16

G Operating instructions digital oval gear meter

6.3.4 Changing the K FACTOR directly

This procedure is helpful for the correction of a ‚mean error‘ that may be determined by monitoring a

certain number of output operations. In the event you observe a mean percentage error during normal

meter operation you may carry out a correction by changing the valid User K Factor by that percentage. In

order to calculate the correction of the USER K FACTOR, proceed as follows:

New calibration factor = old calibration factor x

Example:

Observed mean percentage error E % -0,9 %

Current K Factor 1.000

New USER K FACTOR 1.000 x 100-(-0,9)÷100=

1.000 x (100+0,9)÷100=

1.009

If the meter displays less than the actual amount of liquid output (negative error), the new K Factor must

be greater than the old one (see example). The opposite is true if the value indicated is greater than the

actual amount (positive error).

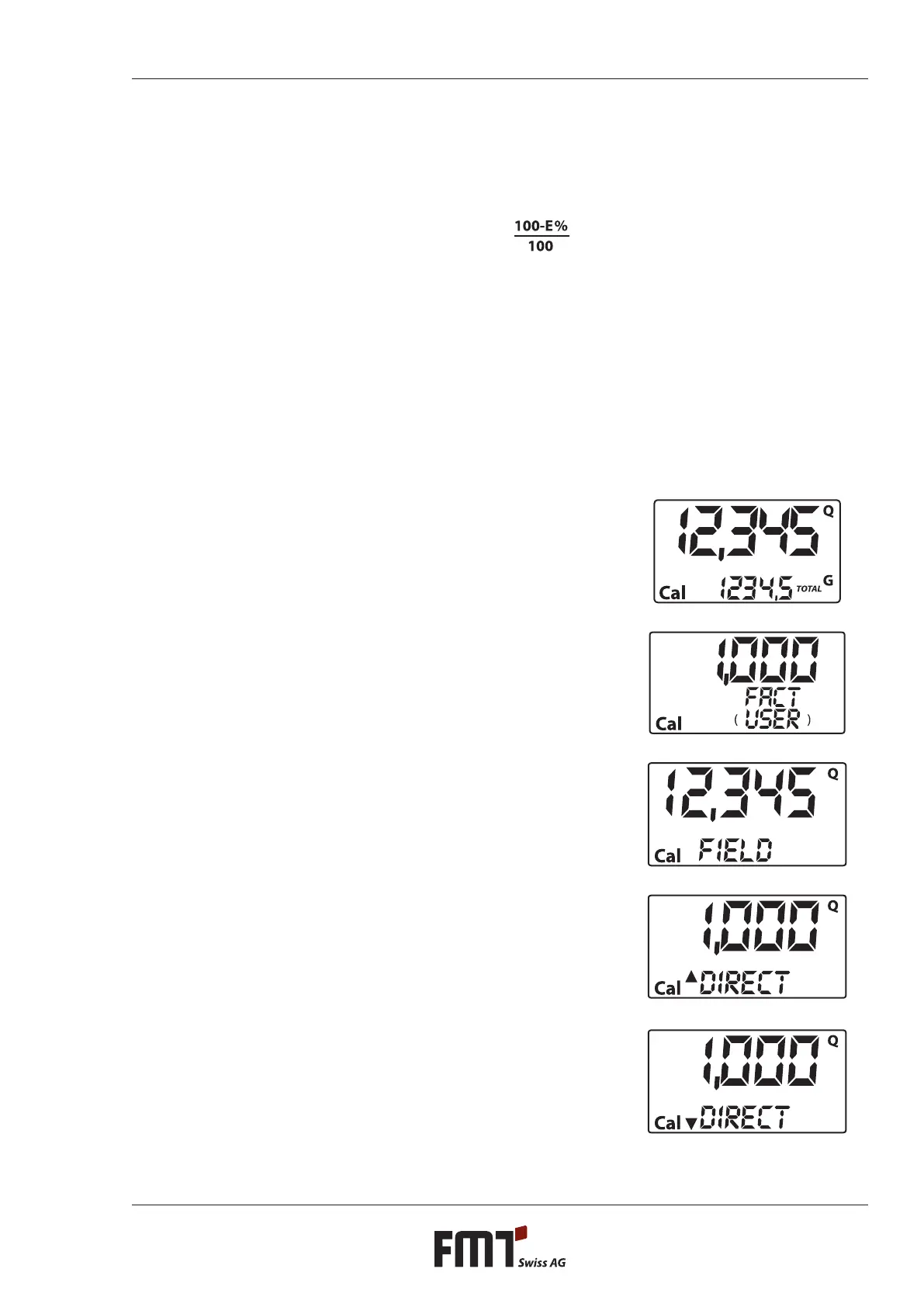

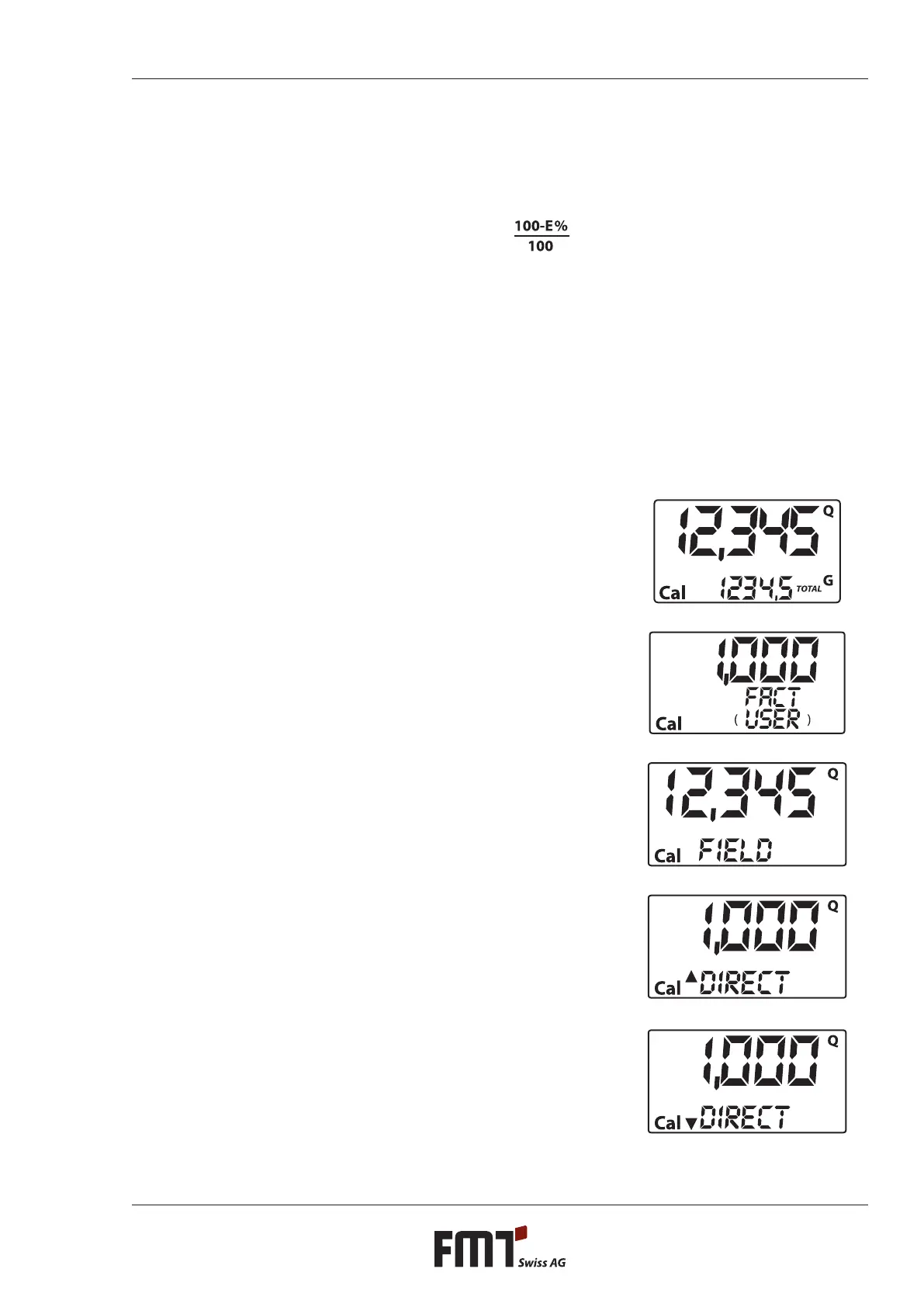

ACTION DISPLAY

1 NONE

Meter is in default standby mode, not counting.

2 PRESS TOTAL SEVERAL SECS

Meter changes to cal mode displaying valid K Factor

instead of partial volume. „FACT“ or „USER“ indicate

whether valid calibration factor is Factory K Factor or User

K Factor.

3 PRESS RESET SEVERAL SECS

Meter shows „TOTAL“ display -> resettable total register

displays zeroes. Meter is now ready for simulated operation

calibration.

4 PRESS RESET SEVERAL SECS

Changing valid K Factor directly: Display shows „Direct“plus

valid K Factor. There‘s an arrow bottom left of display (poin-

ting up or down) indicating the direction of changing USER

K FACTOR (up or down) to carry out actions 5 or 6.

5 PRESS RESET SHORTLY

Direction of arrow ips. This may be repeated as often as

necessary in order to set the correct direction.

Loading...

Loading...