30

Chapter 4

and includes the ability to dene

complex pass/fail decisions, control

digital I/O, and communicate with serial

or Ethernet devices, such as PLCs, PCs,

and HMIs. Similar features are available in

Common Vision Blox, a Stemmer Imaging

product that contains hardware- and

language-independent tools and libraries

for imaging professionals.

By using third party software to get much

of the analytics, command, and control

functions out of the camera and onto a

PC, application possibilities are greatly

expanded. One possibility is creating a

mixed camera system. For instance, IR

cameras could be used to supply thermal

images and temperature data, while

visible light cameras could provide “white

light” color recognition.

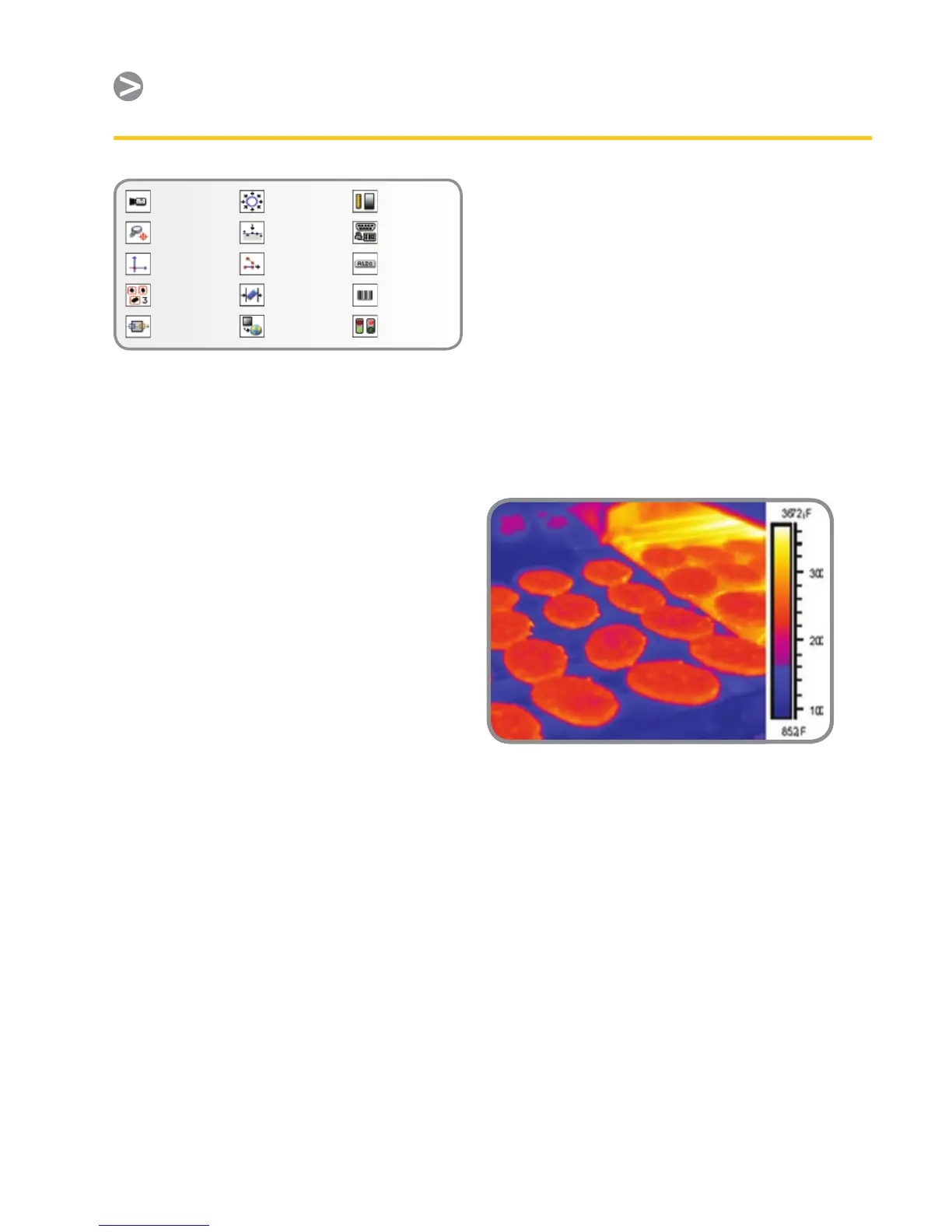

The food processing industry is one in

which higher level analytics are used with

IR cameras for automated machine vision

applications. A broad area of applications

where IR vision systems excel is in 100%

inspection of cooked food items coming

out of a continuous conveyor oven. A

primary concern is making sure the

items have been thoroughly cooked,

which can be determined by having

the camera measure their temperature,

which is illustrated in Figure 6 for

hamburger patties. This can be done by

dening measurement spots or areas

corresponding to the locations of burgers

as they exit the oven. If the temperature

of a burger is too low, the machine

vision program logic not only provides

an alarm, but also displays an image to

the oven operator to show the specic

burger that should be removed from the

line. As in other applications, minimum,

maximum, and average temperatures can

be collected for specic burgers or the

FOV as a whole and used for trending and

SPC purposes.

Figure 6. IR machine vision image for

checking hamburger doneness by measuring

temperature

In another example involving chicken

tenders, temperature is again used to

check for proper cooking. The pieces

come out of the oven and drop onto

another conveyor in more or less random

locations (Figure 7). The operator can

use the thermographic image to locate

undercooked items within the randomly

spaced parts and then remove them from

the conveyor.

In the production of frozen entrées,

IR machine vision can use pattern

recognition software to check for proper

lling of food tray compartments.

Loading...

Loading...