13

Remote IR Monitoring

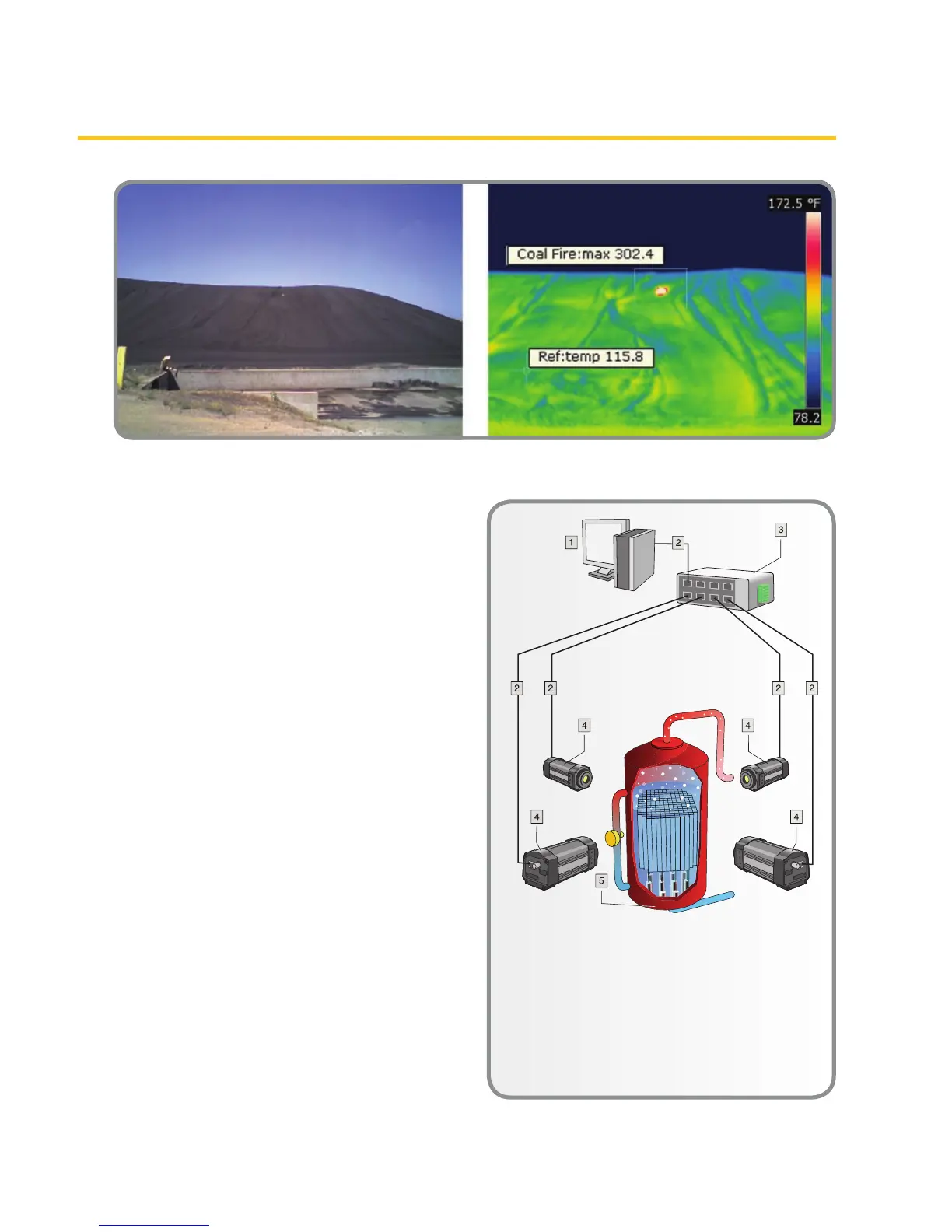

Figure 8. Visible light and IR images of a coal pile – the thermographic image clearly identies a hot

spot that is a re about to erupt.

on the application environment, an

explosion proof housing for the camera

may be a requirement. HMI (human-

machine interface) software, such as

SCADACAM iAlert from Pivotal Vision,

can be used to provide a monitoring

overview. This has the ability to combine

all of the camera images into a single

spatial representation of the monitored

area – in this case, a attened-out view

of the vessel. This view can be updated

continuously for a near-real-time

thermographic representation.

