06

ELECTRICALS

INSTALLATION

Provide a clean, flat, well lighted installation site. Level the machine and anchor it to the floor.

Inspect the gears and drive assembly, and remove any debris that may have accumulated during

shipping.

Standard Electrical: 2HP (1.5KW)

110 Volts 1 phase, grounded power supply. Provide a sufficient 110V receptacle at the point of

operation. If a 3 phase motor is ordered install the power supply in compliance with national

electrical codes. For further information contact a certified electrician or Lockformer service dept.

(Contact information at www.Lockformer.com or tel# 1-630-964-8000)

CAPACITY

Maximum 1mm thickness (20 Gauge) black iron mild steel and Galvanized steel.

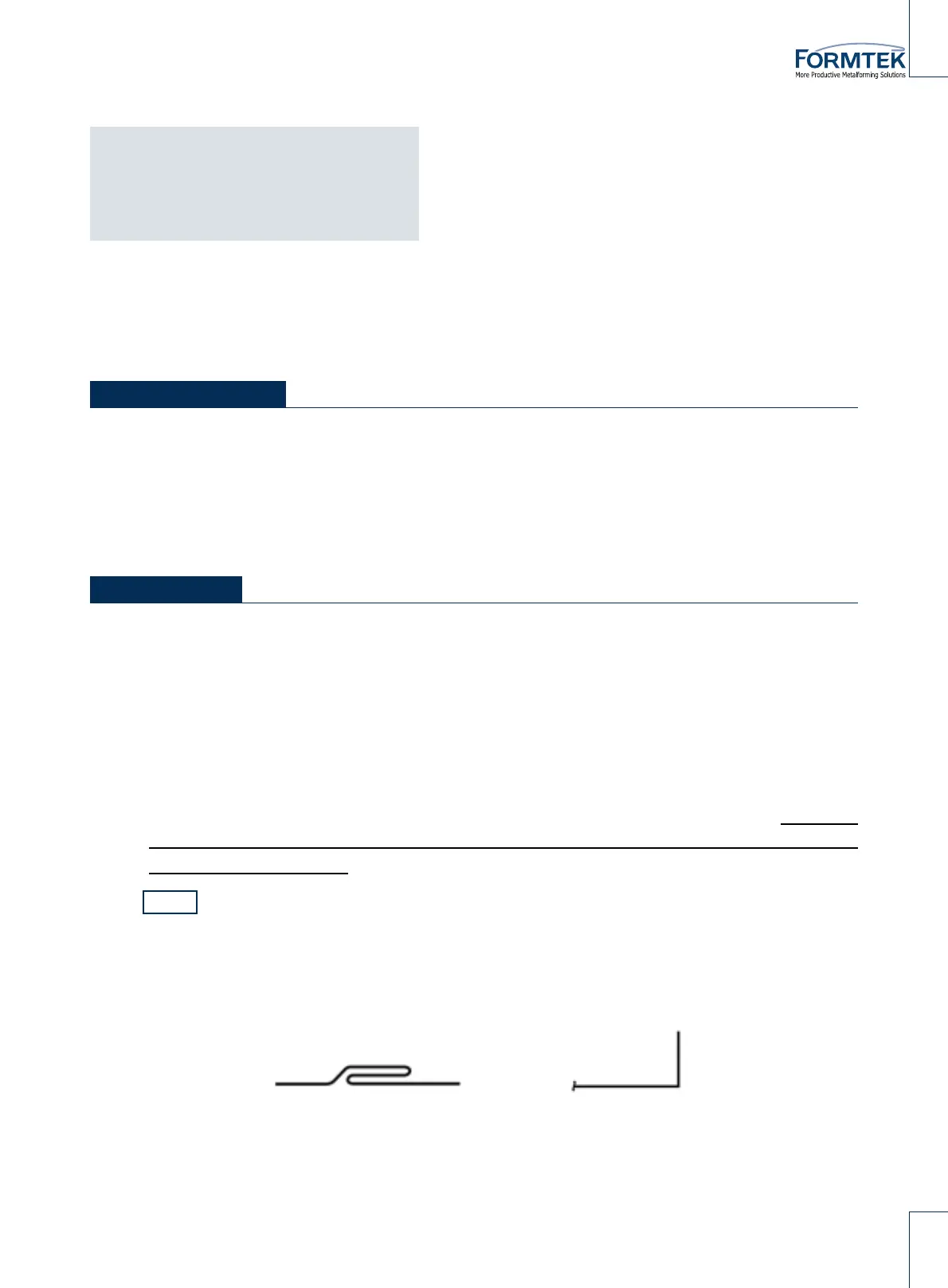

MATERIAL ALLOWANCE: = 25mm, 1”

(1) 25mm (1”), female PITTSBURGH

(2) 6mm (1/4”)90 degree (MALE)

Total amount of material (25mm Female PITTSBURGH + 6mm MALE)=31mm.

(1” Female PITTSBURGH + 1/4” MALE)= 1-1/4”

This allowance to be added for the seam formed sections for calculation of sheet sizes. The above

dimensions can be modified by moving the entrance gauge position to suit the requirements of a

specific project or material.

Note: The machine has been tested and adjusted at the factory on 0.6mm (26ga) through 1mm

(20 ga) thickness material and as delivered is ready for normal operation.

Female PITTSBURGH 90 degree (MALE)

Loading...

Loading...