11

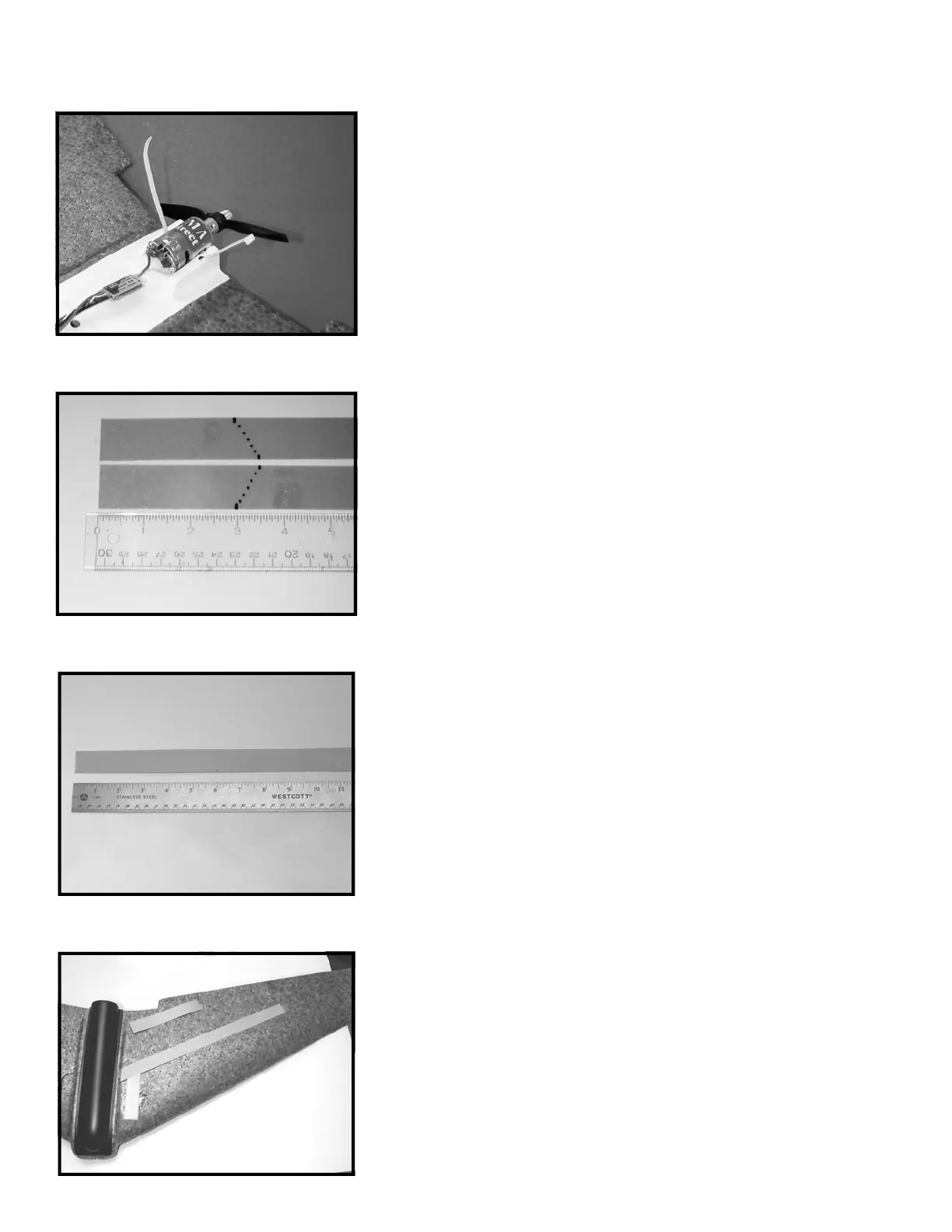

STEP 26: Locate two pieces of the 0.010” (thick) LEXAN

(TM)

tape. On

each piece of tape, mark one side at 3”; mark the other side at 3.5” as

illustrated. Cut each of the tapes across the equal but opposite

angles as in the illustration. You will end up with two short pieces of

tape to be used for holding the servos in place and two longer pieces

that will serve as the structural spars for the top sides of each wing

half.

