Dana Spicer and Haldex

CAUTION

Do not use moly-disulfide-loaded grease or oil.

Both the life and reliability of the slack adjuster

will be reduced if this type of grease is used.

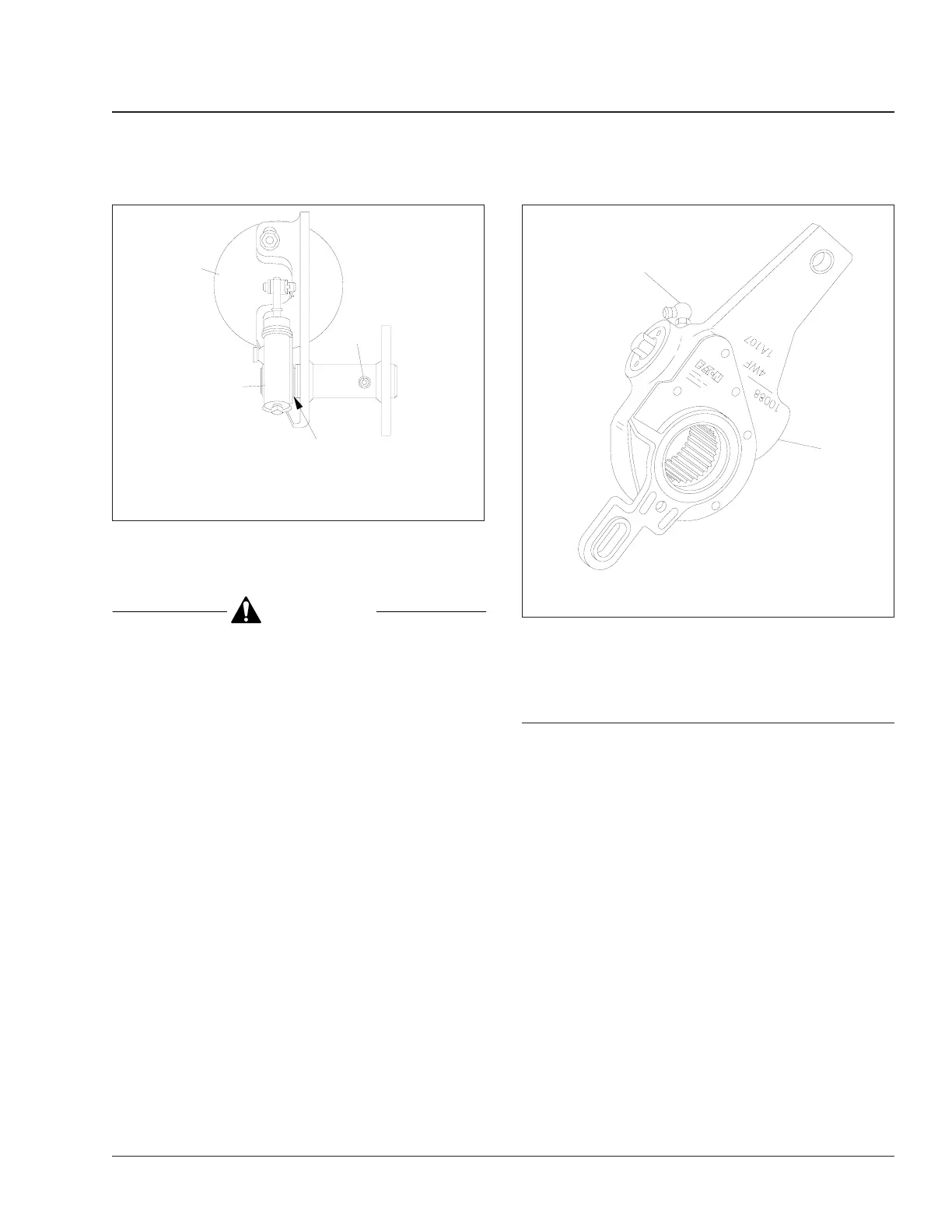

Lubricate the automatic slack adjuster at the grease

fitting (see Fig. 5). Use standard chassis lubricant.

