10

TECHNICAL MANUAL FOR INSTALLATION, USE AND MAINTENANCE

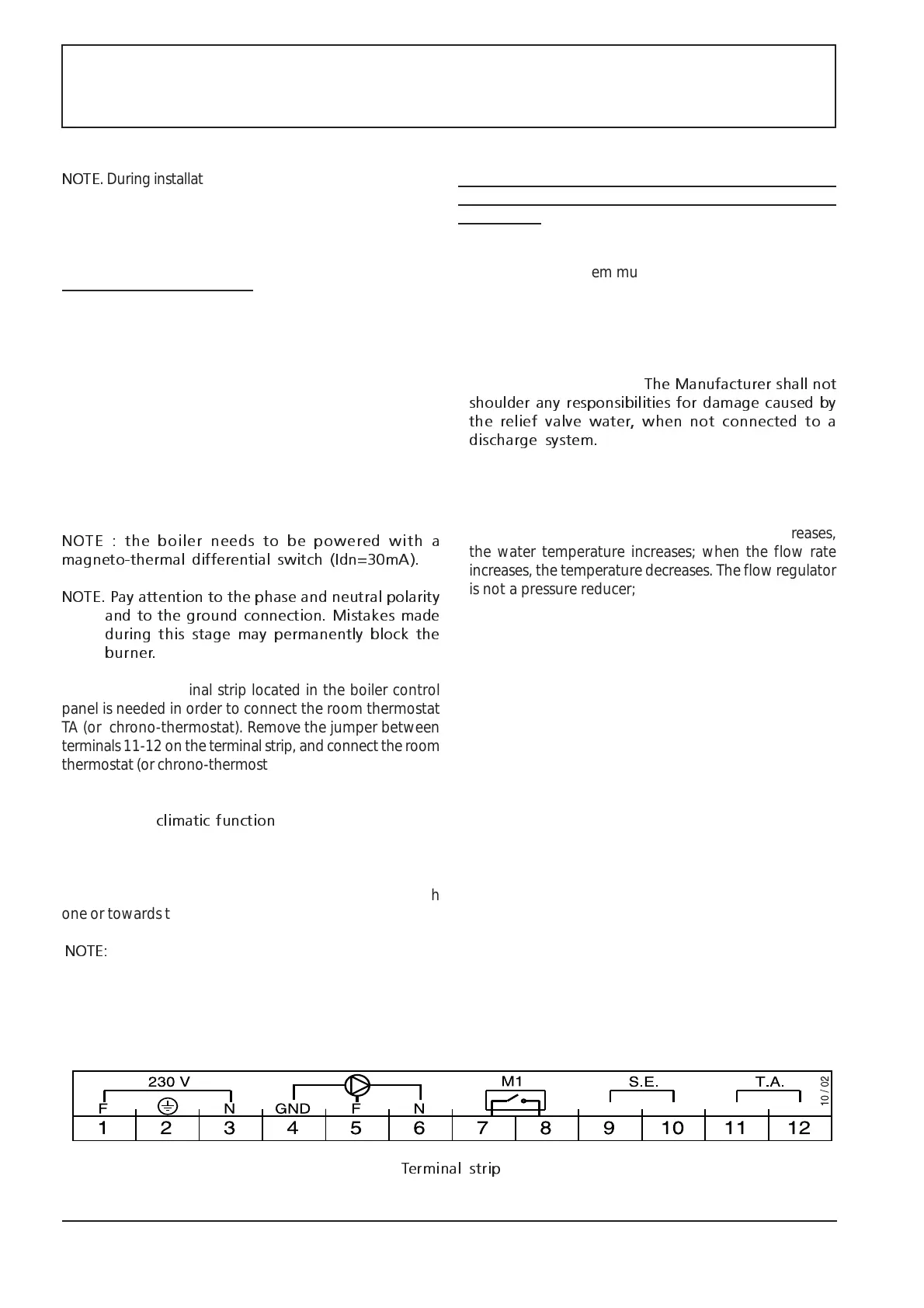

Terminal strip

NOTE

. During installation, make sure that the fumes cannot

go back into the equipment near terminal pieces or

joints between various pipe sections. When no seals

are provided, apply some silicon between two pipes.

3.4.ELECTRICAL SYSTEM.

Make sure that the available AC power matches the power

specified on the equipment rating plate (230VAC FN 50Hz).

Check the grounding line and connect it to the boiler. The

manufacturer shall not shoulder any responsibilities for

damage caused by lack of compliance with this

requirement.

De-energise the equipment and connect it to the electrical

system. For the electrical connection, use the terminal strip

located in the control panel and pay attention to the

indicated electrical connections. Remove the shell and the

control panel cover to access the terminal strip.

NOTE : the boiler needs to be powered with a

magneto-thermal differential switch (Idn=30mA).

NOTE. Pay attention to the phase and neutral polarity

and to the ground connection. Mistakes made

during this stage may permanently block the

burner.

Access to the terminal strip located in the boiler control

panel is needed in order to connect the room thermostat

TA (or chrono-thermostat). Remove the jumper between

terminals 11-12 on the terminal strip, and connect the room

thermostat (or chrono-thermostat).

Flow water temperature is adjusted in accordance to the

outdoor one (

climatic function

). In order to do so, it is

necessary to mount an outdoor probe (SE), available as

optional an option. Use connector 9-10 on the connecting

strip to connect the probe. Place it on the outside, north

wall of the building, do not absolutely place it on the south

one or towards the sun.

NOTE:

separate electric cables from power and signal ones

(TA, SE) and install them inside separates pipes.

3.5.INFORMATION TO BE RESPECTED BEFORE AND

DURING THE INSTALLATION OF THE EQUIPMENT ON

THE WALL.

- The heating system, and radiators in particular, and the

sanitary water system must be thoroughly washed with

water and a detergent-degreaser;

- Make sure the external systems are connected to the

correct boiler pipes. Ensure that all pipe connections are

correct.

- The relief valve inside the boiler must be connected to a

dedicated discharge pipe.

The Manufacturer shall not

shoulder any responsibilities for damage caused by

the relief valve water, when not connected to a

discharge system.

- When the equipment is installed under the heating system

units, on-off valves should be installed between the system

and the boiler, thus facilitating maintenance activities.

- The sanitary water flow rate must be adjusted (on the

flow meter, no.19 Fig.7): when the flow rate decreases,

the water temperature increases; when the flow rate

increases, the temperature decreases. The flow regulator

is not a pressure reducer; therefore, if the water system

pressure is too high, external pressure reducers must be

installed.

- Make sure that the free space and distances

recommended in this manual are respected, to facilitate

maintenance activities.

- Make sure that the fume discharge pipe, the chimney

and carburant air supply system are clean and efficient.

- With reference to forced-flow equipment, make sure that

no other fume discharge pipes are connected to the

chimney, with the only exception of chimneys for sealed-

chamber boilers.

- Make sure that condensation and rain water in the fume

and air pipes are collected and discharged and do not

reach the boiler.

- Connect the air intake and fume discharge pipes; make

sure that they are stable, but removable; they must not

be loose and their sealing over time must be guaranteed.

Loading...

Loading...