CONTROLS, INSTRUMENTS

..

AND

OPERATION--

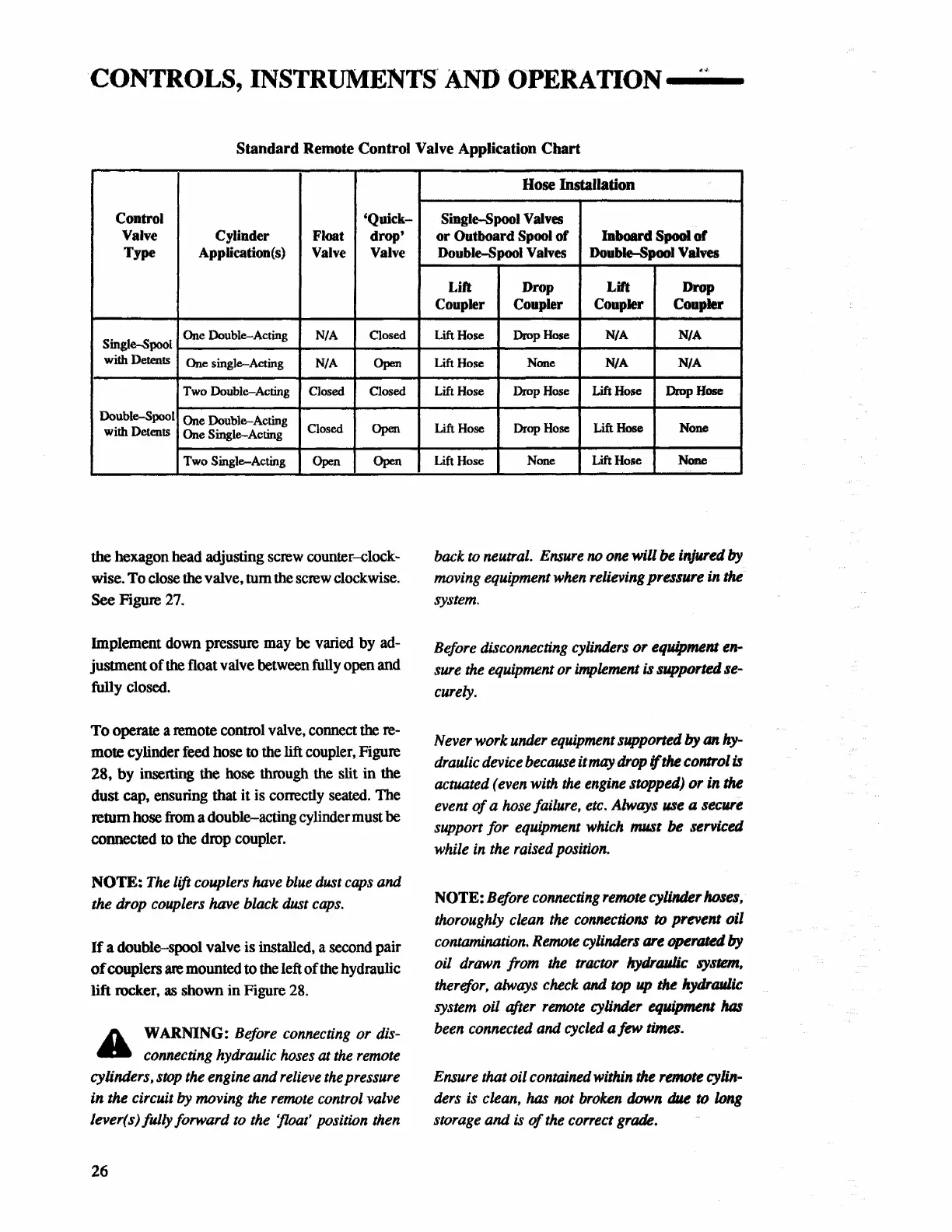

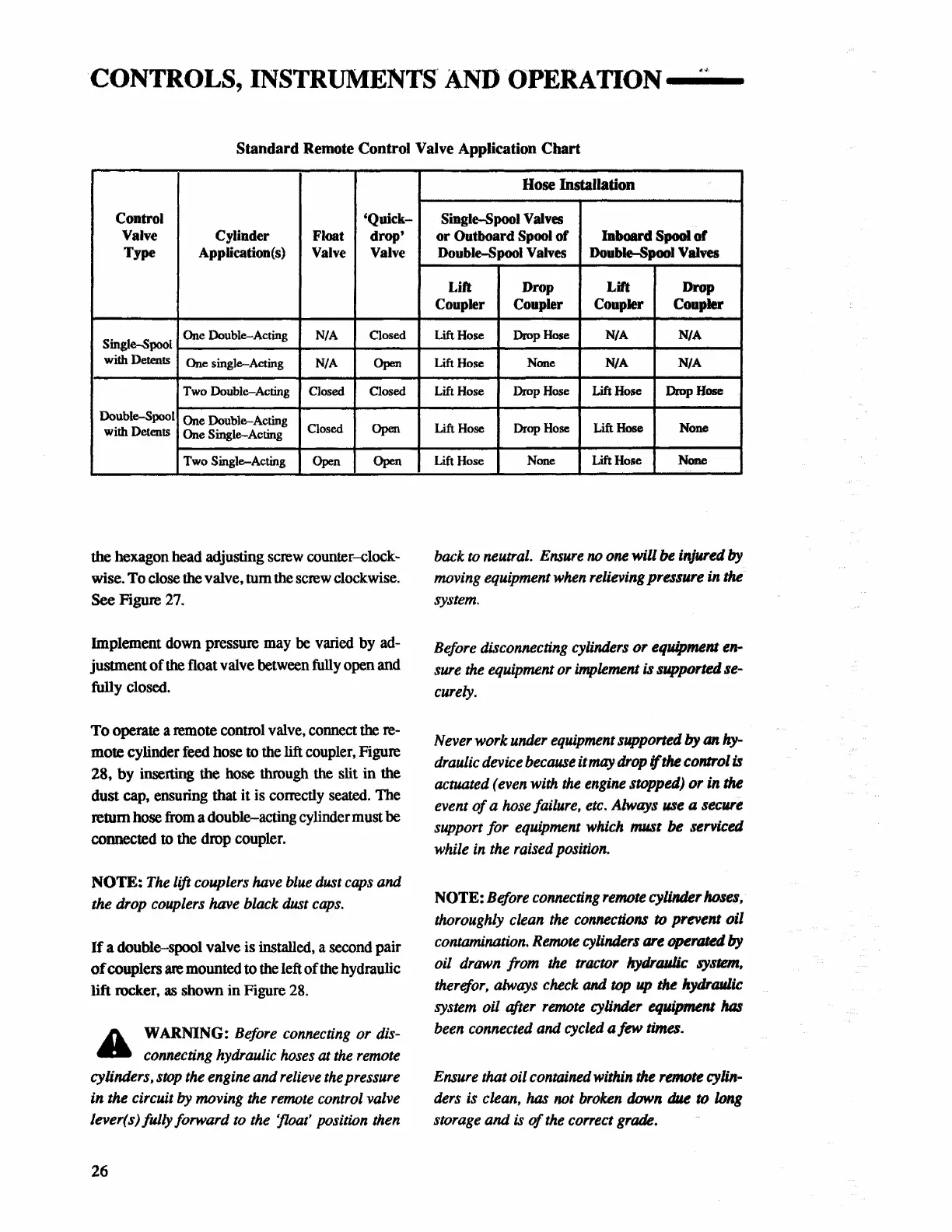

Standard

Remote Control Valve Application

Chart

Control

'Quick-

Valve Cylinder

Float

drop'

Type

Application(s)

Valve Valve

Single-Spool

One

Double-Acting

NIA

Closed

with

Detents

One

single-Acting

NIA

Open

Two

Double-Acting Closed Closed

Double-Spool

One

Double-Acting

with

Detents

One

Single-Acting

Closed Open

Two

Single-Acting

Open

Open

the hexagon head adjusting

screw

counter-clock-

wise. To close the valve, tum the

screw

clockwise.

See Figure

27.

Implement down pressure may

be

varied

by

ad-

justment

of

the

float valve between

fully

open and

fully

closed.

To operate

a

remote

control valve, connect

the

re-

mote cylinder

feed

hose

to

the

lift coupler, Figure

28, by inserting the hose through the slit in the

dust cap, ensuring

that

it is correctly

seated.

The

return hose

from

a double-acting cylinder

must

be

connected

to

the drop coupler.

NOTE:

The

lift couplers have

blue

dust

caps

and

the

drop

couplers

have black

dust

caps.

If

a double-spool valve is installed, a second pair

of

couplers

are

mounted to

the

left

of

the

hydraulic

lift rocker,

as

shown in Figure

28.

A WARNING: Before

connecti.ng

or

dis-

411a

connecting hydraulic

hoses

at

the

remote

cylinders,

stop

the

engine and

relieve

the

pressure

in the circuit

by

moving

the

remote

control

