FLUID COMPONENTS, INTL CHAPTER 1 - GENERAL INFORMATION

Model ST98 Flow Meter

1 - 2

Doc. No. 06EN003291 Rev. A

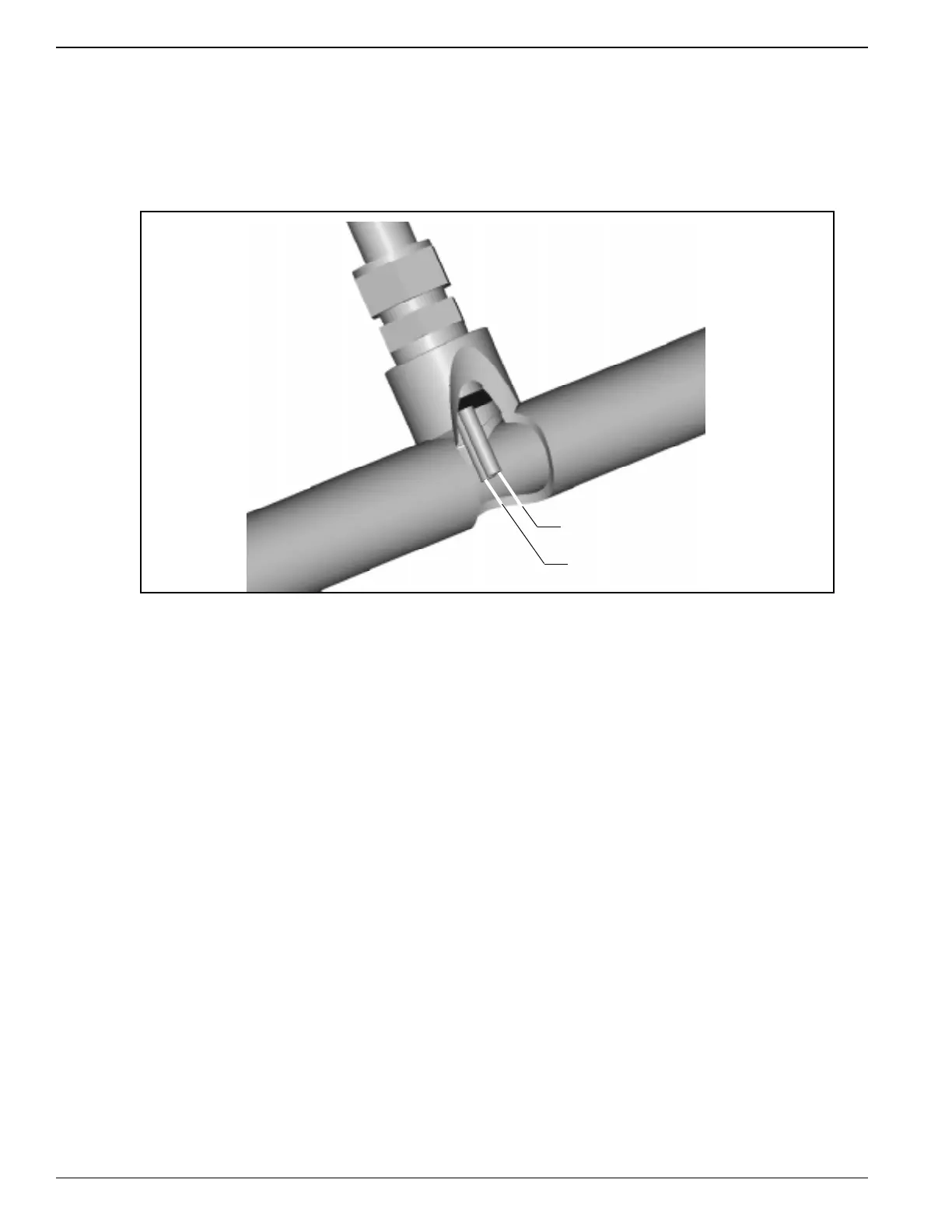

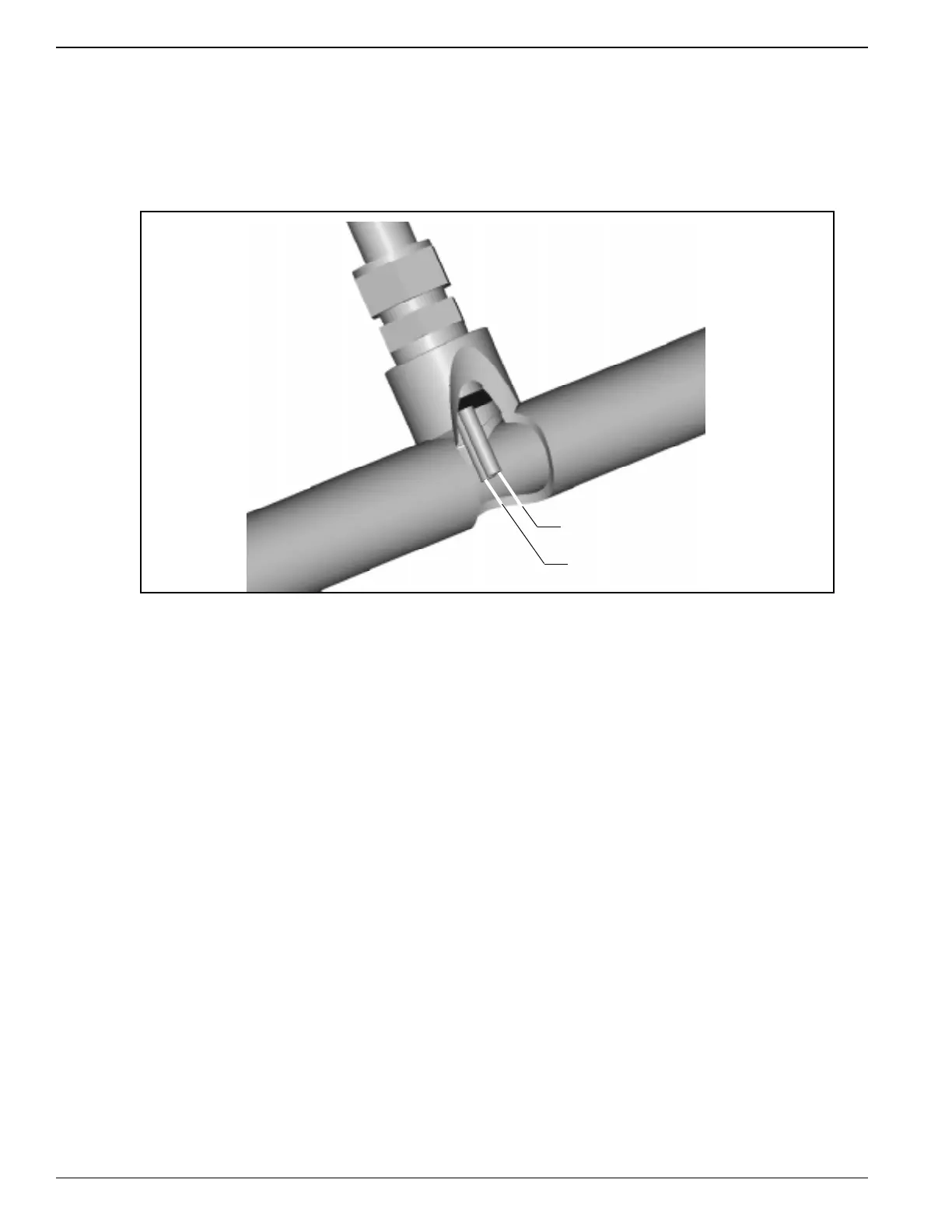

Figure 1-2. Cut-Away View Of The In-Line Flow Element Tube

ACTIVE (HEATED) RTD

REFERENCE (NOT HEATED) RTD

Transmitter Electronics

The transmitter electronics convert the sensing element's RTD temperature differential into a flow signal that is

read on a display . The transmitter also produces an analog output flow signal suitable to interface with process

controls. The output is a representation of the amount of flow or temperature present in the process. The flow

output is transmitted on a source milliamp output and / or voltage output. Both the flow output and process

temperature can be displayed on an optional LCD display.

There are 2 kinds of enclosures available for the electronics:

1. Standard:

Polyester Coated Carbon Steel Rated NEMA/CSA Type 4X (equivalent to IP66) and Division 2 (Ex n), Rating

is pending. (This is a 6 X 6 X 4 Inch Square Enclosure.) (152.4 X 152.4 X 101.6 mm)

2. Optional:

Aluminum rated for Hazardous Location use Class I and II, Division 1 and 2, Group B, C, D, E, F, G

(previously referred to as NEMA 7 and EEx d IIc) resists the effects of weather and corrosion.

(This is a 4.8 X 9.31 Inch Cylindrical Enclosure.) (121.8 X 236.47 mm)

Instrument Configuration

The instrument can be in integral arrangement (the electronics and the sensing element are combined in one

enclosure), or the instrument can be in a remote arrangement (the electronics and sensing element are in separate

enclosures).

In the case of a remote enclosure, the standard configuration of the sensing element (local) enclosure is an

aluminum rated for Hazardous Location use Class I and II, Division 1 and 2, Group B, C, D, E, F, G (previously

referred to as NEMA7) and EEx d IIC and resists the effect of weather and corrosion. The dimensions are 4.68 X

4.82 inches (119 X 122 mm) and is cylindrical in nature.

In-Line Sensing Element (Flow Tee)

The in-line sensing element is made in the same way as the insertion type of flow element is. To correctly orient

the in-line sensing element, a flow arrow has been etched onto one side of the sensing element.

The in-line flow element is inserted in the process line with the flow arrow pointing in the same direction of flow.

See Figure 1-2 for a cutaway view of the in-line element.

Loading...

Loading...