LUBRICATION

AND

MAINTENANCE-····-----

SERVICING THE DRY AIR CLEANER (continued)

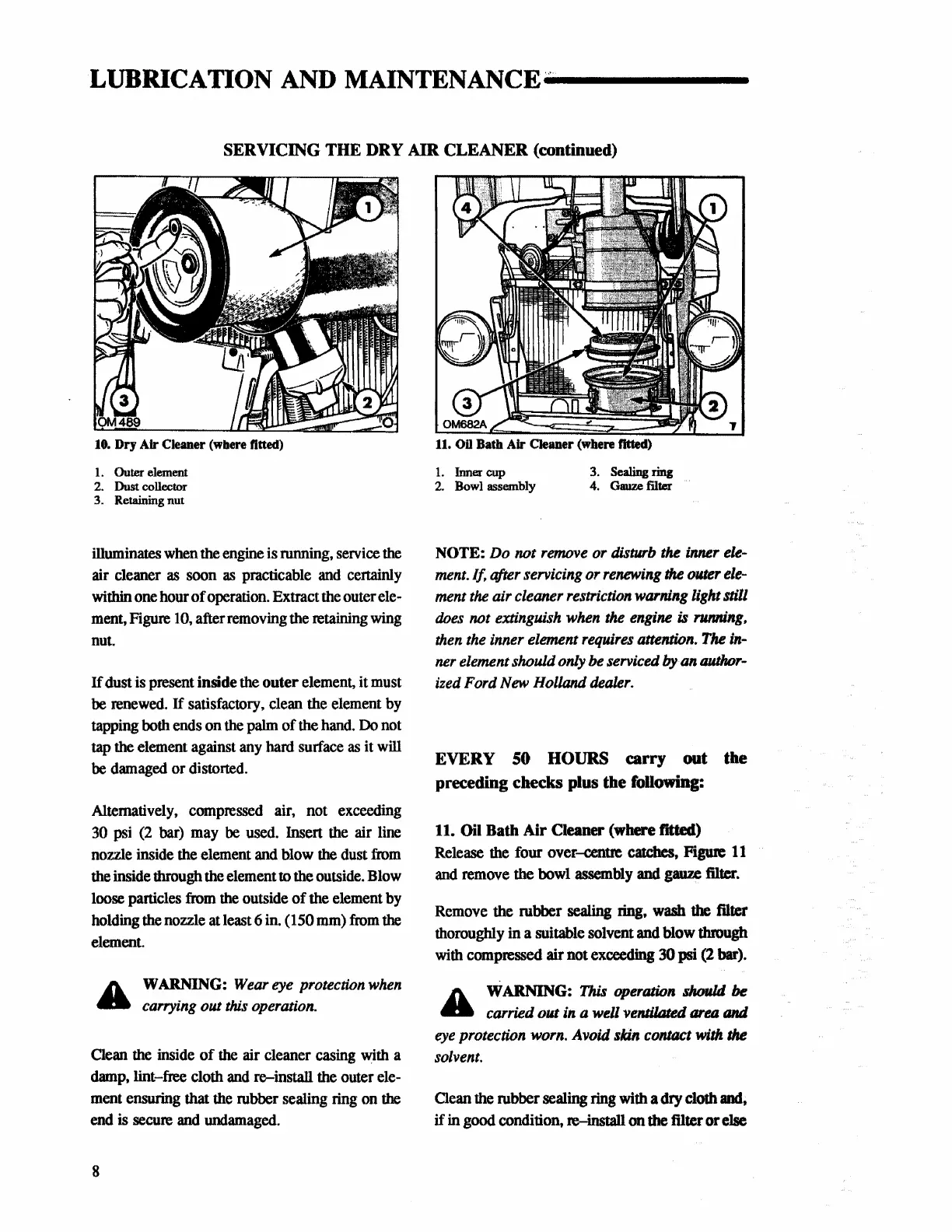

10. Dry Air Cleaner (where fitted)

1. Outer element

2.

Dust collector

3. Retaining nut

illuminates

when

the engine is running, service the

air cleaner

as

soon

as

practicable

and

certainly

within one hour

of

operation. Extract

the

outer ele-

ment, Figure

10, after removing the retaining

wing

nut.

If

dust is present inside the

outer

element, it must

be

renewed.

If satisfactory, clean the element by

tapping both ends on

the

palm

of

the

hand.

Do not

tap the element against

any

hard surface

as

it will

be

damaged or distorted.

Alternatively, compressed air, not exceeding

30

psi

(2

bar)

may

be

used. Insert the air line

nozzle inside the element

and

blow

the

dust

from

the inside through the element

to

the outside. Blow

loose particles

from

the

outside

of

the element by

holding

the

nozzle at least 6

in.

(150

mm)

from

the

element.

A.

WARNING:

Wear

eye

protection

when

411tt

carrying out

this

operation.

Clean

the

inside

of

the

air cleaner casing with a

damp,

lint-free cloth

and

re-install the outer ele-

ment ensuring

that

the

rubber sealing ring

on

the

end

is

secure and

undamaged.

