---------------SECTION

B

600 HOUR SERVICE (continued)

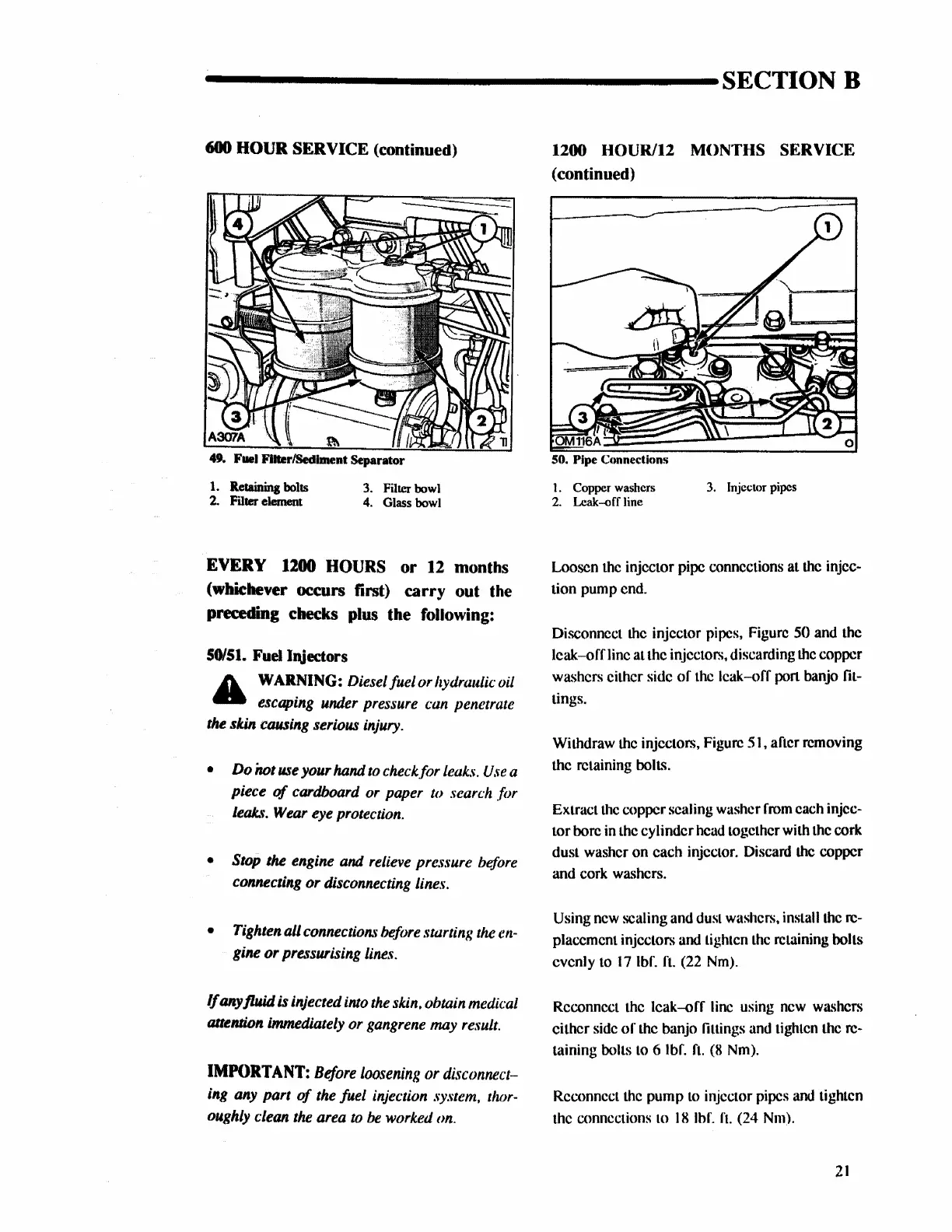

49. Fuel Fitter/Sediment Separator

1. Retaining bolts

3. Filter bowl

2. Filter element

4.

Glass

bowl

EVERY 1200 HOURS

or

12 months

(whichever occurs first)

carry

out

the

preceding checks plus

the

following:

50/51. Fuel Injectors

A WARNING: Diesel fuel or hydraulic oil

...

escaping

under

pressure

can

penetrate

the

skin causing

serious

injury.

•

Do

not

use

your

hand

to

check

for

leaks.

Use

a

piece of cardboard or paper to search for

leaks.

Wear

eye

protection.

• Stop the engine and

relieve

pressure

before

connecting

or

disconnecting lines.

• Tighten all connections before starting the

en-

gine

or

pressurising

lines.

If

any fluid is injected into

the

skin, obtain medical

attention immediately or

gangrene

may

result.

IMPORT

ANT:

Before

Loosening

or

disconnect--

ing

any

part

of

the fuel injection system,

thor-

oughly clean

the

area

to

be

worked

on.