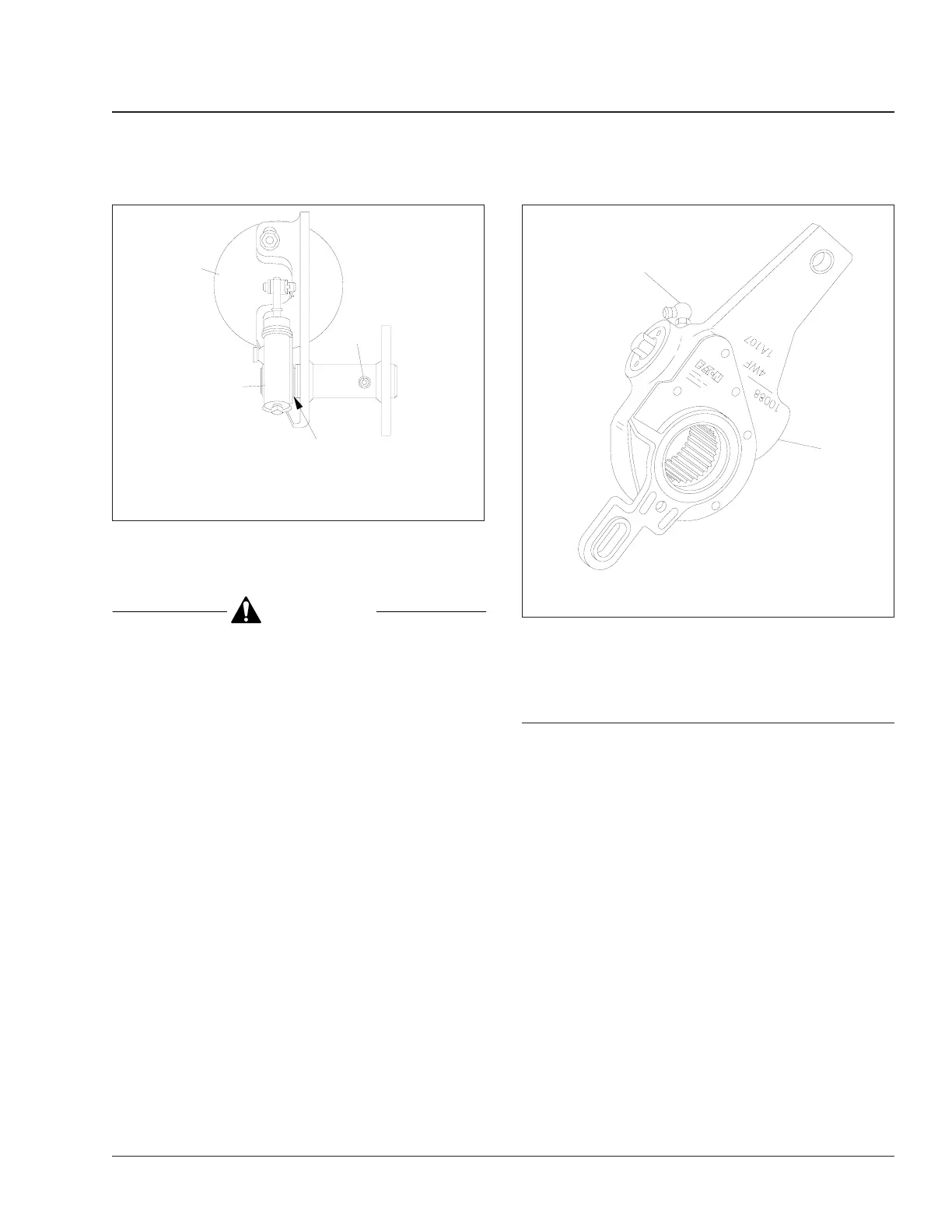

Gunite

For operating temperatures of –20°F (–29°C) and

higher, use Texaco Multifak EP-2 or Mobil Grease

No. 77.

For operating temperatures between –20°F (–29°C)

and –40°F (–40°C), use Lubriplate Aero grease.

Lubricate a Gunite automatic slack adjuster at the

grease fitting (see Fig. 6) until grease appears on

the camshaft, or flows from the grease-relief.

The newest Gunite automatic slack adjusters are

produced without a grease-relief. During lubrication

with a grease gun, lubricant is forced through the

drilled worm wheel onto the camshaft. Lubricate the

automatic slack adjuster at the grease fitting (see

Fig. 6) until grease appears on the camshaft.

42–07 Meritor Camshaft

Bracket Lubrication

IMPORTANT: Perform MOP 42–11 before lubri-

cating the camshaft bracket.

NOTE: If equipped with an extended-

maintenance Q Plus

™

brake system, the cam-

shaft bracket will not have a grease fitting.

These camshafts use a special NLGI grade syn-

thetic polyurea grease and do not require lubri-

cation for 3 years or 500,000 miles (800 000

km), whichever comes first. The extended-

maintenance camshaft bushings are lubricated

during the brake reline service interval. For ser-

vice and lubrication instructions, see Group 42

of the

Century Class Trucks Workshop Manual

.

For camshaft brackets with grease fittings, use an

NLGI Grade 1 or Grade 2 multipurpose chassis

grease.

f420011a

05/28/93

1

2

3

A

A. Grease Exit

1. Brake Chamber

2. Slack Adjuster

3. Non-Pressure-Relief

Grease Fitting

Fig. 4, Camshaft Bracket Lubrication

09/17/97

1

2

f421649

1. Grease Fitting 2. Slack Adjuster

Fig. 5, Dana Spicer and Haldex Automatic Slack

Adjuster

Brakes 42

Century Class Trucks Maintenance Manual, April 2005 42/5

Loading...

Loading...