17

STEP 49: Screw the clevis onto the pushrods. Install the pushrods to

the servo output arms from the out-board side of the servo. Your kit

contains one left and one right pushrod. Before snapping the clevis to

the control horn, adjust the length of the rod so that when the

pushrods are installed, the elevons are set for 2 degrees up elevon.

You can judge 2 degrees as follows: the horizontal (level) axis of the

airframe is along the part line of the molded part. The part line can be

identified by small protrusions of foam that outline the entire

airframe; i.e. leading edge, trailing edge, wing tips. Hold the aircraft

such that the part line of the mold is parallel to the ground. The back

of the elevons should rise about 1/16” above this imaginary plane.

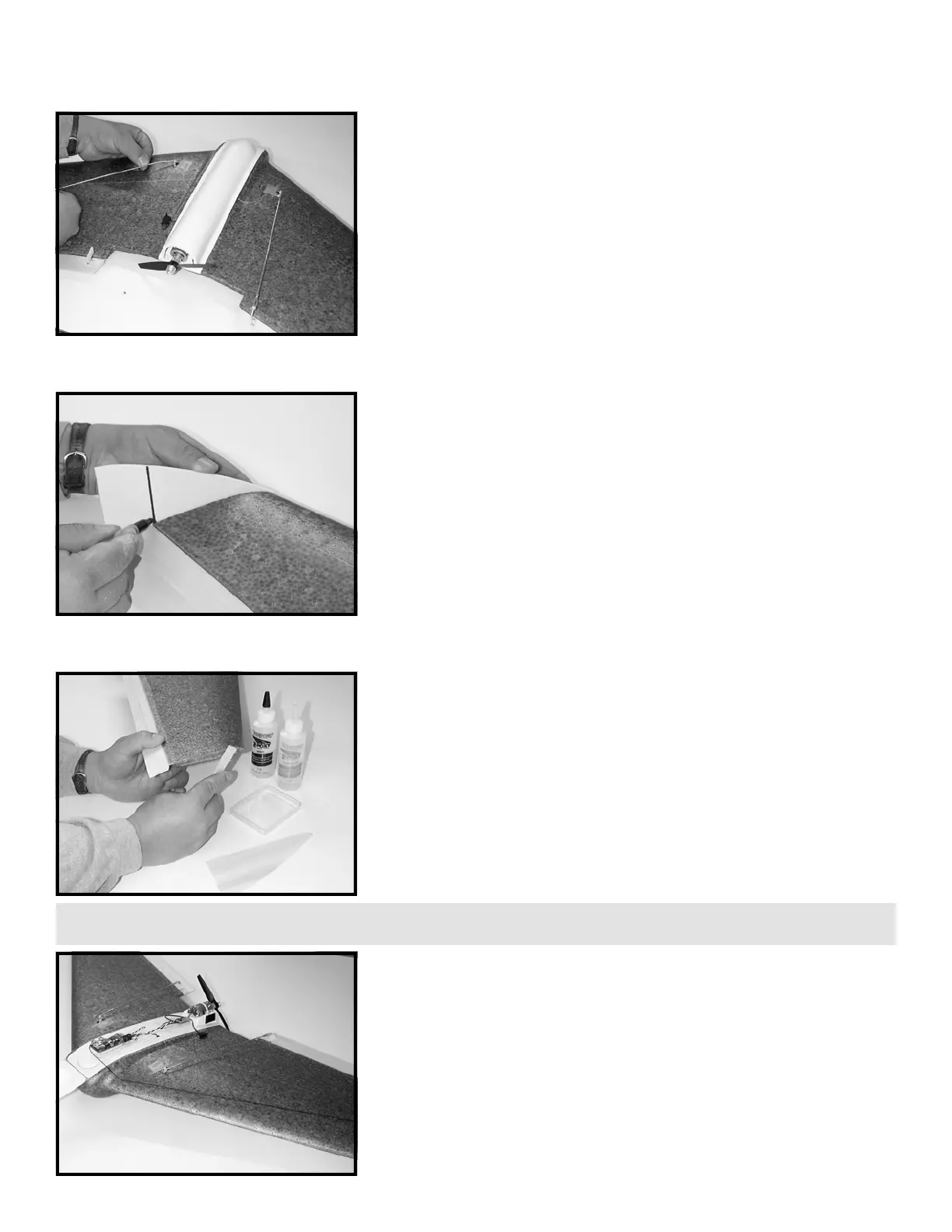

STEP 50: Round-off the top edge of the winglets. The shape of the

winglet on 400 Class kits is not critical. You may install them as is, or

you may change the size and shape to suit your tastes. For all 600

Class kits, it is mandatory that you reduce the length of the winglet

so that it does not protrude beyond the trailing edge of the wing. For

600 Class kits, hold the winglet up to the wing tip, mark and cut the

length of the winglet down as illustrated. Cutting down the winglets

for 600 Class models will greatly improve flight handling at slow

speeds, helping to prevent tip stall and snap roll.

