26

Chapter 4

are typically captured afterward to reveal

heat dissipation characteristics.

In other applications of this sort, a good

image can be stored and compared to

the inspection image by using pixel-by-

pixel subtraction. Ideally, the resulting

image would be entirely black, indicating

no dierence and a good part. Areas

with excessive temperature dierences

indicate a bad part, making it very easy to

discern unwanted dierences.

There are many other applications

where the combination of non-contact

temperature measurements and imaging

at high frame rates is extremely valuable.

Some automated systems where IR

cameras are already being used include:

Automotive part production and •

assembly lines

Steel mill operations, such as slag •

monitoring and ladle inspection

Casting, soldering, and welding of •

metals and plastics

Food processing lines•

Product packaging•

Non-destructive testing, like sub-•

surface detection of voids in molded

parts

Electric utility equipment monitoring•

R&D, prototyping, and production in •

the electronics industry

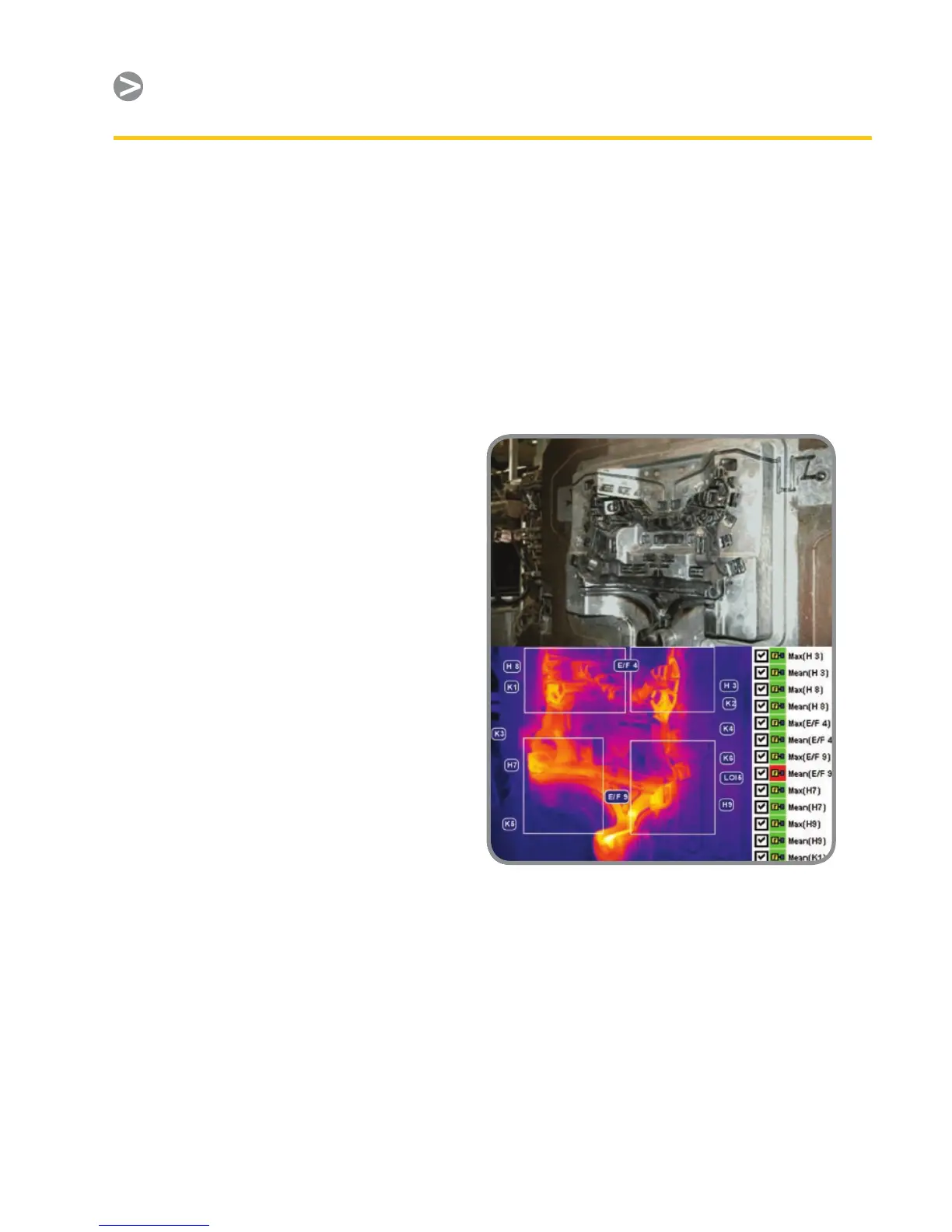

An interesting automotive example is

monitoring the temperature distribution

of a pressure casting mold for a safety-

critical part (Figure 2). Prior to installation

of the IR machine vision system, the

manufacturer was doing 100% inspection

using an X-ray system to reveal

subsurface imperfections. It was not

practical to do this as an inline procedure,

so the X-rays were taken a few hours after

part production. If the X-rays showed a

signicant problem in parts coming from

a particular mold, this information was

relayed to the production area so that

mold temperatures could be adjusted.

This was a lengthy and costly process that

often resulted in high scrap rates. With

the IR camera system, the mold operator

can immediately check and adjust the

temperature distribution of the mold.

Figure 2. Pressure casting mold and its

temperature distribution – an IR camera

image is used by the operator to adjust the

mold temperatures as required to produce

good parts.

Enabling Technology

Data communications are the backbone

of modern industrial SCADA, PLC, HMI’s,

and Machine Vision systems. Ethernet has

become the de facto standard for such

systems. Considering this, the features of

Loading...

Loading...