non-purging seal, or tap the driveshaft or yoke

with a plastic or rawhide mallet on the side oppo-

site the dry seal, while continuing to lubricate. If

grease still does not appear, loosen the cap-

screws at the bearing with the dry seal, to relieve

seal tension. Lubricate the U-joint until new

grease is seen at the seal, then tighten the cap-

screws to the correct torque specifications. If the

bearing will not take grease, replace the U-joint;

see Group 41 of the 108SD and 114SD Work-

shop Manual.

6. Check the purged grease. If it appears rusty,

gritty, or burned, replace the U-joint.

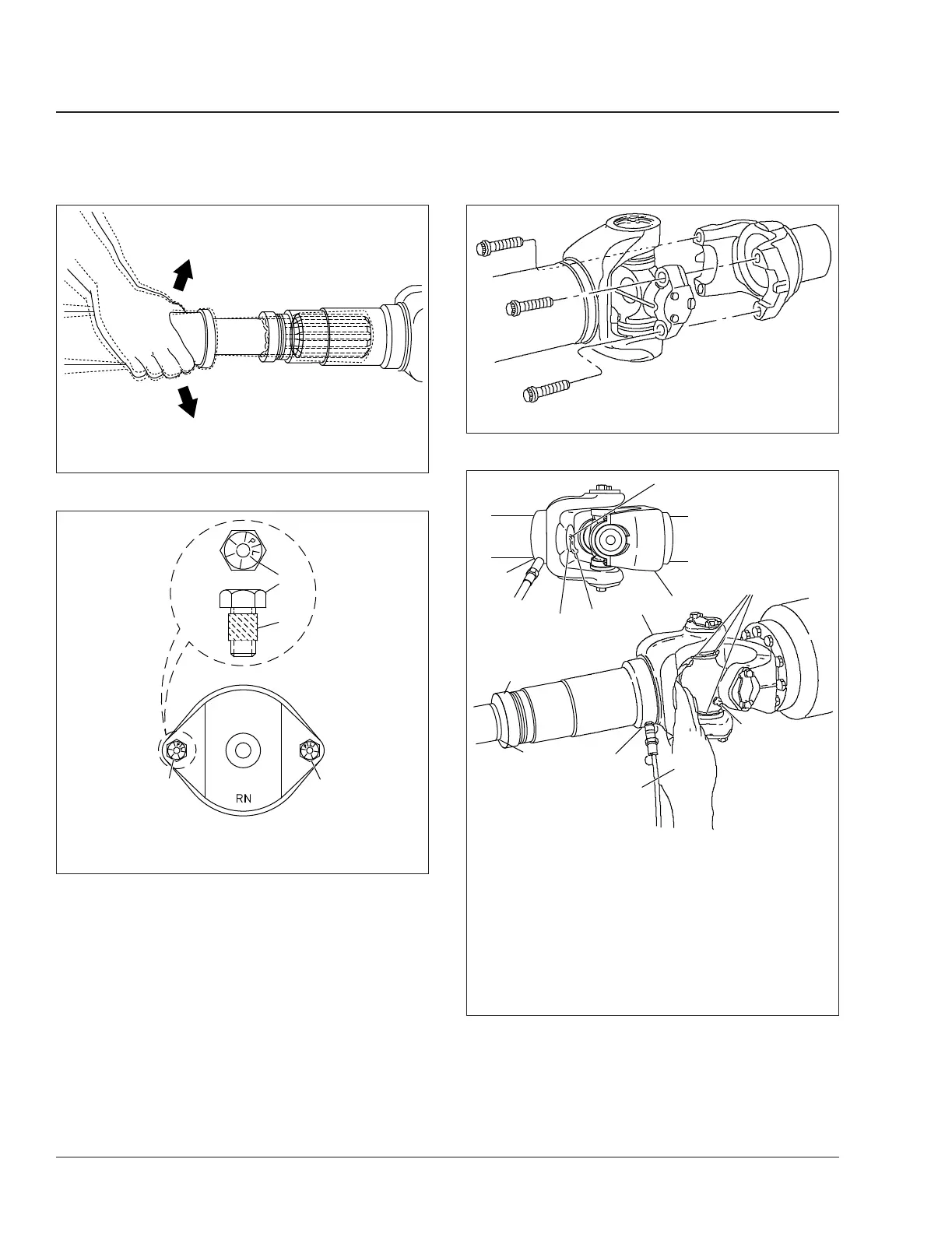

f410012a10/06/2016

Attempt to move the sleeve-yoke and splined shaft back

and forth.