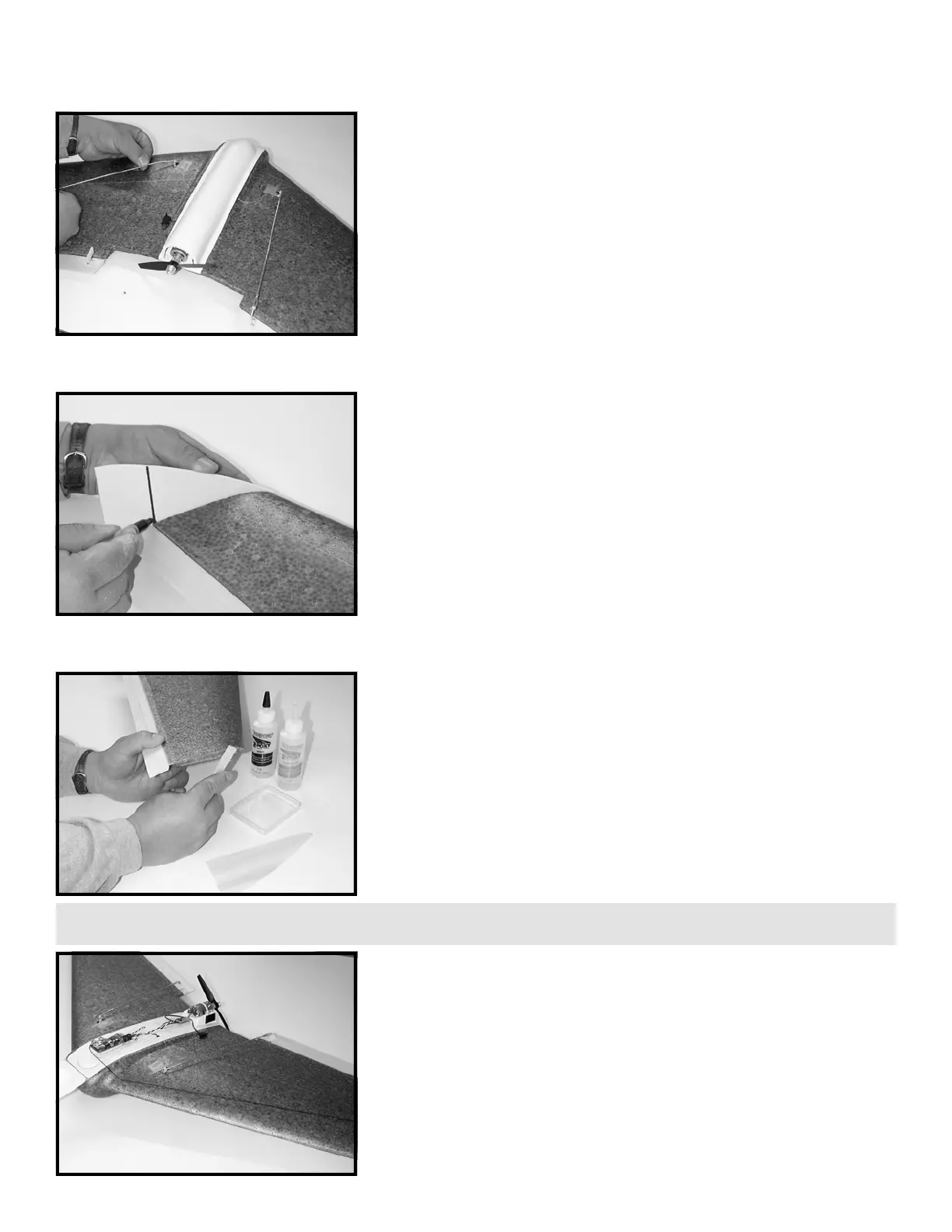

STEP 51: Mix a modest amount of 5 minute epoxy and apply to the

wing tip. Attach winglet to wing tip and align the underside of the

winglet to match the underside of the wing airfoil. Hold or tape in

place until glue sets. Repeat for other winglet.

STEP 52: Cut a small slot 1/8” deep and 1/2” long in the top of the

wing in front of the servo and directly in line with the front of the

receiver. Press the antenna into this slot using a small blunt dowel so

as not to damage the antenna wire. Use a small piece of 0.005” (thin)

LEXAN

(TM)

tape to “capture” the antenna in the slot but allow it to

move freely back and forth through the slot. This arrangement will

keep the antenna from coming in contact with the servo mechanism

but will allow you to open the battery hatch to change/charge

batteries. Route the antenna over the top of the wing toward the

back of the winglet. Drill two small holes in the winglet just ahead of

the trailing edge of the wing. Loop the antenna through these holes.

600 CLASS -

400 OPTIONAL

TIP: Optional antenna routing...drill a small hole through the wing about 1” back from the leading edge and directly opposite the back of the receiver.

Route the antenna to the underside of the wing and angle back to the outboard trailing edge. Drill another small hole there and route antenna back up.

Loading...

Loading...