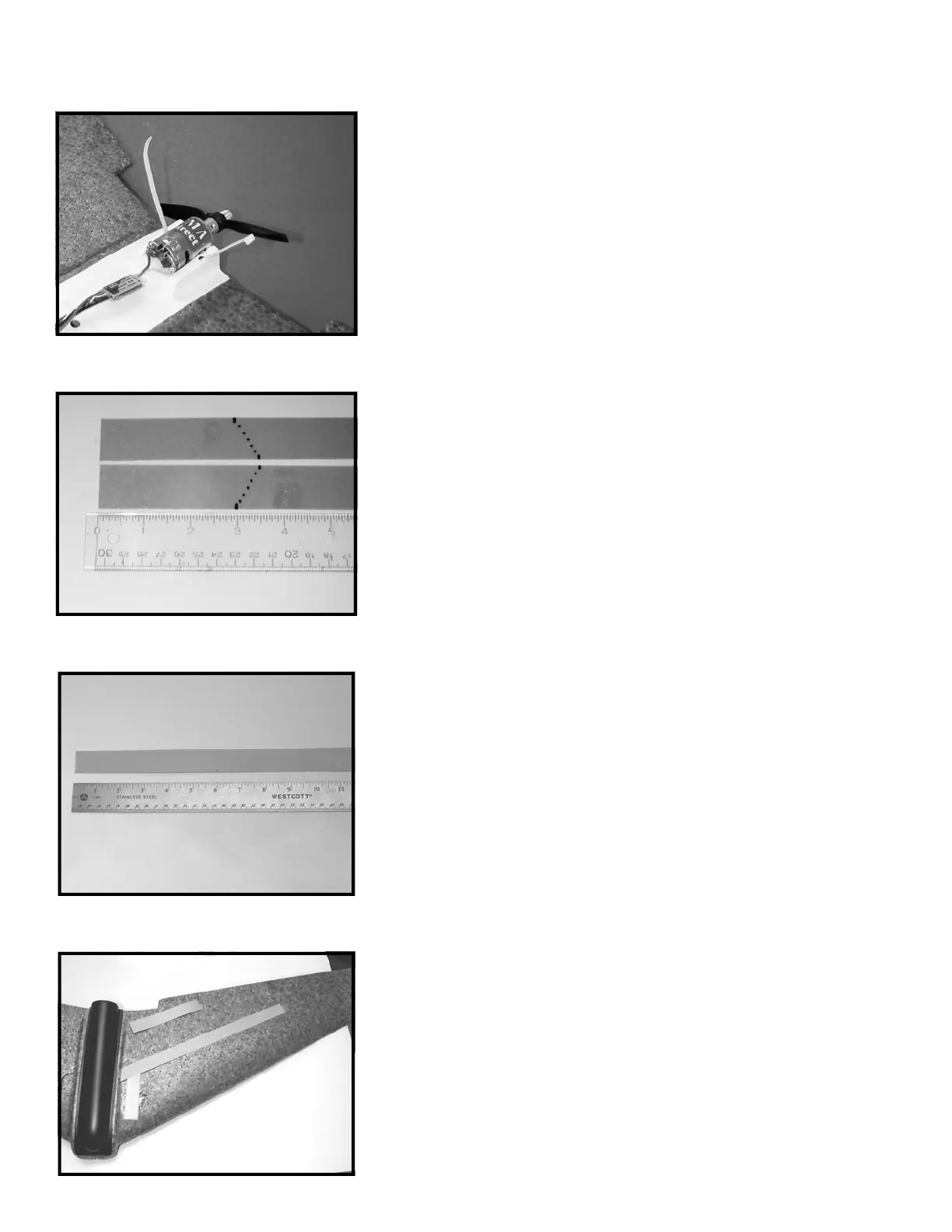

STEP 25: Assemble the motor pack to the equipment tray as

illustrated. Feed the nylon tie through the holes you cut in the motor

mount. Pull the nylon tie tight so that the clamp is resting closest to

either hole and cut off the excess.

STEP 27: Steps 27 and 28 apply to 400 class kits only! If you do not

have a 400 class kit, please proceed to step 29. If you have a 400 class

kit, locate the four pieces of 0.010” LEXAN

(TM)

tape provided. Two of

these have been cut slightly shorter in STEP 26 above and are angled

on one end. Mark and cut off 6” from the square ends of all four

pieces of tape. The 6” pieces will provide added structural support to

the wing where the prop cutout is molded into the trailing edge of the

wing. The two shorter pieces with the angle cuts on one end will be

used for structural support for the top of the wing. The two longer

pieces will be used for structural support for the bottom of the wing

where the most stress occurs in flight during loops.

STEP 28: This illustration shows the placement of the structural and

servo tapes prepared in STEPS 26 and 27 for a 400 class kit. Do not

install the tapes at this time, but test the placement of each as

follows. The long tape should be positioned so that the end closest to

the fuselage begins where the wing joins the fuselage and is centered

over the servo wire slot. The end closest to the wing tip should be

centered on the wing panel. The servo tape should butt up against

the structural tape and center over the servo. The front of this tape

should extend 1” beyond the servo case (toward the leading edge). If

required, trim the angle cuts slightly. Put the short servo tapes aside

as these will not be installed until radio installation is complete!

400 CLASS ONLY

400 CLASS ONLY

Loading...

Loading...