OPERATION

Priming the Pump

6

OPERATION

Priming the Pump

NOTE: It may be necessary to remove the coupling cover guards during priming. Refer to “Mainte-

nance” on page 7.

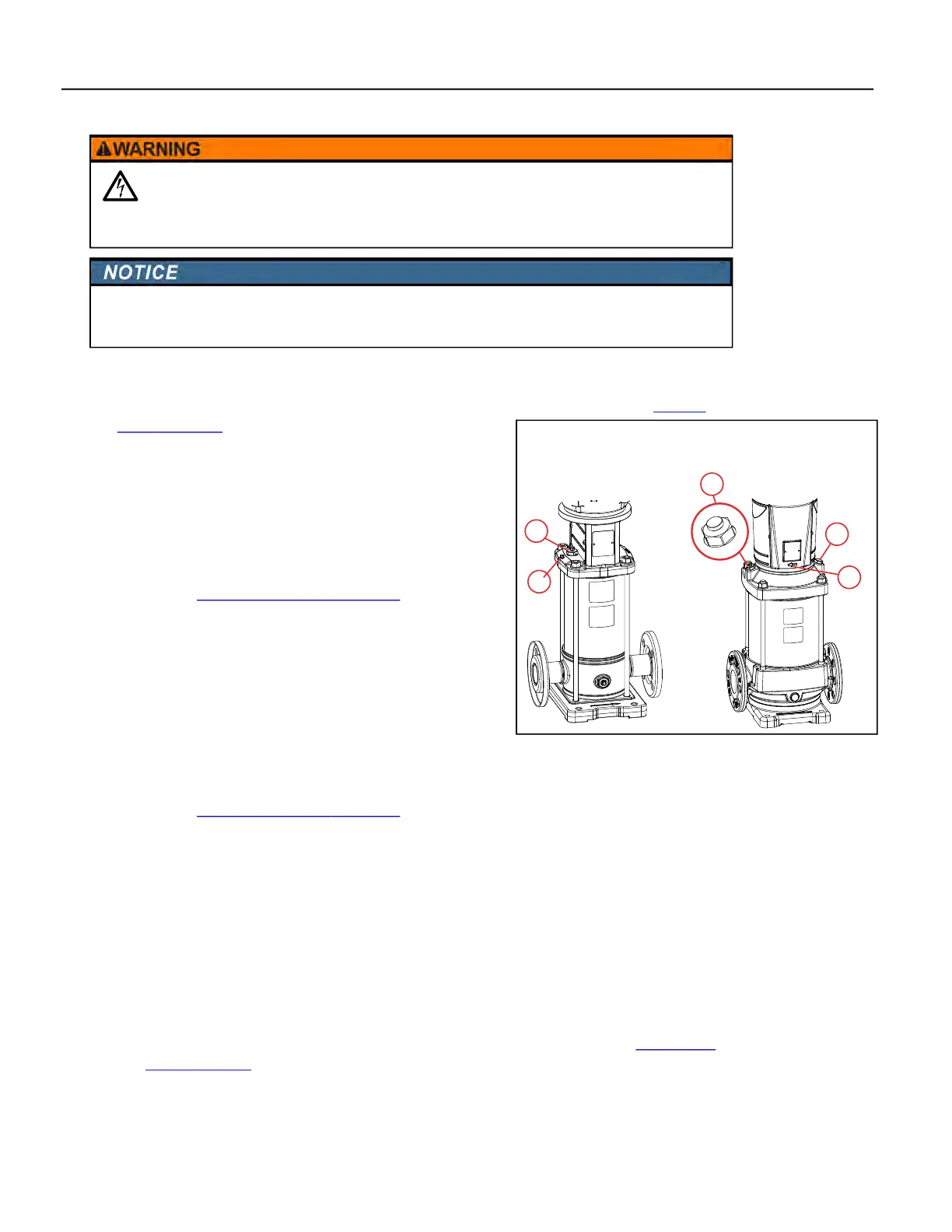

Flooded Suction Installation

1. Ensure the discharge line gate valve is closed.

2. Loosen the needle pin on the filling plug.

3. Open the inlet discharge gate valve.

4. Allow water to enter until it comes out the filling plug.

5. Tighten the needle pin on the filling plug.

• Refer to “

Torque Specifications” on page 3.

Suction Lift Installation

NOTE: Ensure the suction gate valve remains open.

1. Close the discharge gate valve.

2. Remove the filling plug(s).

3. Fill the pump and suction line with water.

4. Rotate motor shaft to let air in casing escape, following the pump rotation arrow.

5. Refill the pump and suction line with water.

6. Reattach the filling plug(s).

• Refer to “

Torque Specifications” on page 3.

Starting the Pump

1. Check pump rotation.

• If direction is wrong, interchange any two of three wires either at the motor or starter.

2. Close all system outlets.

3. Slightly open one system outlet to allow excess air to bleed out of the system.

4. Start the pump.

5. Gradually open the discharge valve halfway.

• Several starting attempts may be necessary to expel all air from the pump and suction lines.

• After initial start-up, pump operation ought to be smooth and quiet.

• If water is not delivered within seconds, stop the motor and prime again. Refer to “

Priming the

Pump” on page 6.

6. Once the pump is fully functioning, completely open the discharge valve and system outlets.

Risk of severe injury or death by electrical shock, high temperatures, or

pressurized fluids.

• To minimize risk of electrical shock, disconnect power before working on or around the system.

• Do not continuously run pump against closed discharge. Release all system pressure before working on any component.

Risk of damage to pump or other equipment.

• Do not let the unit run dry (without liquid). It is designed to be cooled by pumping fluid. The seal may be damaged and the

motor may fail if the pump is allowed to run dry.

NEMA 254/256, 284/286,

324/326, 364/365

NEMA 56, 182/184,

213/215

Loading...

Loading...