8

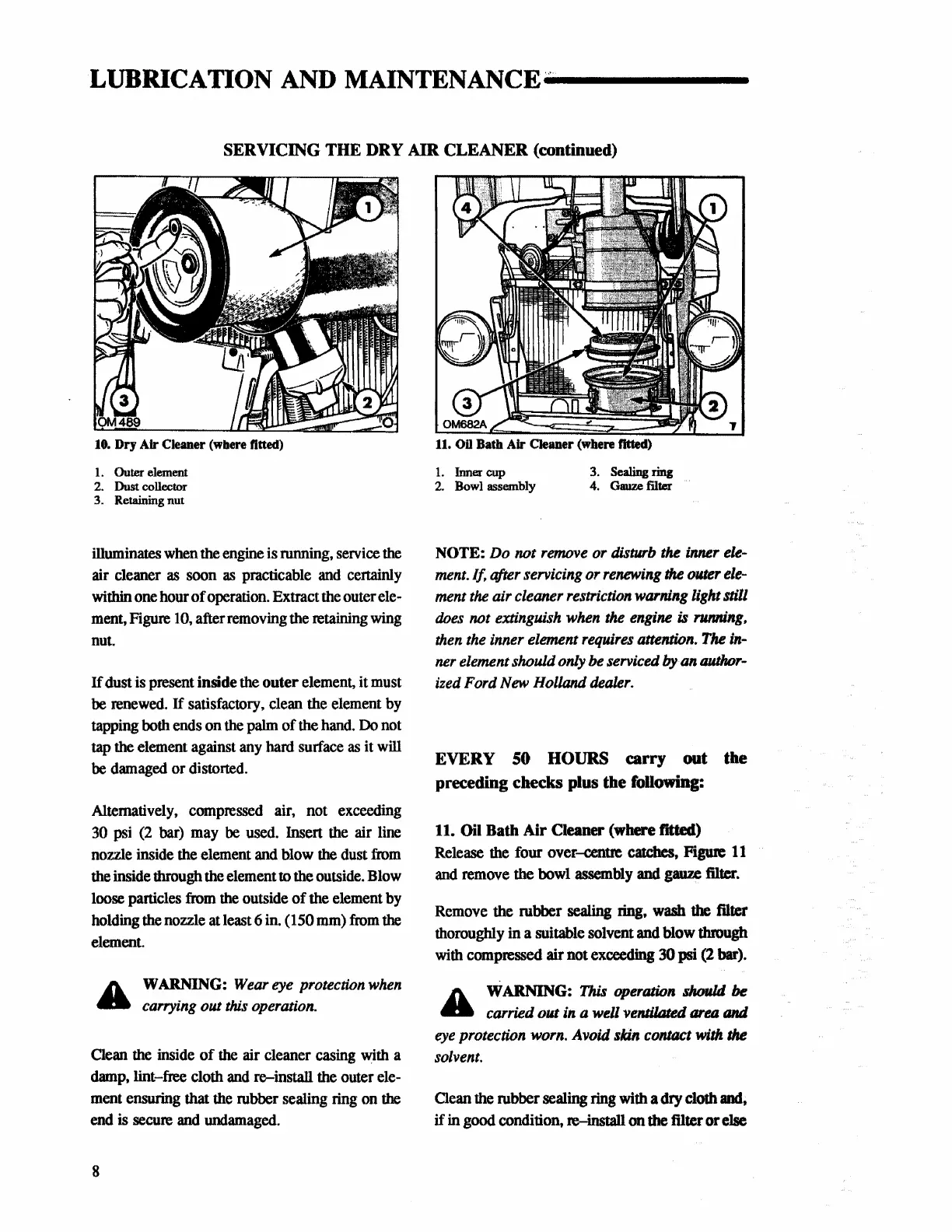

11.

Oil Bath Air Cleaner (where f'ittecl)

1.

Inner cup

3.

Sealing

ring

2.

Bowl assembly

4. Gauze

filter

NOTE:

Do not

remove

or disturb the inner

ele-

ment.

If,

qfter servicing or

renewing

the

outer

ele-

ment

the

air cleaner restriction warning light sti.ll

does

not extinguish when

the

engine is

running,

then

the

inner element

requires

attention.

The

in-

ner

element should only be serviced byan

author-

ized Ford

New

Holland

dealer.

EVERY 50 HOURS carry out the

preceding checks plus the

following:

11. Oil

Bath

Air

Cleaner

(where fitted)

Release the

four

over-centre

catches,

Figure

11

and

remove the bowl assembly

and

gauze

filter.

Remove the rubber

sealing

ring, wash the filter

thoroughly in

a suitable solvent and blow through

with

compressed

air

not exceeding 30

psi

(2 bar).

A WARNING: This operation should

be

4ll:a carried out

in

a well ventilated area

and

eye

protection worn. Avoid

sldn

contact with

the

solvent.

Oean

the rubber sealing ring with a

dry

cloth and,

if

in good condition, re-install on the filter or else

Loading...

Loading...