25

Combining Machine Vision and

Temperature Measurement

Combining Machine

Vision and Temperature

Measurement

Background

Traditionally, visible light cameras have

been a mainstay in machine vision

systems used for automated inspection

and process control. Many of these

systems also require temperature

measurements to assure product quality.

In numerous cases, an IR camera can

supply both an image of the product

and critical temperature data. If the

application will not benet from

thermographic images and non-contact

temperature measurements, then a

visible light camera is certainly less

expensive. If the opposite is true, then an

IR camera should be considered by the

system designer.

As the sophistication of IR cameras

continues to increase, along with

associated hardware and software, their

use in automated systems is growing

rapidly. Because of their combined

imaging and temperature measurement

capabilities, they can be very cost

eective. The main impediment to their

wider usage is system designers’ lack

of familiarity with IR camera features

and the related standards, systems, and

software that support them. This chapter

supplies a good deal of that information.

Machine Vision Applications

As in the case of visible light cameras,

thermographic cameras and their

associated software can recognize the

size, shape, and relative location of

target objects (i.e., they can do pattern

matching). Moreover, the electronics

in newer IR cameras provide fast signal

processing that allows high video frames

rates (60Hz or higher) to capture relatively

fast-moving parts on a production line.

Their A/D converters combine short

integration times with 14- to 16-bit

resolution, which is critical for properly

characterizing moving targets or targets

whose temperatures change rapidly.

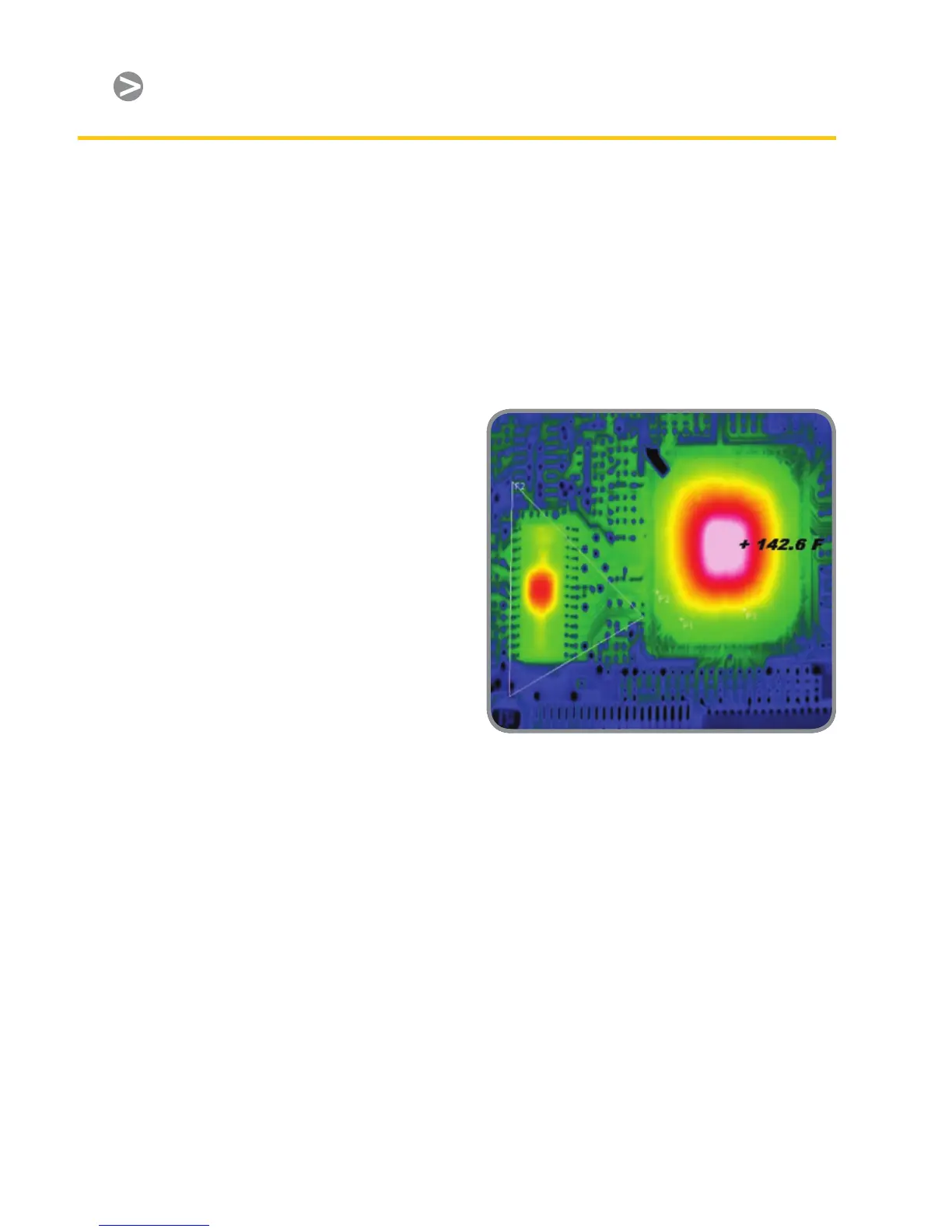

Figure 1. Results of automated inspection of ICs

on a circuit board

One example of the latter is automated

inspection of operating ICs on a circuit

board (Figure 1). In some cases, this

involves overload testing in which an

IC is subjected to a current pulse so its

heat loading can be characterized. In one

such case the IC is forward and reverse

biased with current levels outside of

design limits using a pulse that lasts

800ms. The IR camera captures images

during and after the current pulse to

characterize temperature rise and fall.

With a 60Hz frame rate, a new frame can

be captured about every 17ms. In such a

system nearly 50 frames can be captured

during the 800ms pulse, and many more

Chapter 4

Loading...

Loading...