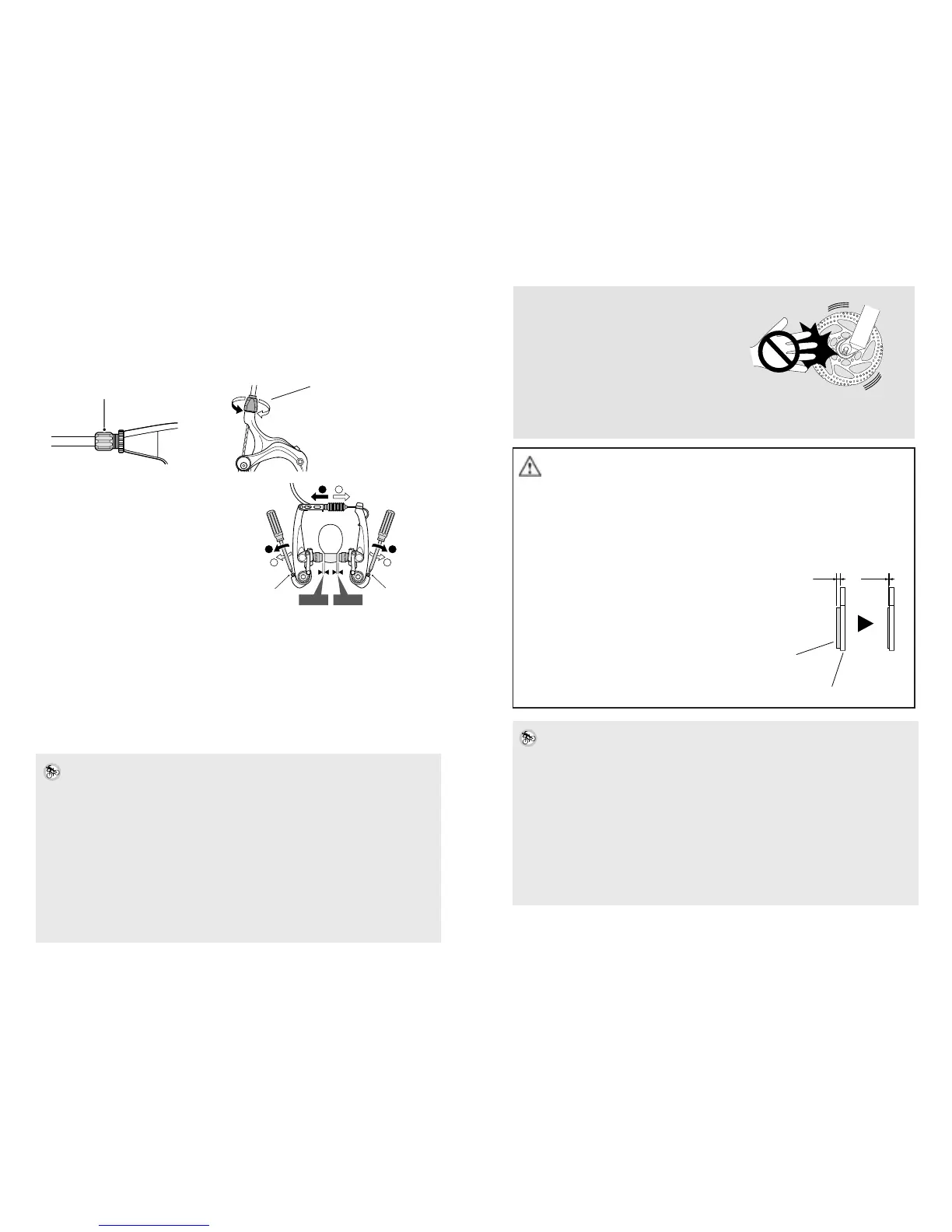

Brake block

Brake disk

2 mm 0,5 mm

Tech 33

Be particularly careful not to touch the

brake disc with your nger during instal-

lation, removal or maintenance if the disc

is rotating. If you insert your ngers in the

holes in the brake disc, you may suffer

serious injury.

The brake saddle and the disc may be hot

after braking, therefore do not touch them during

or immediately after riding, as you could burn yourself.

Before adjusting the brakes, check that the parts have cooled down sufciently.

Your bicycle may be tted with a disc brake only when appropriate xings

are present on the frame and on the fork. If in doubt, consult a dealer.

If the brake blocks have come into contact with oil or grease they must be

replaced. If the brake disc has come into contact with oil or grease it must be

cleaned, otherwise braking efciency may be strongly impaired.

Check whether or not the quick release lever is located on the right-hand side

(opposite side to the brake disc). If the quick release lever is located on the

same side as the brake disc, there is a danger that the lever and the brake disc

could impair one another

A worn, cracked or bent brake disc must be

replaced. Consult a dealer.

If the thickness of the brake block is less than

0.5 mm, it must be replaced.

Hydraulic Disc Brakes

The hydraulic oil pressure disc brake has a uid reservoir on the brake lever.

The hydraulic uid is fed to the calipers via a tube. The brake blocks are thus

pressed against the wheel rim via the brake pistons. This is a low maintenance

type of brake.

Carry out a braking test after each adjustment by pushing the bicycle

strongly whilst pulling the brake lever. Only use your bicycle when it can be

safely braked.

Check the tubes and connections for leaks each time before riding. Leaking

tubes and connections can result in brake uid leaking out of the braking

system. This can lead to reduced efciency of the brakes.

Do not use the brakes further if oil leaks out; have the appropriate repairs carried

out by a dealer without delay.

Adjusting the gap between the brake pad and the wheel rim

Turn the cable adjustment screw (adjusting bush). To increase the brake pad

gap, the adjusting screw is turned towards the inside (clockwise). To decrease

the brake pad gap, the adjusting screw is turned towards the outside

(anticlockwise). The gap between the brake block and the wheel rim should

be 1 mm. Adjusting bush Grip width adjusting screw

If necessary, adjust the spring

tension using the spring adjustment

screw so that both brake arms move

symmetrically. Subsequently, check

that the brakes work correctly

(see page 26).

If the brakes do not work correctly, of if the brake blocks are worn to the extent

that adjustment is no longer possible, have the bicycle checked and the brake

blocks replaced by a dealer.

Disc brakes

General safety advice

This type of brake is tted with a brake disc mounted on the hub and a brake

saddle on the frame or on the fork.

Have disc brakes adjusted by a dealer.

Incorrect adjustments can lead to accidents.

Carry out a braking test after each adjustment by pushing the bicycle strongly

whilst pulling the brake lever. Only use your bicycle when it can be safely braked.

Disc brakes require a ‘braking-in’ period. For braking in correctly, read the

manufacturers informations.

Braking power increases within this time. You should therefore be aware during

the braking-in period that the braking power can increase. The same applies

after replacement of the brake blocks or the disc.

If you hear noises when braking, the brake blocks may be worn down to the

wear limit. Allow the brakes to cool down and have the brake block thickness

checked or the brake blocks replaced.

Spring adjustment screw

Cable adjustment screw

Spring

adjustment

screw

Spring

adjustment

screw

1 mm 1 mm

1

2

1

2

1

2

Loading...

Loading...