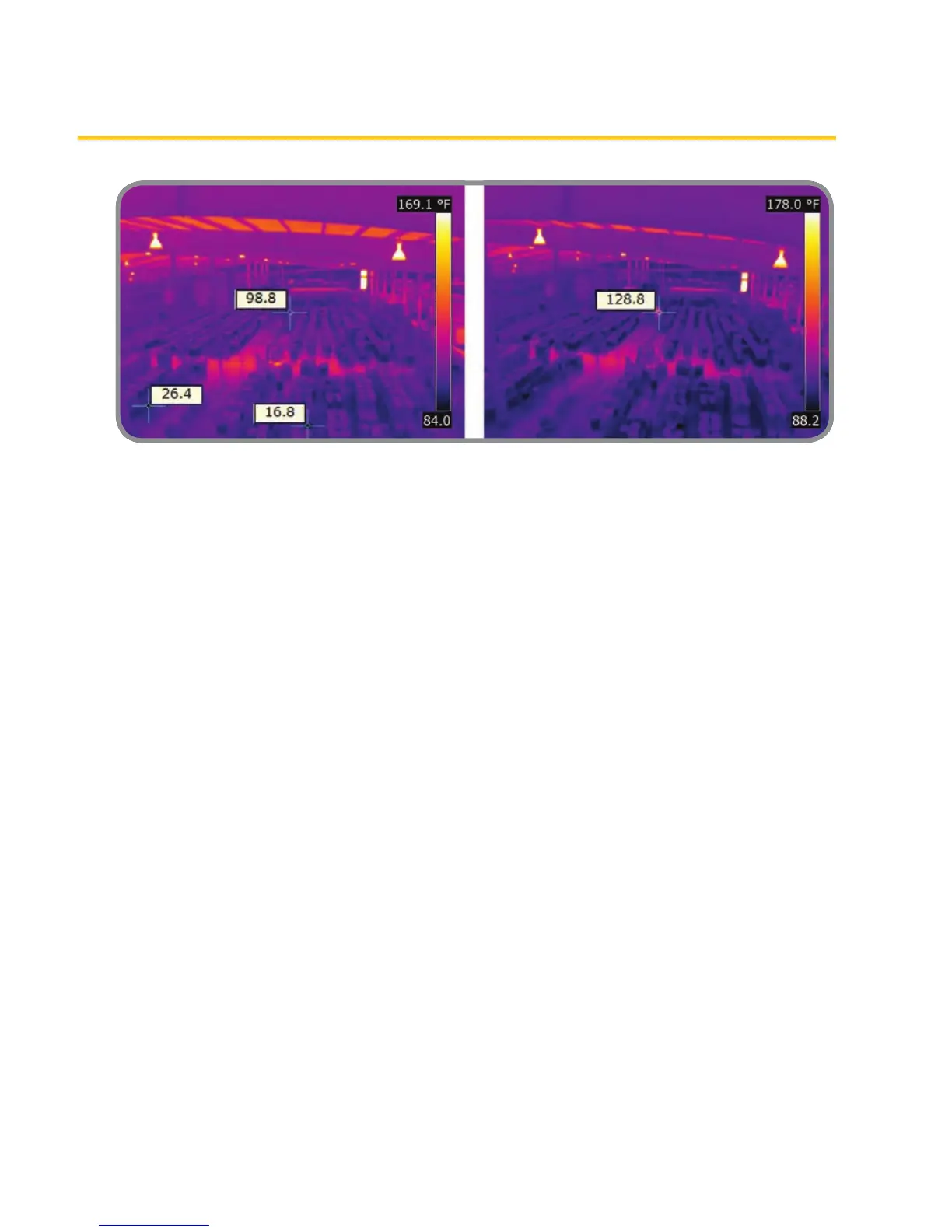

Figure 2b. A subsequent image of the same

area shows that the abnormal reading in 2a

has increased further, causing an alarm to

go o.

Loading...

Loading...