6

TECHNICAL MANUAL FOR INSTALLATION, USE AND MAINTENANCE

wall

boiler

3.2 WATER AND COMBUSTIBLE SYSTEM

The equipment has been designed for the type of

combustible gas specified on the plate located inside the

shell. Make sure that the available gas type and the gas

specified on the equipment match.

The combustible supply piping and the control system must

be perfectly sealed and their sections must be suitable for

the equipment capacity.

If L.P.G. is supplied, make sure that the second-stage

pressure reducer located on the tank-boiler line has a min.

capacity of 4 kg/h and 37 mbar (column of water 370)

outlet pressure adjustment.

The original gas preset of the boiler can be changed by

replacing the gas nozzles and re-calibrating the gas valve

minimum pressure.

This operation must be carried out by

qualified

technicians

: contact the authorised Service Centre.

The Service Centre must verify the correct operation of

the equipment and officially validate the guarantee

certificate within 8 days from installation.

For newly-designed water systems, Fig. 1 shows the piping

layout when looking at the wall.

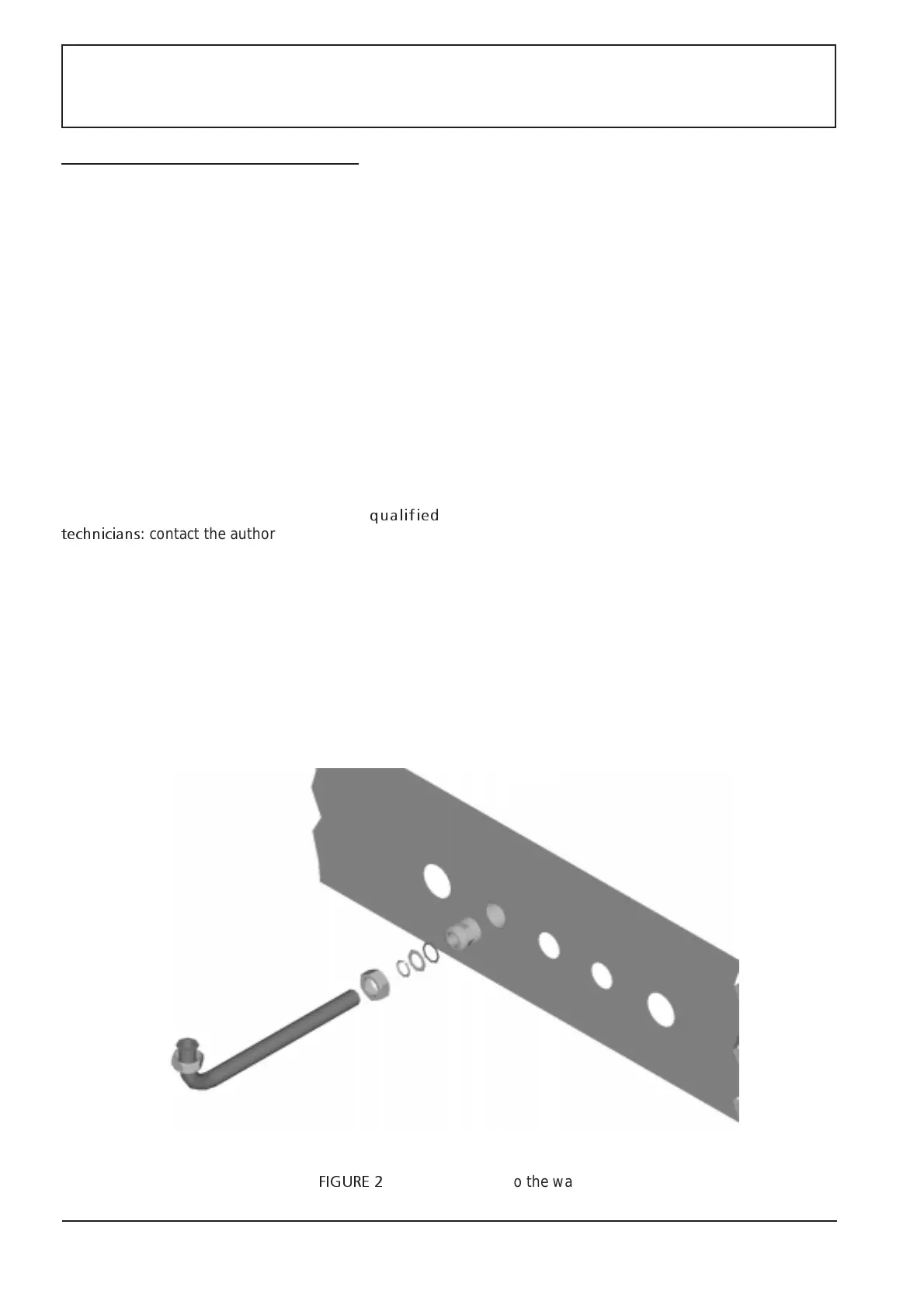

Fig. 2 shows how to connect pipes to the wall.

Place the wall mounting jig (delivered with the boiler) on

the wall to define the correct location of screw anchors

and pipes.

The pressure of the water coming from the water system

must be kept under control and below the limit specified

on the equipment plate, on the inlet point.

Hence the need for a pressure reducing valve on the

equipment cold water pipe.

The circulation device, at speed III, is suitable for the

majority of the systems. In single-pipe or very large systems,

when the load loss is remarkable or when all radiators are

not equally supplied, the circulation of water can be

increased by installing an additional pump or replacing the

pump supplied with the boiler with an expanded circulation

device.

See fig. 3 for available head/flow rate curves of the heating

system.

The boiler is equipped with a 7 litres storage tank which is

suitable for standard heating system. Specific solutions are

needed for larger or vertical systems.

The standard equipment does not include an automatic

by-pass valve between the supply and return system.

A special automatic by-pass valve is needed when

thermostatic valves are installed on all radiators or when

local flow stopping valves are mounted.

FIGURE 2

: Pipes connection to the wall

Loading...

Loading...