37

Real-Time Control Issues

camera rmware nds the minimum and

maximum temperatures and calculates

the average temperature inside the

area selected. Clearly, more processing

time is required for area measurements,

particularly if multiple areas are selected.

This also means that more data is being

transmitted over a machine vision

system’s communications network, along

with more latency.

Emissivity Calibration. Earlier, it was

pointed out that accurate temperature

measurements on a specic object

require the emissivity value for that

object. In eect, this adjusts the factory

calibration that is based on a perfect

blackbody having an emissivity value of

1.0. This adjustment consumes processor

time. To avoid this, the FLIR A325 uses a

global emissivity value (input by the user)

for the camera’s entire FOV. Normally,

this isn’t a problem for machine vision

applications and it avoids the time

required to apply non-global emissivity

values on the y. Instead, the application

program is set up to make decisions

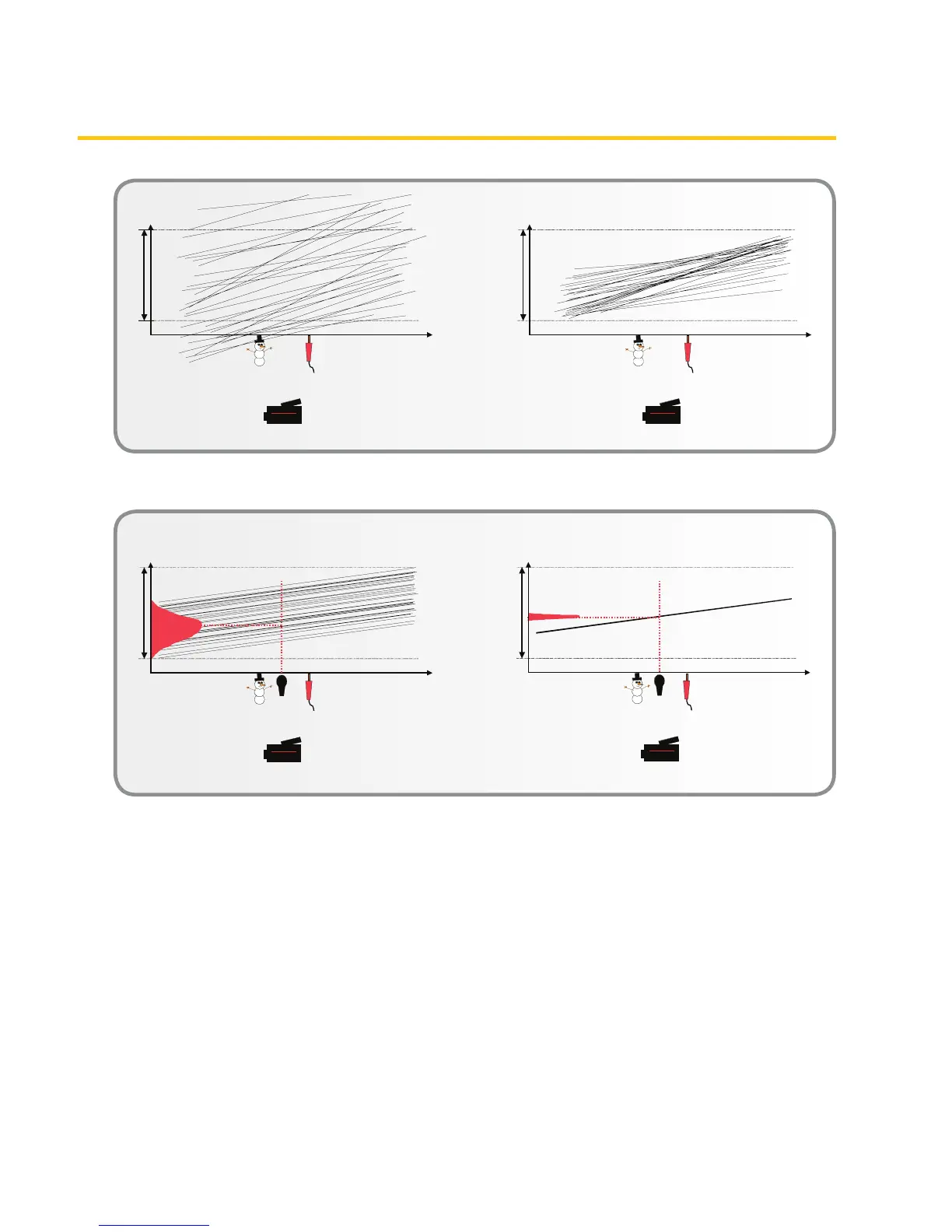

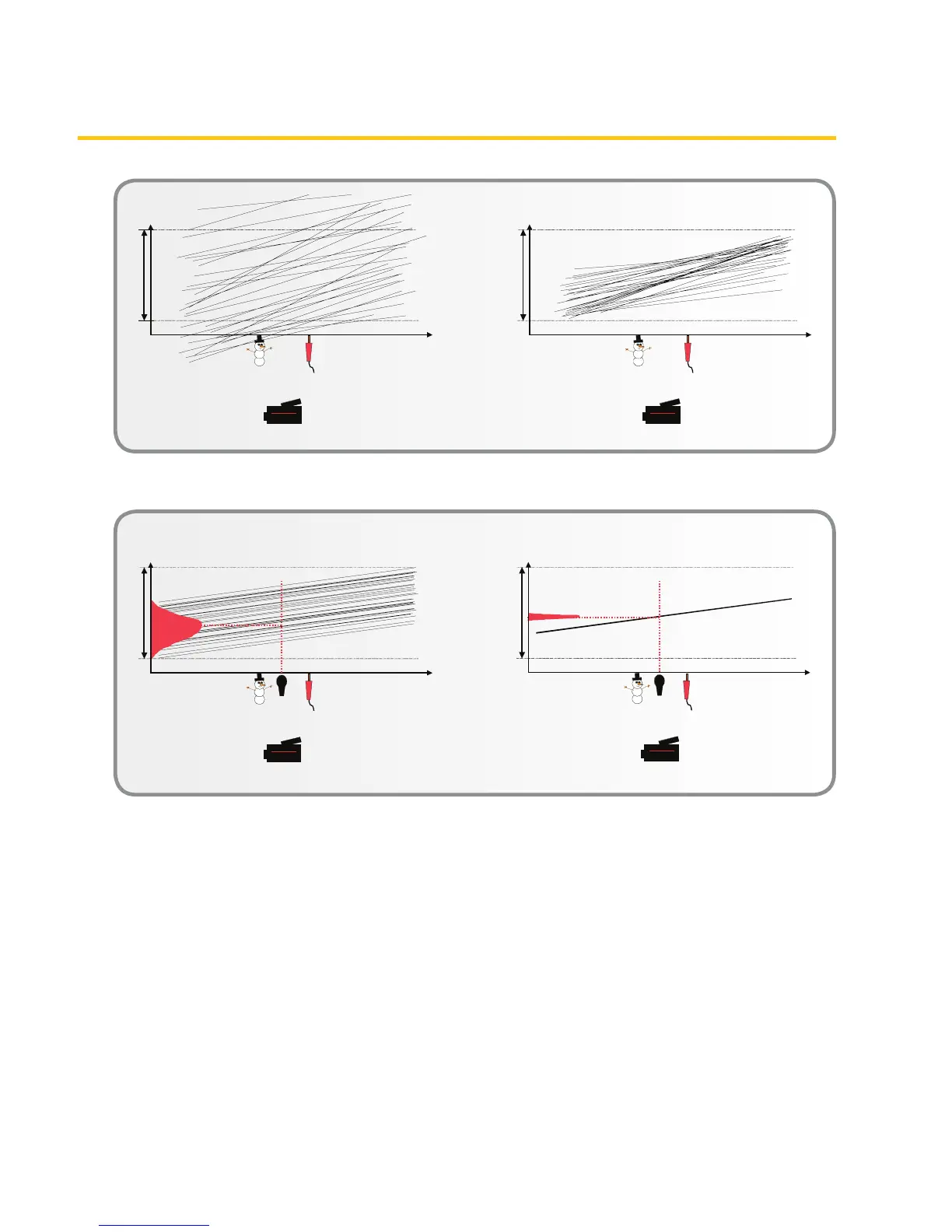

Figure 6b. Final steps in IR camera’s NUC process

Loading...

Loading...