8

TECHNICAL MANUAL FOR INSTALLATION, USE AND MAINTENANCE

FIGURE 5

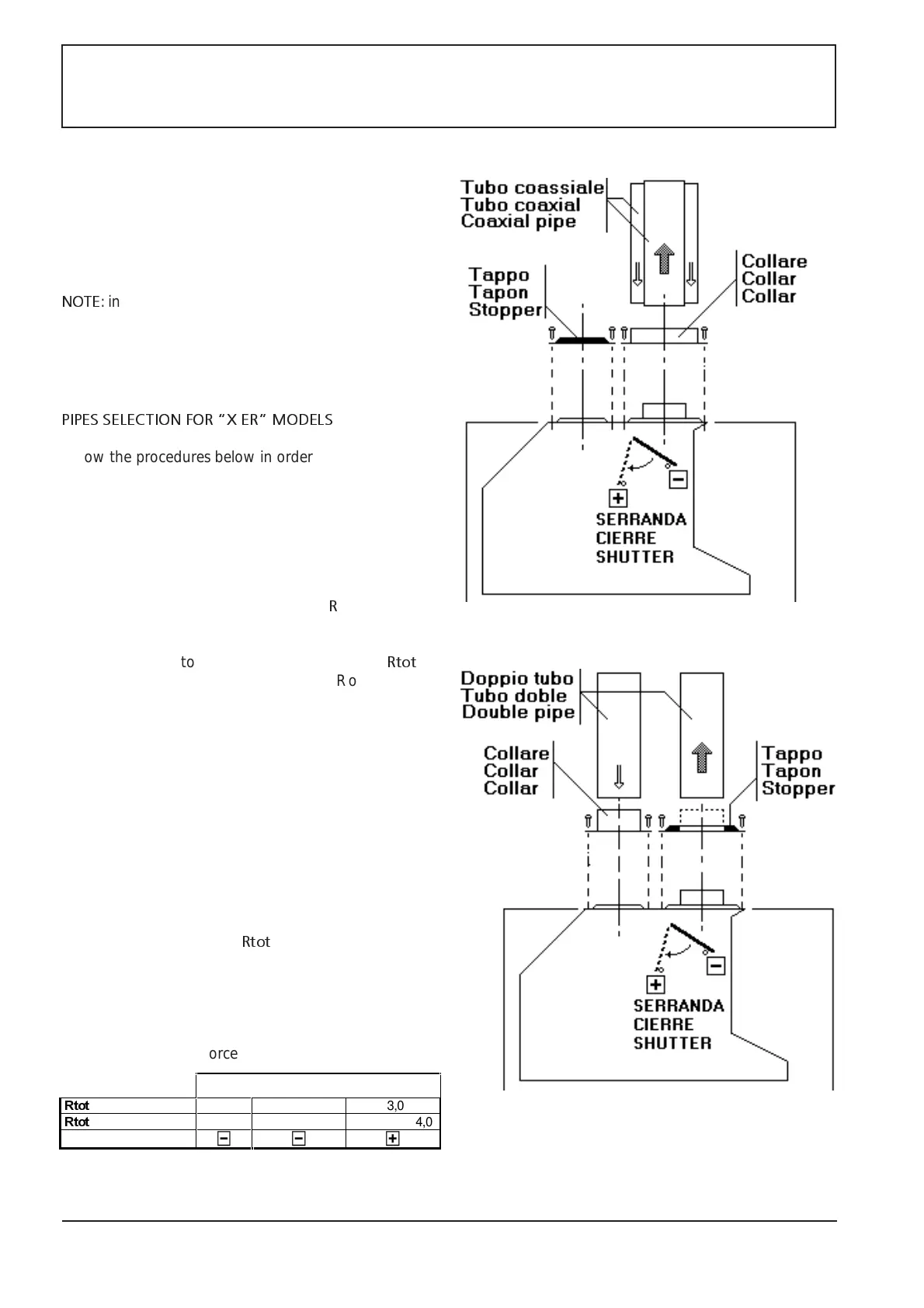

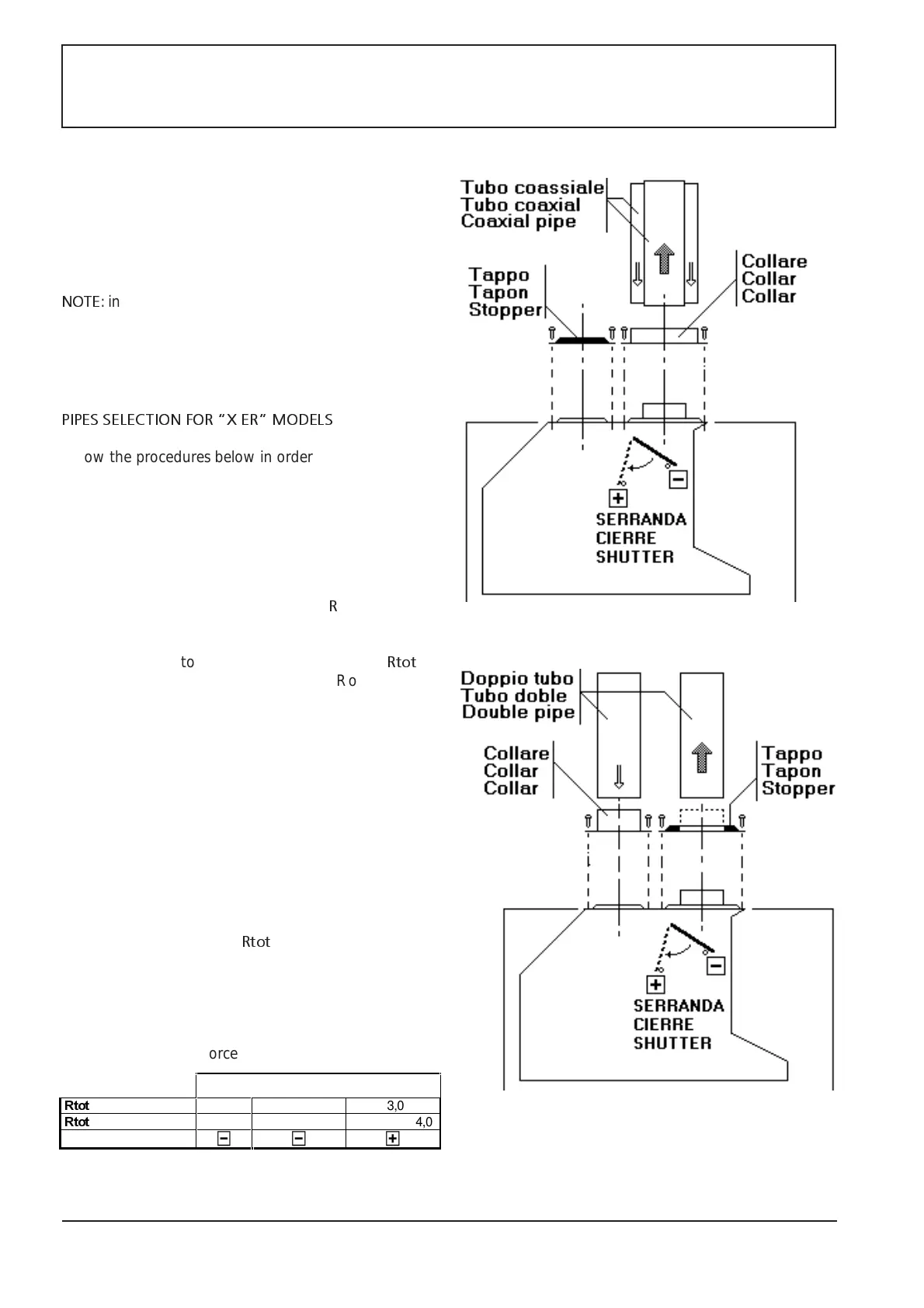

FIGURE 4

Seal chamber devices are manufactured for air intake and

flue discharge(Ø100-Ø60) coaxial systems; however it is

possible to realize some double pipe systems with separate

air intake (Ø60) and flue discharge pipes (Ø60); in order to

do so it is necessary to replace the cap and the collar

described on picture 4 with those of picture 5, these latter

are supplied with the boiler itself.

NOTE

: inside the lower sealed part of the boiler, inside the

metal casing, there is a 3mm hole which helps keeping

the pressure inside the boiler lower than the room one. In

this way, gas escapes are in-taken inside the combustion

chamber and they are not released into the room.

PIPES SELECTION FOR X ER MODELS

Follow the procedures below in order to realize a proper

pipe selection:

1) Select one of the four air-flue systems, in compliance

with current regulation, as per Fig.6 (C12, C32, C42,

C52).

2) Measure the total path length of air and flue pipes.

3) Select the air-flue pipe diameter/s and refer to Fig.6 to

define the aerodynamic resistance

R

for each pipe

section

4) Calculate the total aerodynamic resistance

Rtot

by

adding up the aerodynamic resistance R of air and flue

pipes.

5) Compare the calculated Rtot value with the max. value

specified in fig.5 for the selected air-flue system. The

calculated value should be equal to or lower than the

value specified in fig.5. Should this not be then case,

increase the pipe diameter and repeat the test starting

from point 3 above.

6) After passing the above mentioned test, establish how

to set the shutter. The cross reference table below

specifies the shutter setting depending on the type of

air-flue system (coaxial or double pipe),boiler type, total

aerodynamic resistence

Rtot

of the air-flue path.

Sealed chamber with forced draught:

;(5

5WRW

systems C12-C32 till 2,0 From 2,0 a 3,0 From 3,0 a 5,0

5WRW

systems C42-C52 till 1,0 From 1,0 a 2,0 From 2,0 a 4,0

Shutter setting

Loading...

Loading...