grease, NLGI Grade 2 (8% 12-hydroxy lithium stear-

ate grease), until new grease is seen at the bushing

grease seal opposite the fittings. The grease seal will

accept grease pressure without damage, and is de-

signed to have grease pumped out through it during

lubrication. Even if grease leaks out around the top,

or bottom-plate gasket, continue pumping until new

grease is seen at the bushing seal opposite the

grease fitting; see

Fig. 4.

NOTE: For operation in very cold climates, use

NLGI Grade 1 (6% 12-hydroxy lithium stearate

grease).

33–02 Tie Rod Inspection

IMPORTANT: If the tie rod end boot is torn or

missing, replace the entire tie rod end. Do not

replace the boot only.

1. Shut off the engine, apply the brakes, and chock

the rear tires.

2. Check the tie rod boot for cracks, tears, or other

damage. If the tie rod boot is damaged, replace

the entire tie rod end.

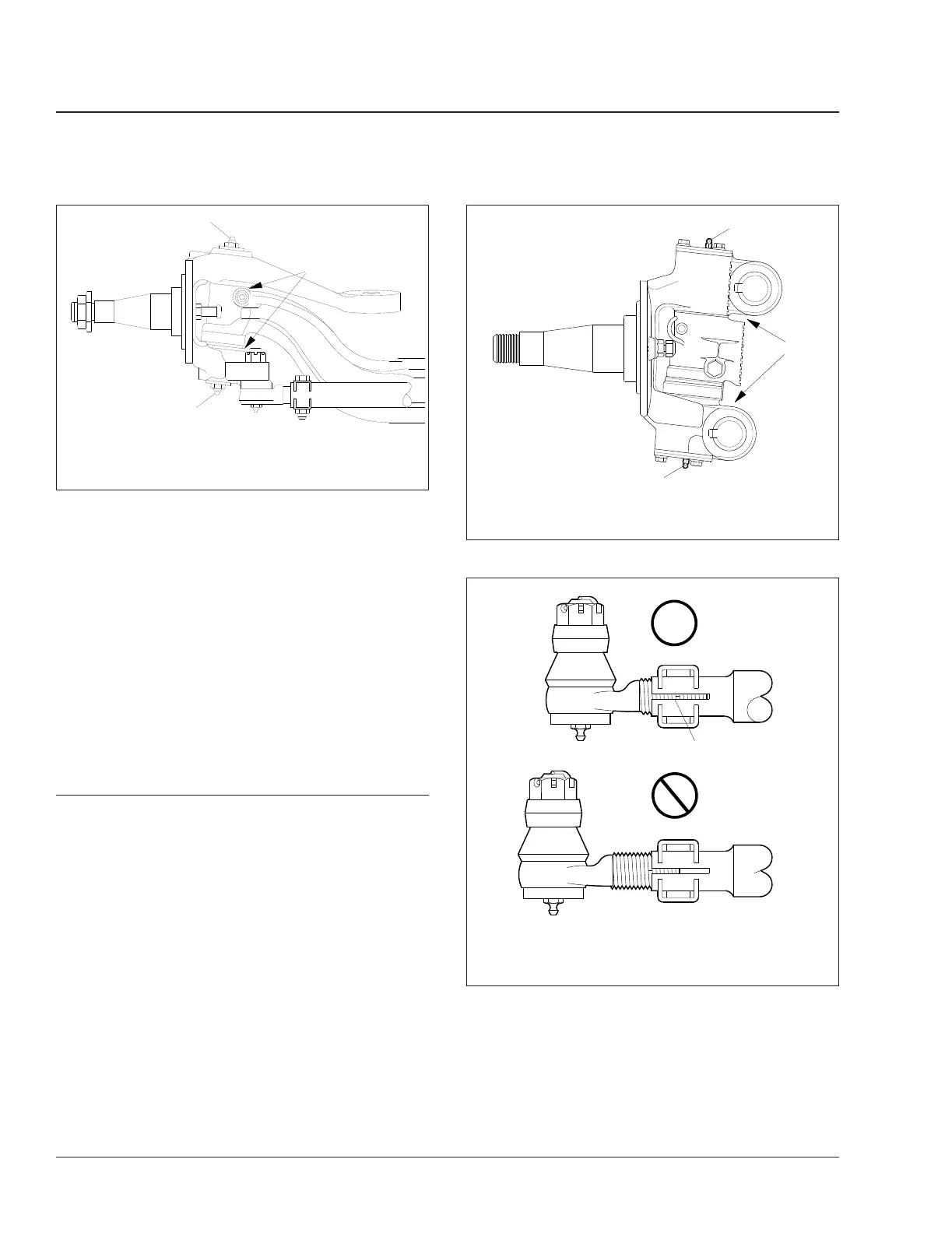

3. The threaded portion of the tie-rod end assembly

must be inserted all the way into the cross-tube

split for adequate clamping. See

Fig. 5. Replace

the components if this cannot be done. For in-

structions, refer to Group 33 of the 108SD and

114SD Workshop Manual.