valve

lever(s) fully forward

to

the

'float' position

then

26

Hose

Installation

Single-Spool Valves

or

Outboard

Spool

of

Inboard

Spool

of

Double-Spool Valves Double-Spool Valves

Lift Drop

Lift

Drop

Coupler

Coupler Coupler

Coupler

Lift Hose

Drop Hose

N/A

N/A

Lift

Hose

None

N/A

N/A

Lift

Hose

Drop Hose

Lift

Hose

DlDpHose

Lift Hose

Drop

Hose

Lift Hose

None

Lift Hose

None

Lift

Hose

None

back

to

neutral.

Ensure

no

one

will

be

injured

by

moving equipment

when

relieving pressure in

the

system.

Before

disconnecti.ng

cylinders

or equipment

en-

sure

the

equipment

or

implement

is supported

se-

curely.

Never

work under

equipment

supported by

an

hy-

draulic

device because it

may

drop

if

the control

is

actuated

(even

with

the

engine

stopped) or in the

event

of

a

hose

failure,

etc.

Always use a secure

support for equipment

which

must be serviced

while

in

the raised

position.

NOTE: Before

connecting

remote

cylinder hoses,

thoroughly clean

the

connections

to prevent oil

contamination.

Remote

cylinders

are operated

by

oil

drawn

from

the

tractor hydraulic

system,

therefor,

always

check

and

top

up

the

hydraul.ic

system oil qfter

remote

cylinder equipment

has

been

connected and

cycled

a

few

times.

Ensure

tha.t

oil contained within the remote cylin-

ders

is

clean,

has

not

broken

down

due to

long

storage and is

of

the

correct

grade.

Loading...

Loading...