12

TECHNICAL MANUAL FOR INSTALLATION, USE AND MAINTENANCE

Q 02'(//2 23(5$7,216

1 ER Remove the front panel of the sealed chamber by loosening its screws.

1 E --

2 ER Remove the combustion chamber front panel.

2 E --

3 E, ER Remove the burner assembly from nozze-holder manifold.

4 E, ER Replace tha nozzles and copper seals with the parts included in the kit.

5 E,ER Re-install the burner.

Q

*DVYDOYH

23(5$7,216

6

HW, SIT

Valid only in countries where the network gas is supplyed at two pressures: install or remove the

diaphragm located between the discharge pipe and the gas valve (it is included in the kit, when

needed).

7

HW, SIT

Select the gas type on the modulation card by moving the jumper J7 (Fig.8)

8

HW, SIT

Remove the modulator cover

9

HW, SIT

Loosen the plug from the gas valve pressure inlet and check the incoming pressure with a

pressure gauge (see table below). Check the values when the boiler is working.

10

HW, SIT

Re-install the plug on the pressure inlet, open the gas valve outlet and connect the pressure

gauge to it.

11

HW, SIT

Turn the screw/adjustment nut counter-clockwise by 2 revs; turn the electrical system and the

heating system on; the flame on the main burner lights.

12

SIT

Check the pressure gauge value and adjust the

PD[ JDV SUHVVXUH

screw; this value

corresponds to the max. burner power (see table).

13

HW, SIT

Disconnect the modulator and adjust the

PLQ JDVSUHVVXUH

by turning the corresponding screw

(see table)

14

HW

Press the modulator tip and adjust the

PD[JDVSUHVVXUH

screw; this value corresponds to the

max. burner power (see table).

15

HW, SIT

Re-connect the modulator and check the set pressure values.

16

HW, SIT

Re-install the cap and seal the adjustment screws (e.g. with a drop of paint).

17

HW, SIT

2QWKH PRGXODW LRQF D UG

move the jumper J16 (Fig.4) to enable the parameter change mode

and follow the instructions provided under section 3.6.

18

HW, SIT

Disconnect the pressure gauge and place the plug on the pressure outlet.

19

HW, SIT

Place the METHANE (N.G.) or L.P.G. stickers near the gas valve and rating plate.

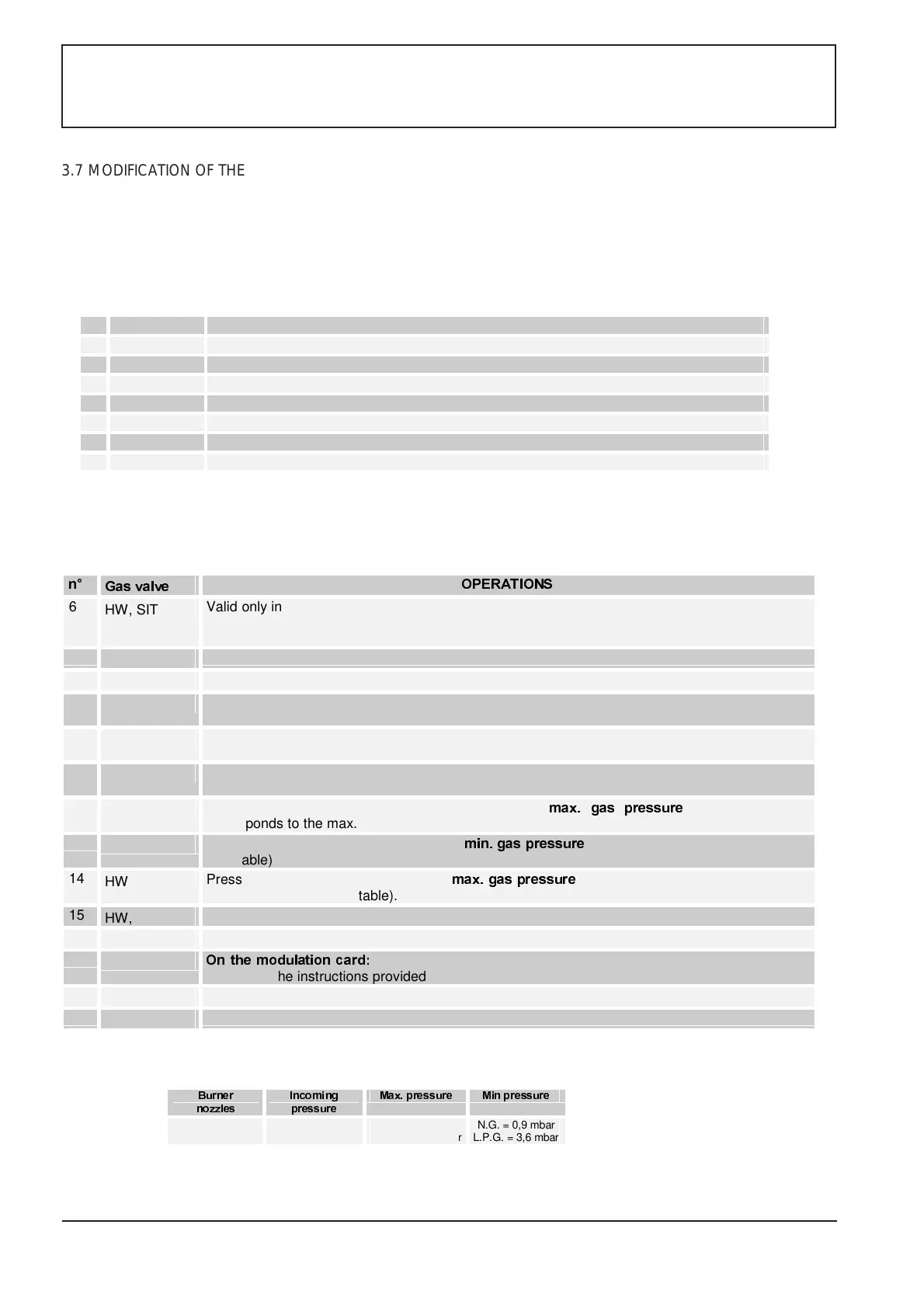

%XUQHU

QR]]OHV

,QFRPLQJ

SUHVVXUH

0D[SUHVVXUH 0LQSUHVVXUH

N.G. = 1,30 mm

L.P.G. = 0,75 mm

N.G. = 20,0 mbar

L.P.G.= 37,0 mbar

N.G. = 10,0 mbar

L.P.G. = 35,0 mbar

N.G. = 0,9 mbar

L.P.G. = 3,6 mbar

3.7 MODIFICATION OF THE BOILER PRESET GAS

This modification must be carried out ONLY by the Service Centre or authorised technicians using the components

included in the special kit.

The following procedure can be adopted when setting the boiler for LPG (with the LPG kit) or METHANE (with the

METHANE kit).

The following operations differ in accordance to the gas valve (HW=Honeywell; SIT= SIT La Precisa)

Loading...

Loading...