39

Real-Time Control Issues

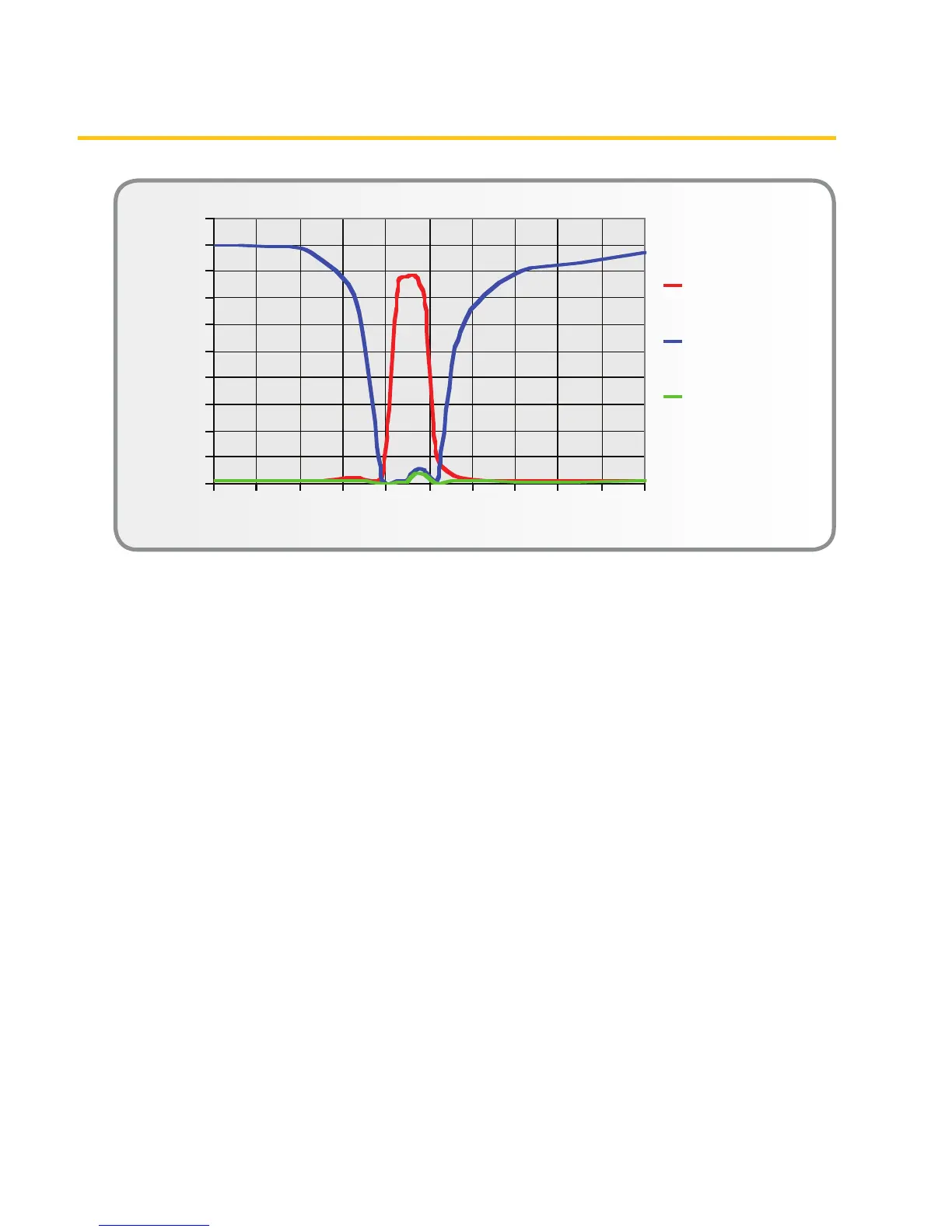

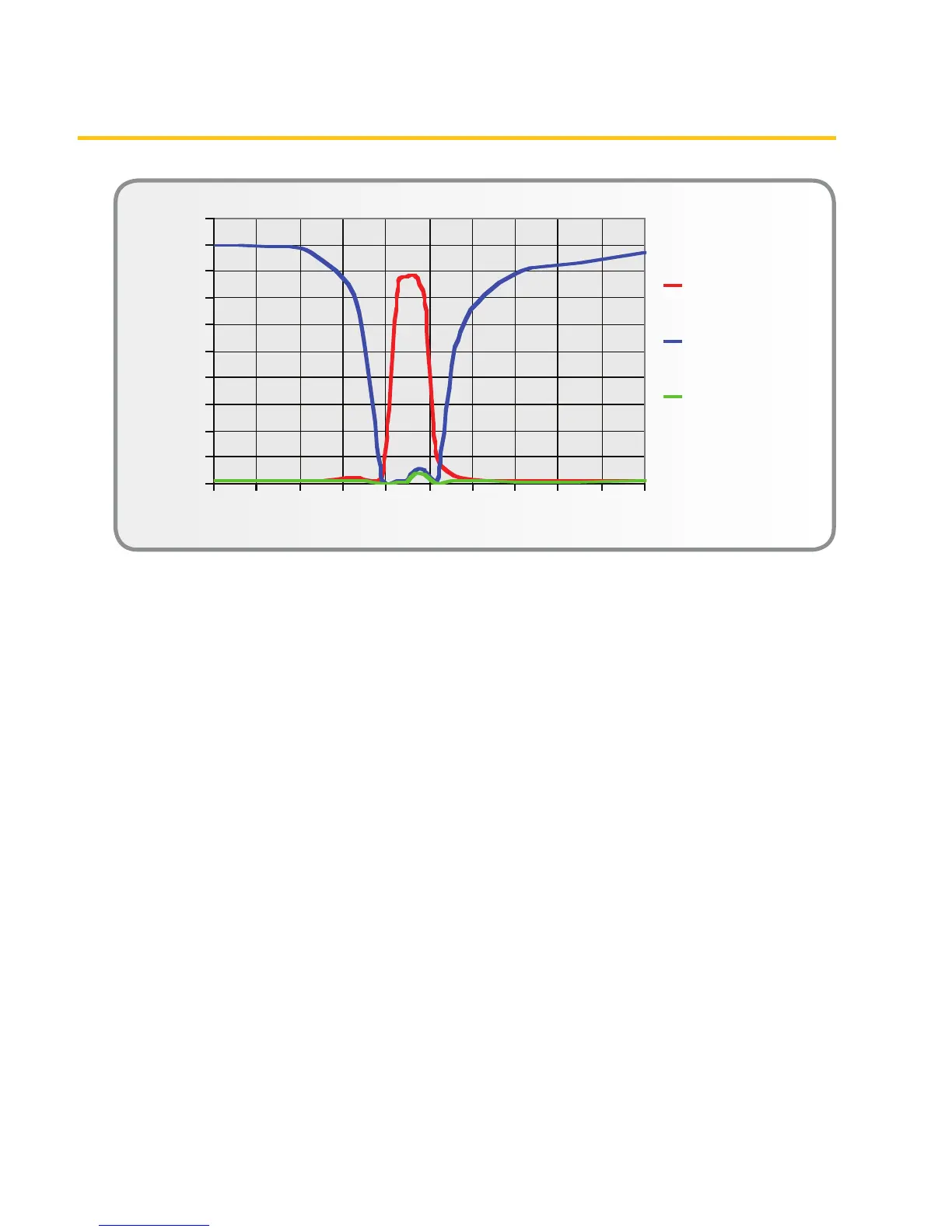

In the last two cases, spectral lters that

are selective at specic wavelengths

can help. Certain lters can make an

otherwise opaque gas appear transparent

or a transparent object appear opaque

over the appropriate IR band (Figure 8).

Summary

IR cameras used in machine vision and

other automation systems are analogous

to visible light cameras in similar systems.

White light cameras have optical issues

that must be managed, whereas IR

cameras have thermographic issues to

resolve. In both cases, achieving real-time

(or near-real-time) response requires

thoughtful selection of the controller

and careful design of the application

program. Third party software can

provide out-of-the-box program

development tools that eliminate or

minimize the need to write program

code. Generally, there are no perfect

solutions – developing an automated

machine vision system, whether based

on visible light or IR, usually involves

compromises of one sort or another.

The camera manufacturer can be a

great source of help in developing

these systems.

Loading...

Loading...