Valtek GS General Service Valve FCD VLENIM0300-00-A4 08/14

19

flowserve.com

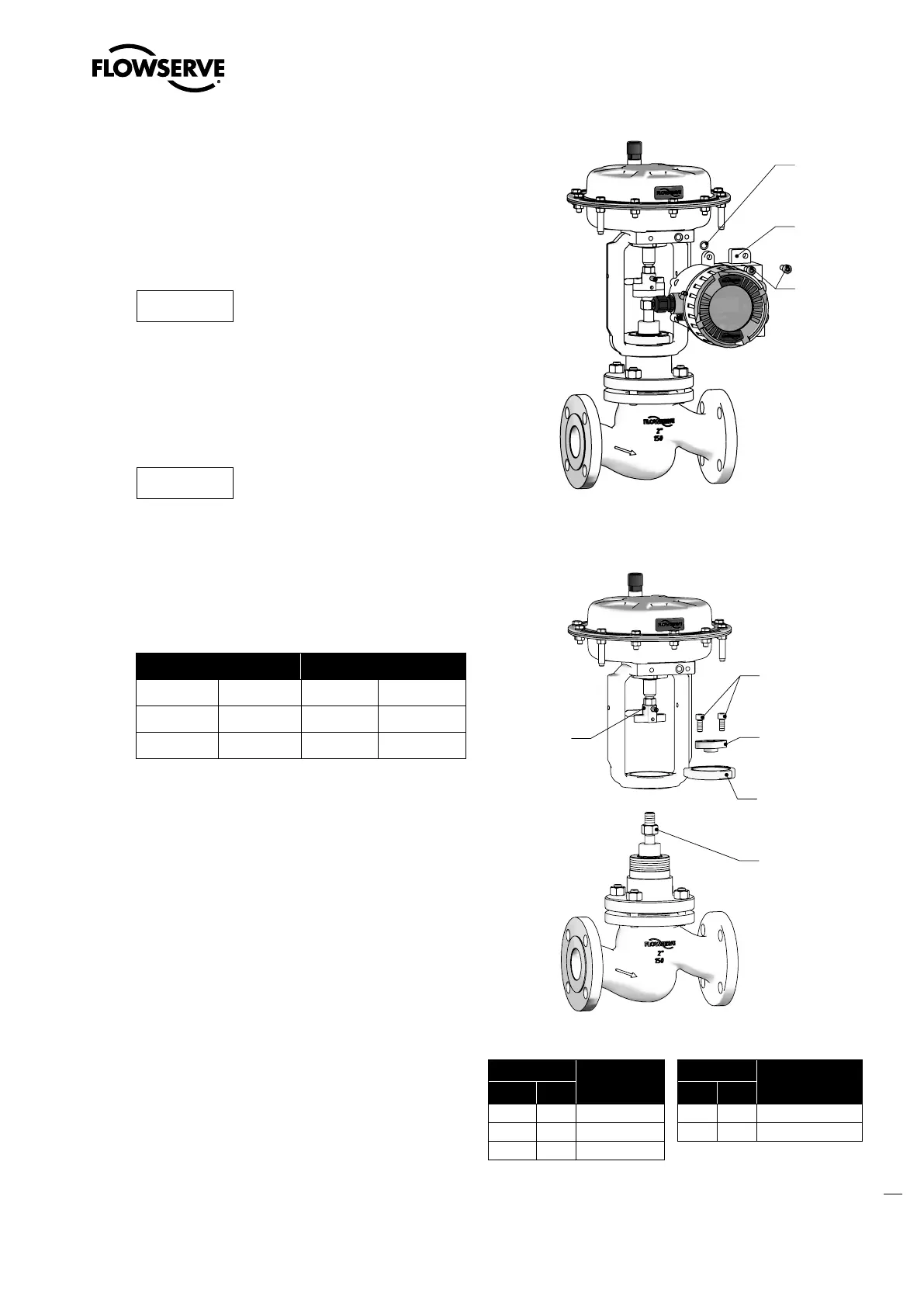

O-ring

Positioner

Figure 14: Remove the positioner

240

345

76

113

249

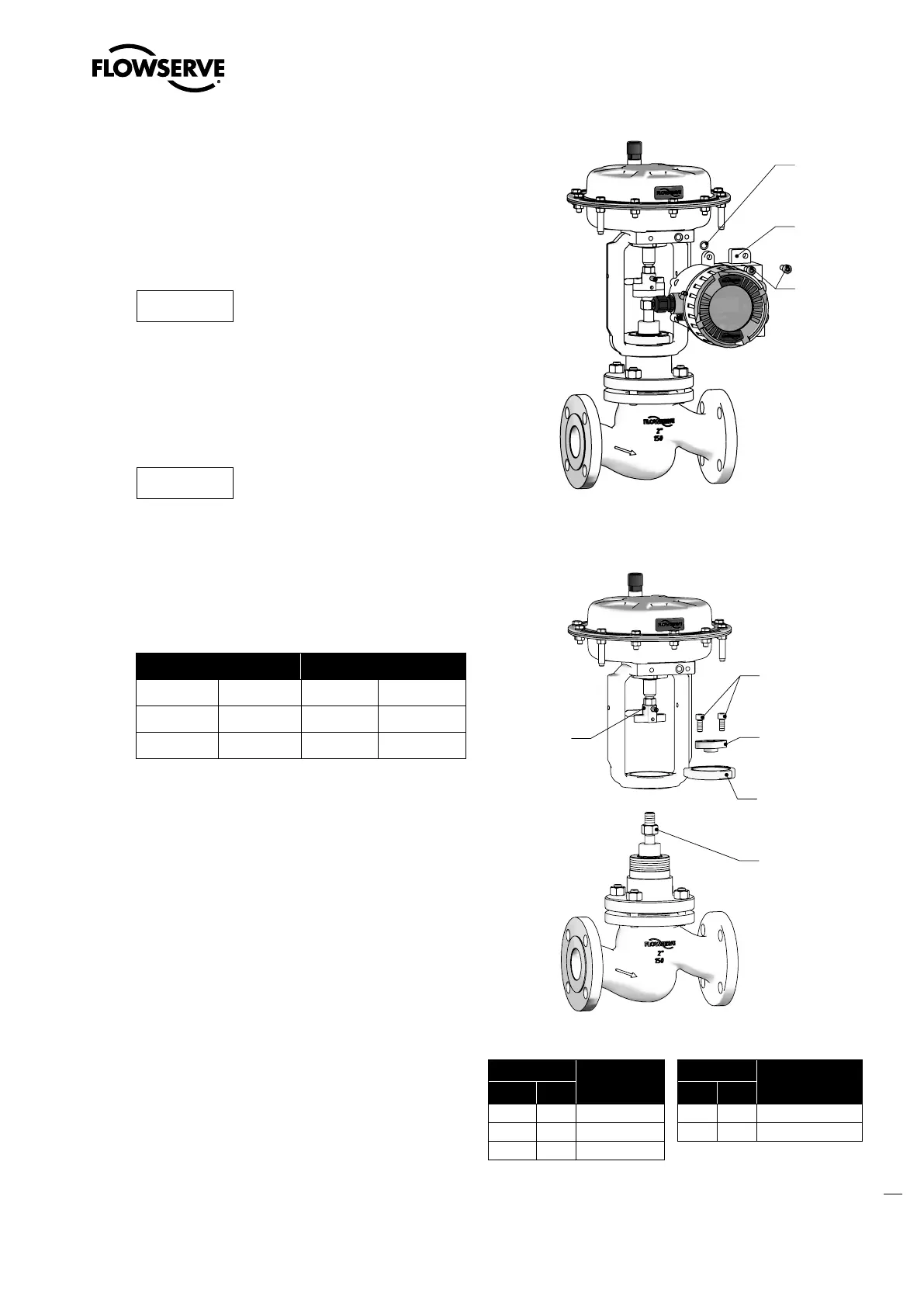

Figure 15: Remove the actuator

Item

Part

Item

Part

WW

1)

EU

2)

WW EU

76 5.10 Yoke lock nut 249 5.3 Upper coupling

113 5.2 Lock nut 345 5.1 Lower coupling

240 5.5 Cap screw

Table 16: Coupling parts identification

1)

WorldWide

2)

European Union

Reassemble the actuator and positioner

onto the valve:

1. Mount the pneumatic diaphragm or multi-turn actuator

onto the bonnet and tighten the yoke lock nut (76)

clockwise (See Section 14: Required Torques).

NOTICE

The legs of the yoke should be parallel

to the flow direction.

2. Move the actuator to the open position.

3. Screw in the lower coupling (345) three turns and

move the actuator into the closed position.

NOTICE

The plug must be aligned onto the

seat. The cushioning effect of the bel-

lows can be prevented by tightening the packing follower.

4. Move the actuator back into the open position and

adjust the distance between the lower coupling (345)

and upper coupling (249) by adjusting the stroke

length.

Size Stroke

15 - 50 1/2“ - 2“ 20

+ 0,5

mm 0.787

+ 0.02

in.

65 - 100 3“ - 4“

40

+ 0,5

mm 1.574

+ 0.02

in.

125 - 150 6“ 60

+ 0,8

mm 2.362

+ 0.03

in.

Table 15: Stroke adjustment length

5. Move the actuator to the close position and install the

cap screws (240).

6. Lock the lock nut (113). Keep upper coupling (249)

from turning by securing with a wrench.

7. Reassemble the positioner on the valve as necessary

(See relevant accessory User Instruction).

8. Connect the valve into the pipeline (See Section 9:

Installation).

9. After reinstalling the control valve into the pipeline,

perform three full strokes and check the tightness of

the packing follower and bonnet bolting (See Section

10: Valve Quick-Check).

10. Log the maintenance interval and the work performed.

Loading...

Loading...