Fig. 3, Slip Joint Spline Wear Checking

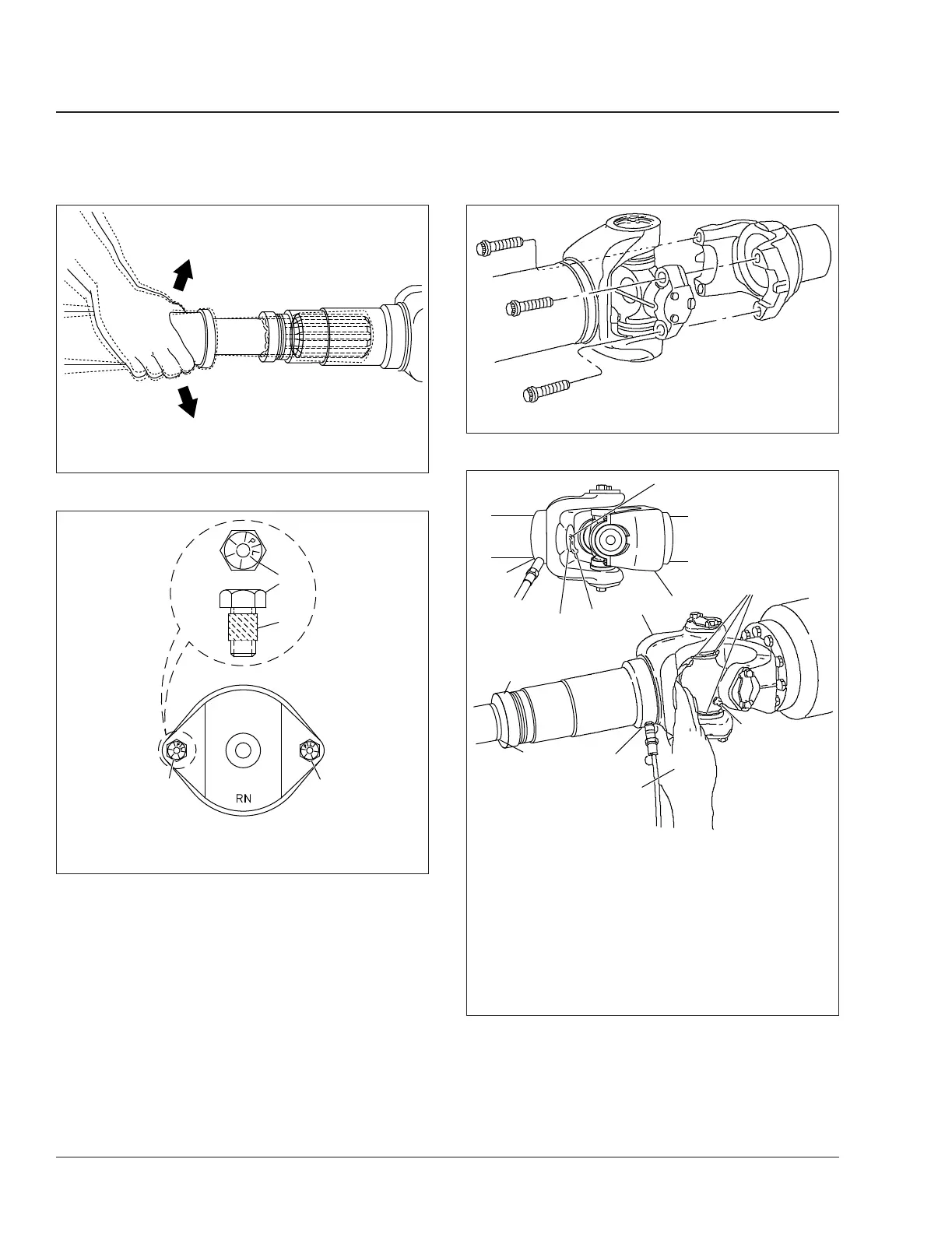

f410155a10/06/2016

1

1

1

2

M

E

R

I

T

O

R

1. Self-Locking Capscrew

2. Adhesive Band

Fig. 4, Meritor U-Joint Fasteners for Full-Round Yokes

f41018210/06/2016

Fig. 5, Meritor RPL Series U-Joint

f410050a10/07/2016

1

1

2

3

3

3

4

5

6

7

8

A

A. After grease appears, cover the pressure-relief hole

while continuing to lubricate.

1. Slip Joint Grease Fitting (with grease gun attached)

2. Yoke Plug

3. Grease

4. Half-Round Yoke

5. Yoke Plug Pressure-Relief Hole

6. Slip Joint Seal

7. Full-Round Yoke

8. U-Joint Grease Fitting

Fig. 6, Slip Joint and U-Joint Lubrication

Driveline41

108SD and 114SD Maintenance Manual, September 201541/4

Loading...

Loading...