Electrical Substation Monitoring. Reliable

operation of substations is crucial for

uninterrupted electrical service. Besides

lightning strikes and large overloads,

aging equipment and connections are

a major cause of infrastructure failures

and service interruptions. Many of these

failures can be avoided with eective

preventative maintenance monitoring.

Often, the temperatures of transformers,

breakers, connections, etc. will begin to

creep up before a catastrophic failure

occurs. Detection of these temperature

increases with IR cameras allows

preventative maintenance operations

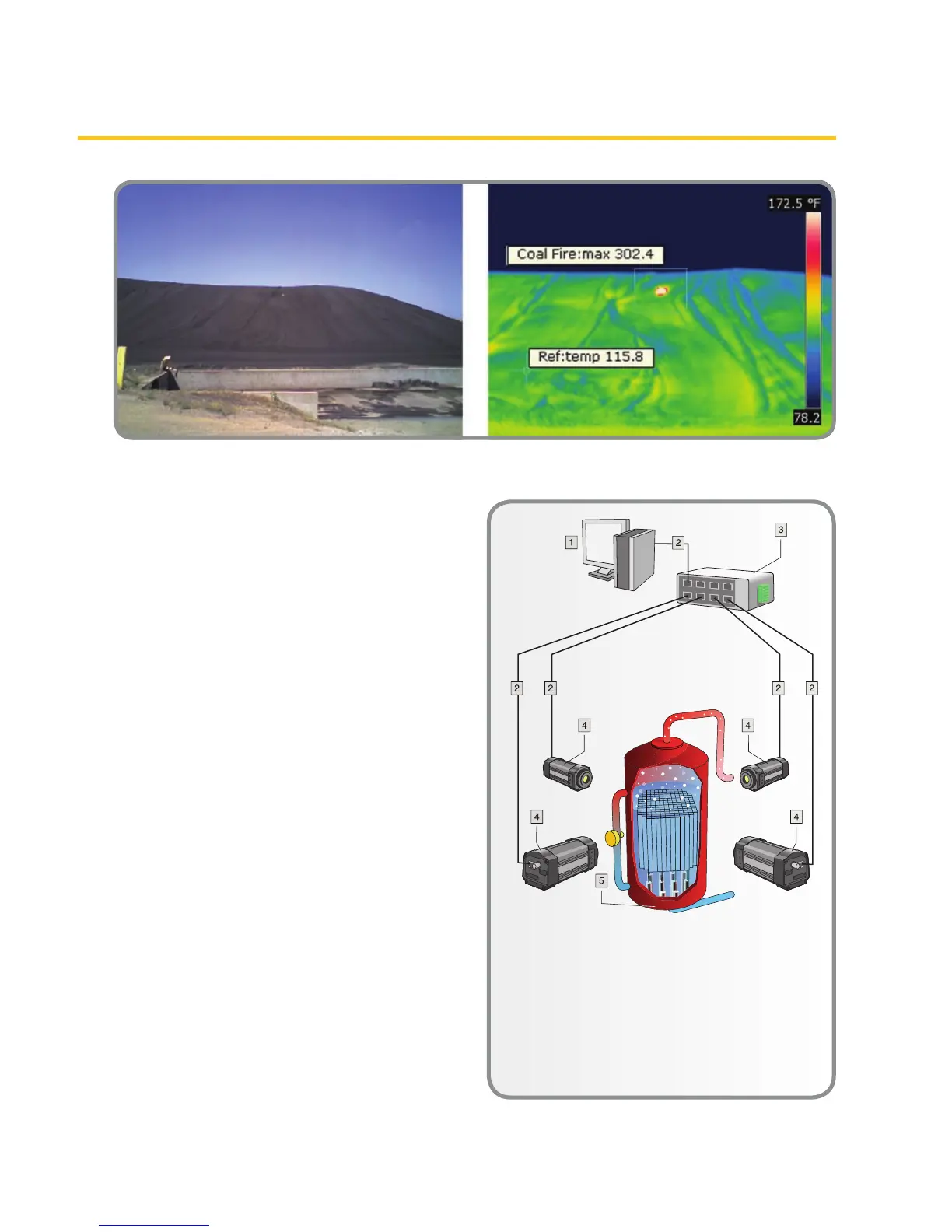

Figure 9. CVM monitoring example showing

camera locations, network connections, and PC.

1 Computer

2 CAT-6 Ethernet cable with RJ45

connectors

3 Industrial Ethernet switch with PoE

4 ThermoVision™ A320 cameras

5 Industrial process to be monitored,

e.g., a gasier

Loading...

Loading...