4. Grasp by hand (or use a pipe wrench with jaw

protectors to avoid gouging the cross tube) and

slightly rotate the cross tube toward the front of

the vehicle and then slightly toward the rear.

11/21/95

f330129

1

1

A

A. Grease exits

1. Grease Fitting

Fig. 3, Dana Spicer Knuckle Pin Lubrication

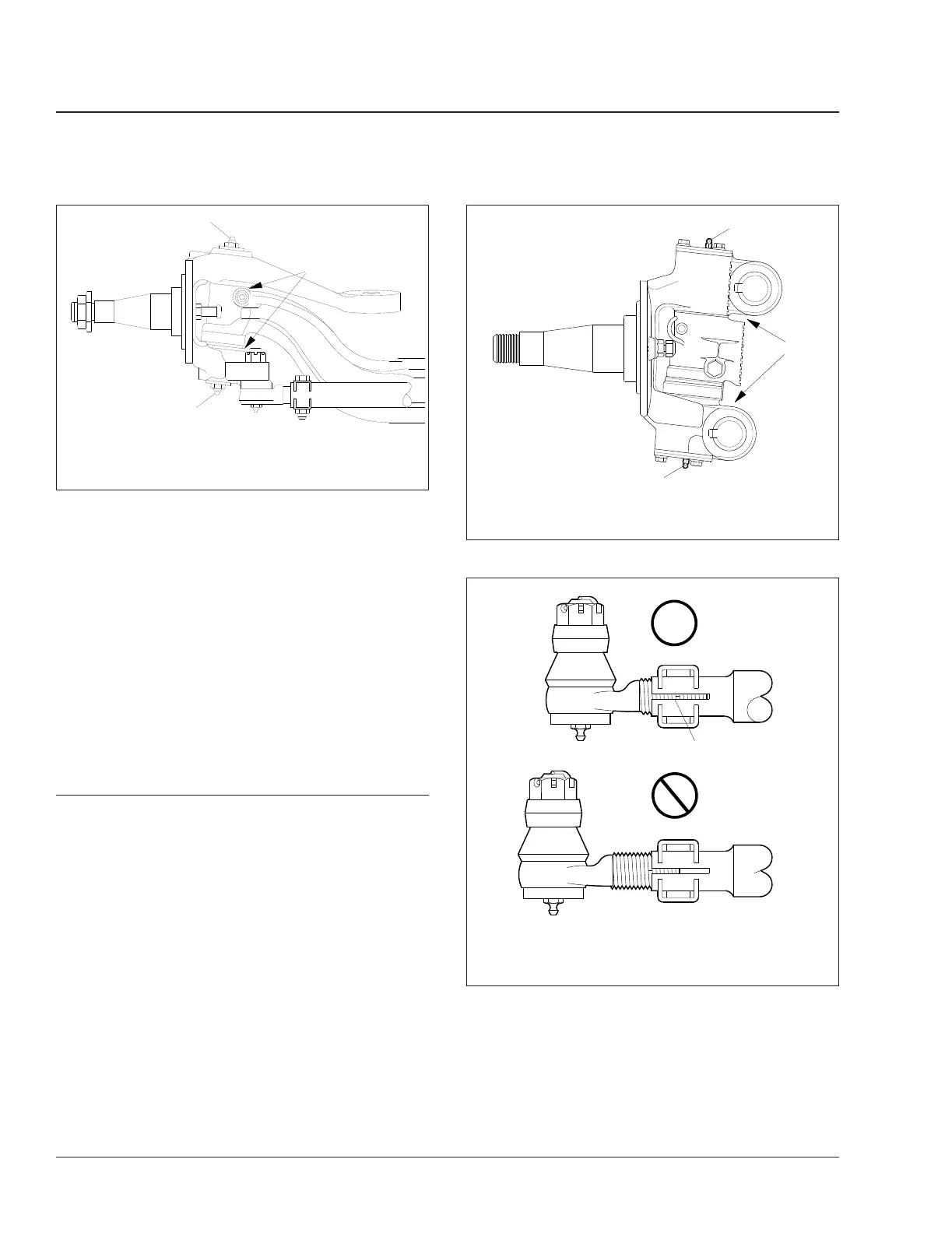

09/06/96 f320032a

A

1

1

A. Grease Exits

1. Grease Fitting

Fig. 4, Knuckle Pin Lubrication, Meritor Axles

f320033a

1

OK

OK

02/27/2007

NOTE: Shown without pinch bolt to provide clarity.

1. Cross-Tube Split

Fig. 5, Tie-Rod End Adjustment

Front Axle33

108SD and 114SD Maintenance Manual, May 201733/2

Loading...

Loading...