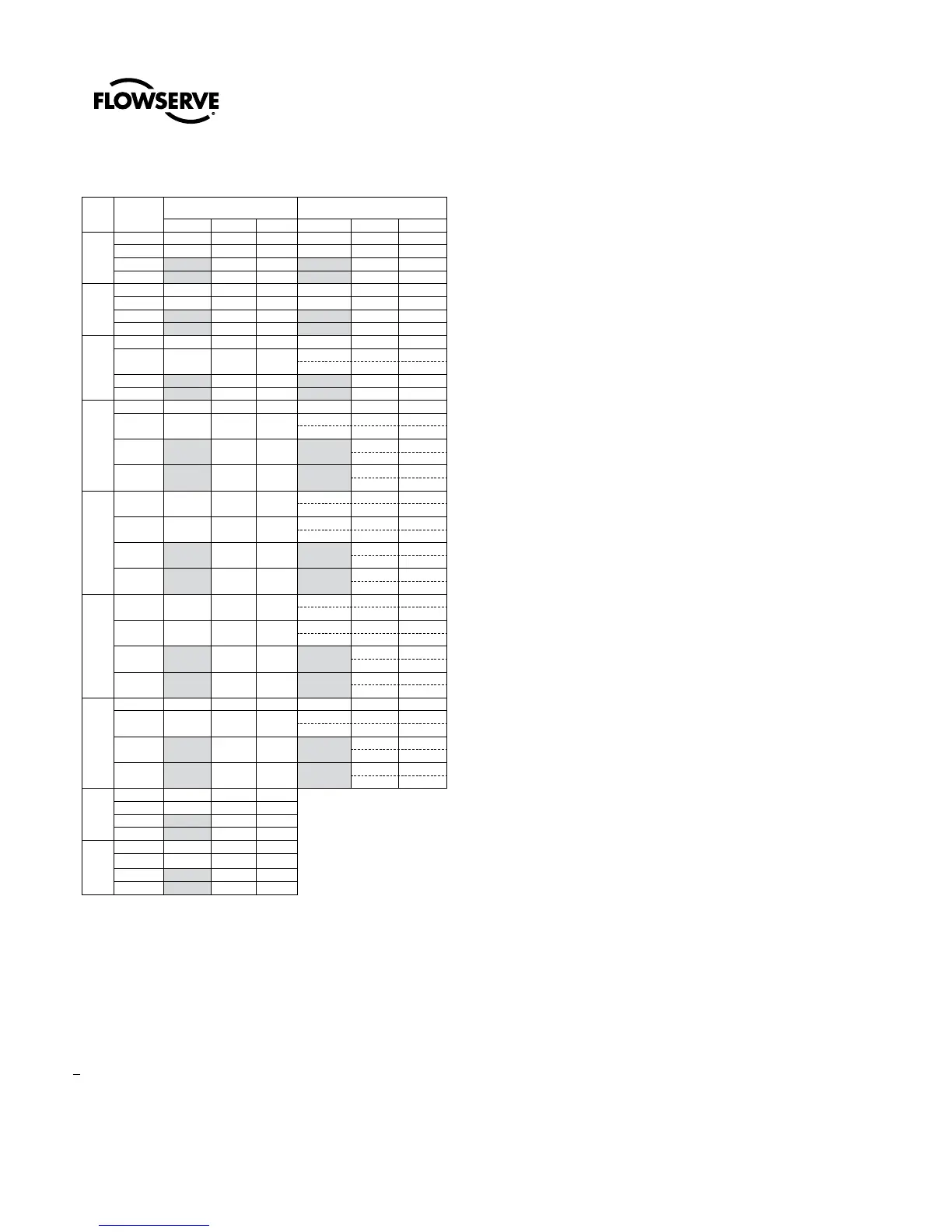

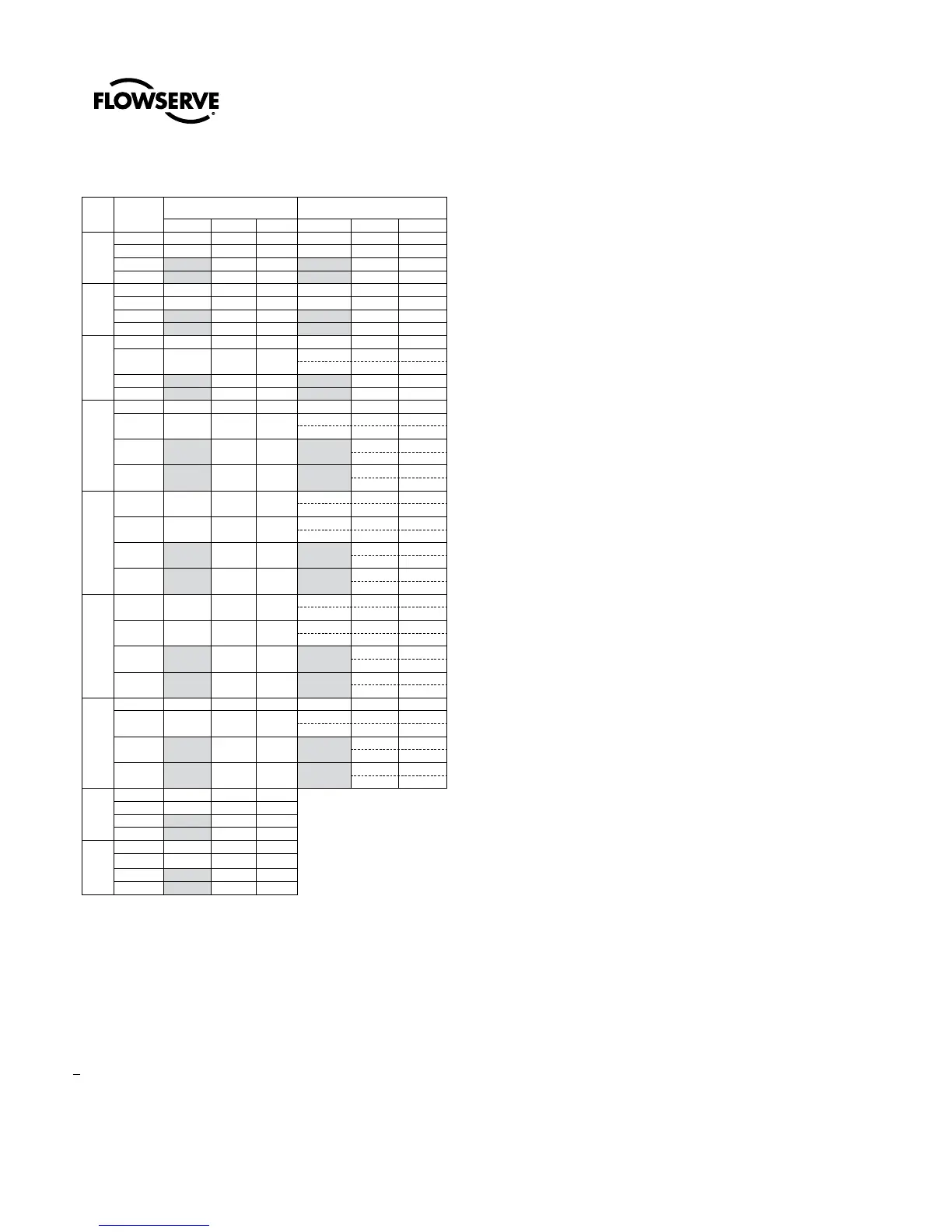

Table I: Line Flange Bolting Specifications

Valve

size

Nominal

Pressure /

Rating

MaxFlo 4 flanged

Size x Length

MaxFlo 4 flangeless

Size x Length

Inches Metric Qty/ valve Inches Metric Qty/ valve

DN25

1"

ANSI 150 1/2 X 2.62 M12 X 65 8 1/2 X 6.75 M12 X 170 4

ANSI 300 5/8 X 3.12 M16 X 80 8 5/8 X 6.88 M16 X 175 4

PN 16 M12 X 70 8 M12 X 175 4

PN 40 M12 X 70 8 M12 X 175 4

DN40

1½"

ANSI 150 1/2 X 2.88 M12 X 70 8 1/2 X 7.50 M12 X 190 4

ANSI 300 3/4 X 3.62 M20 X 95 8 3/4 X 8.38 M20 X 215 4

PN 16 M16 X 80 8 M16 X 200 4

PN 40 M16 X 80 8 M16 X 200 4

DN50

2"

ANSI 150 5/8 X 3.25 M16 X 85 8 5/8 X 8.38 M16 X 215 4

ANSI 300 5/8 X 3.5 M16 X 90 16

5/8 X 3.50 M16 X 90 4

5/8 X 8.50 M16 X 220 6

PN 16 M16 X 85 8 M16 X 215 4

PN 40 M16 X 85 8 M16 X 215 4

DN80

3"

