MODEL: PFL618BR MODEL: PFL618BR

08 09

Lubricate tool only with specified

lubricants.

CAUTION:

MAINTENANCE

LUBRICATION

Frequent, but not excessive, lubrication is required

for best performance. Oil for the tool added through

the air line connection add will lubricate the internal

parts. Do not detergent oil or additives as these

lubricants will cause accelerated wear to the seals

and bumpers in the tool, resulting in poor tool

performance and frequent tool maintenance.

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from

various types of commercial solvents and maybe

damaged by their use. Use clean cloths to remove

dirt, dust , oil, grease, etc.

CLEA INGN

Any time inspection, maintenance, and

cleaning are done:

◆Disconnect the tool from the air

Empty the magazine completely.

source.

◆

WARNING:

!

Do not at any time let brake fluids,

gasoline, petroleum-based products,

penetration oils, ect. come in contact

with plastic parts. Chemicals can damage,

weaken or destroy plastic which may

result in serious personal injury.

WARNING:

!

Do not store tools in a cold weather

environment to prevent frost or ice

formation on the tools' operating valves

and mechanisms that could cause tool

failure.

CAUTION:

COLD WEATHER OPERATION

For cold weather operation, near and below freezing,

the moisture in the air line may freeze and prevent

tool operation. We recommend the use of air tool

lubricant or permanent antifreeze (ethylene glycol)

as a cold weather lubricant.

Drive Guide(H)

Bolts(I)

TROUBLESHOOTING

Air leaking in head cap. ⒈Loose screws.

⒉Worn or damaged O-rings or seals.

⒈Tighten screws.

Install overhaul kit.⒉

Lack of power.

Slow to cycle.

⒈Tool is too dry.

Air pressure too low.

Exhaust blocked.

⒉

⒊

⒈Add about 2-3 drops of

lubrication into the air connector.

⒉Make sure the air compressor

is set between 70psi and 110psi.

Clean exhaust channel.⒊

Not shooting fasteners .

⒈Damaged pusher spring.

Wrong size of fasteners.⒉

⒈Replace spring.

⒉Use 1/2" crown staples or

1-1/2" to 2" nails.

⒈Fix the drive channel.

Replace the piston.

Remove the bent fasteners,

replace with the 1/2" crown

staples or 1-1/2" to 2" nails.

Clean magazine.

Tighten screws.

Verify that fasteners are the

correct size.

⒉

⒊

⒋

⒌

⒍

⒈Drive channel is worn.

Piston is broken or worn.

Bent fasteners.

Dirty magazine.

Loose magazine.

Wrong fasteners.

⒉

⒊

⒋

⒌

⒍

Fasteners are

jammed in the tool

frequently.

Use only Freeman Authorized Repair Parts. For questions please call 1-888-669-5672 or visit

our website at http://www.freemantools.com

WARNING:

!

