Forest Master Models: FM9DD/FM14DD/FM18DD18

Maintenance

Maintenance

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to

this manual and the engine manufacturer’s user manual for maintenance procedures.

Before performing any maintenance procedure or inspection, stop the engine, wait five minutes to allow all

parts to cool and disconnect the spark plug lead.

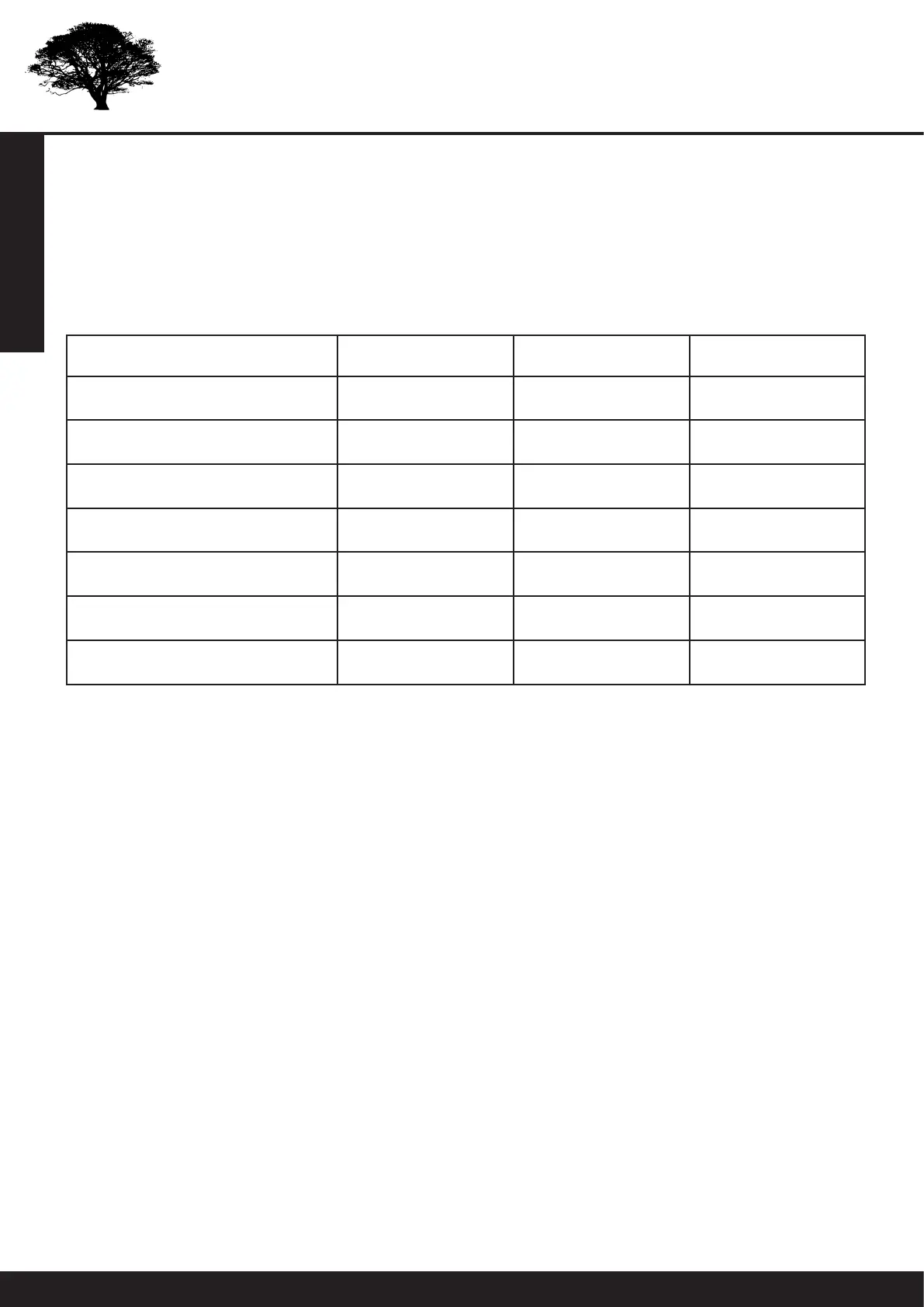

Regular Maintenance Checklist

Procedure Before Each Use Every 25 Hours Every 100 Hours

Check Engine Oil Level X

Check General Equipment Condi-

tion

X

Check Blades for Sharpness and

Wear

X

Clean Engine Exterior and Cooling X

Change Engine Oil X

Replace Air Filter X

Replace Spark Plug X

Engine Oil

Do not use the dipstick of the engine to check the oil level. Due to the conditions under which the chipper

may be used, the dipstick is not accurate enough, the engine must have the specified quantity of oil. FM9DD

600ml, FM14DD & FM18DD 1100ml. To change the oil, drain the old oil into a suitable container. Measure out

the required level of oil into a clean container, remove the filler bung and add the oil. Do not tip the chipper

up to fill with oil.

Engine/Motor Servicing

For the servicing of the petrol engine refer to the engine manufacturer’s user manual. If you need help

accessing the manual, contact Forest Master.

Replacing and Sharpening the Blades

To remove the blades for sharpening or replacement you will need an appropriate 16mm socket with NO

LEADING TAPER, as the bolt heads are shallow. If a socket with a leading taper is used, there is a possibility

of rounding the bolt head as the socket will slip. A suitable socket can be purchased on the Forest Master

website https://forest-master.com/product/hexagonal-impact-socket/.

Undo the bolt at the bottom of the feed hopper and lift the hopper upwards on the hinge to access the drum.

Loosen the bolts holding the blade to the drum and remove the blade. There are two blade positions on the

drum and both blades will need to be maintained equally.

Note: The blades are reversible so they can be turned around to use the second side before they need to be

re-sharpened.

If the blades are re-sharpened, you will need to adjust the base block at the bottom of the drum to close the

gap between the edge of the block and the knives. The base block will need to be moved inwards so that

there is a gap of around 0.25mm between the knives and the base block. Make sure the drum rotates freely by

moving it by hand using the nut on the outside of the drum.

When refitting the blades, you should use a small amount of mild thread lock to secure each bolt.

Loading...

Loading...