ANSI 150 5/8 X 3.62 M16 X 95 8 5/8 X 10.5 M16 X 265 4

ANSI 300 3/4 X 4.25 M20 X 110 16

3/4 X 4.25 M20 X 110 4

3/4 X 11.00 M20 X 280 6

PN 16 M16 X 85 16

M16 X 85 6

M16 X 255 5

PN 40 M16 X 95 16

M16 X 95 6

M16 X 265 5

DN100

4"

ANSI 150 5/8 X 3.62 M16 X 95 16

5/8 X 3.62 M16 X 95 4

5/8 X 11.5 M16 X 295 6

ANSI 300 3/4 X 4.5 M20 X 115

16 3/4 X 4.5 M20 X 115 4

3/4 X 12.25 M20 X 315 6

PN 16 M16 X 85 16

M16 X 85 6

M16 X 285 5

PN 40 M20 X 100 16

M20 X 100 6

M20 X 300 5

DN150

6"

ANSI 150 3/4 X 3.75 M20 X 105 16

3/4 X 3.75 M20 X 105 4

3/4 X 13.25 M20 X 340 6

ANSI 300 3/4 X 4.88 M20 X 125 24

3/4 X 4.88 M20 X 125 8

3/4 X 14.00 M20 X 360 8

PN 16 M20 X 100 16

M20 X 100 4

M20 X 335 6

PN 40 M24 X 115 16

M24 X 115 4

M24 X 350 6

DN200

8"

ANSI 150 3/4 X 4.25 M20 X 110 16 3/4 X 4.25 M20 X 360 8

ANSI 300 7/8 X 5.5 M22 X 140 24

7/8 X 5.5 M22 X 140 4

7/8 X 15.19 M22 X 390 10

PN 16 M20 X 100 24

M20 X 100 8

M20 X 350 8

PN 40 M27 X 135 24

M27 X 135 8

M27 X 385 8

DN250

10"

ANSI 150 7/8 X 4.62 M22 X 120 24

ANSI 300 1 X 6.25 M24 X 155 32

PN 16 M24 X 110 24

PN 40 M30 X 150 24

DN300

12"

ANSI 150 7/8 X 4.75 M22 X 120 24

ANSI 300 1 1/8 X 6.75 M27 X 170 32

PN 16 M24 X 115 24

PN 40 M30 X 160 32

4 Quick-Check

Before commissioning, check the control valve by following these steps:

4.1 Check for full stroke by varying the instrument signal settings

appropriately. Observe the plug position indicator located on the

actuator or the positioner. The plug should change position with

a smooth turning movement.

4.2 Check all air connections for leaks. Tighten or replace any

leaking lines.

4.3 Check packing box bolting for proper tightness.

a CAUTION: Do not overtighten packing box bolting. This can

cause excessive packing wear and high stem friction that may

impede shaft movement. After the valve has been in service for

a short period, recheck the packing-box nuts. If the packing-box

leaks, tighten the nuts just enough to stop the leak.

4.4 Make sure the valve fails in the correct direction in case of air

failure. This is done by positioning the valve at mid-stroke and

turning off the air supply and observing the failure direction.

If the action is incorrect, see the section “Reversing the

Air-action” in the instructions of the installation, operation and

maintenance manual of the appropriate actuator.

5 Preventative Maintenance

At least once every six months, check for proper operation by following

the preventative maintenance steps outlined below. These steps may be

performed while the valve is in-line and without interrupting service. If

an internal problem is suspected, refer to section “Valve Disassembly”.

5.1 Look for signs of gasket leakage through the end flanges and

bonnet. If necessary, re-torque flange, bonnet and post bolting.

5.2 Examine the valve for damage, such as damage caused by

corrosive fumes or process drippings.

5.3 Clean the valve and repaint areas of severe oxidation.

5.4 Check the packing-box for proper tightness. If there is a persis-

tent leak, change the packing after referring to sections “Valve

Disassembly and Body Reassembly”.

a CAUTION: Do not overtighten packing box bolting. This can

cause excessive packing wear and high friction that may impede

shaft movement.

5.5 If the valve is equipped with a lubricator, add lubricant if necessary.

5.6 If possible, stroke the valve and check for smooth, full-stroke

operation. Unsteady shaft movement may indicate an internal

valve problem.

5.7 Check the calibration of the positioner. For further preventative

maintenance, see the instructions in the installation, operation

and maintenance manual for the applicable positioner.

Loading...

Loading...