1200 HOUR/12 MONTHS SERVICE

(continued)

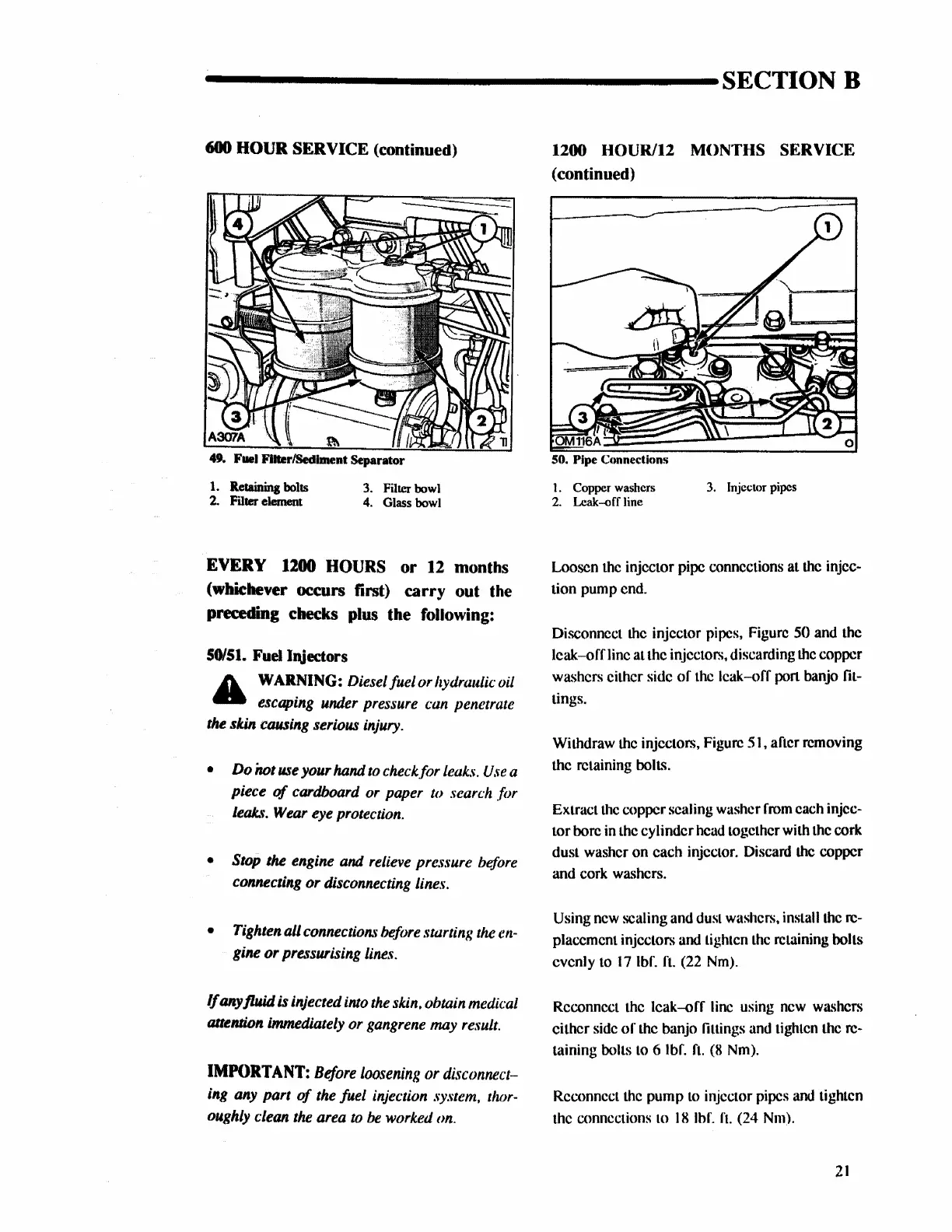

50. Pipe Connections

1.

Copper washers

3.

Injector

pipes

2. Lcak--0ff line

Loosen

the

injector pipe connections al

the

injec-

tion

pump

end.

Disconnect

the

injector pipes,

Figure

50

and

the

leak-off

line

al the injectors. discarding

the

copper

washers either side

of

the

leak-off pon

banjo

fit-

tings.

Withdraw

the

injectors,

Figure

51. after removing

the retaining bolt'\.

Extract

the

copper scaling washer

from

each injec-

tor bore

in

the

cylinder

head

together

with

the

cork

dust washer on each injector. Discard

the

copper

and cork washers.

Using

new

scaling

and

dust

washers.

install

the

re-

placement injectors

and

lighten

the

retaining bolls

evenly

to

17

lbf.

ft.

(22

Nm).

Reconnect

the

leak-off

line

using

new

washers

either

side

of

the

banjo

fillings

and

tighten

the

re-

taining bolls

lo

6 tbr.

ft.

(8

Nm).

Reconnect

the

pump

to

injector pipes

and

tighten

the

connections

to

18

lbf.

ft.

(24

Nm).

21

Loading...

Loading...