WEARING PARTS

Repair parts can be ordered from our website: http://www.freemantools.com

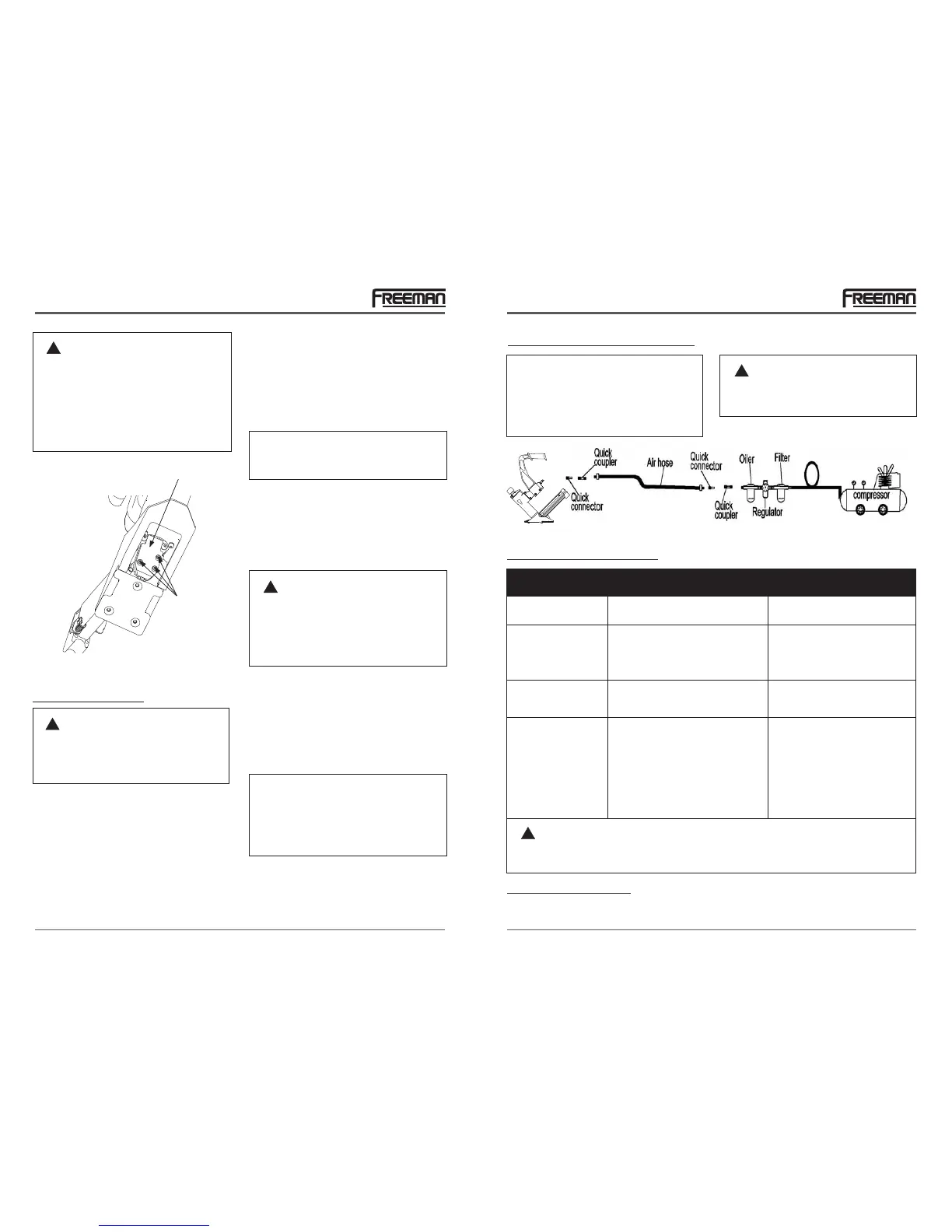

RECOMMENDED HOOKUP

The air compressor must be able to

maintain a minimum of 70psi when the

tool is being used. An inadequate air

supply can cause a loss of power and

inconsistent driving.

CAUTION:

Disconnect the tool from the air source

whenever clearing a jam. After

disconnecting the tool from the air

compressor, there should still be enough

air pressure to fire the tool. After the air

hose is disconnected, always fire the tool

into scrap wood repeatedly to make sure

all of the compressed air is expended.

WARNING:

!

Each tool is packed with an anti-dust cap on the air

connector, check it after unpacking. Keep the anti-

dust cap to cover the air connector when the tool is

not in use to prevent the dust.

ANTI-DUST CAP

Do not connect with an air compressor

which can potentially exceed 200psi. As

tool may burst, possibly causing injury.

WARNING:

!

HTTP://WWW FREEMANTOOLS COM 1-888-669-5672.. HTTP://WWW FREEMANTOOLS COM 1-888-669-5672..

PROBLEMS POSSIBLE CAUSES CORRECTION ACTIONS

Loading...

Loading...