83–01 Air Conditioner

Inspection

WARNING

Wear eye protection, gloves, and protective cloth-

ing when working on the air conditioning system.

Leaking refrigerant from a damaged hose or line

could cause blindness or serious skin burns.

Preliminary Checks

1. Park the vehicle on a level surface, apply the

parking brakes, and chock the tires.

2. Check the appearance of the refrigerant com-

pressor pulley assembly. If the friction surface of

the pulley shows signs of excessive grooving

due to belt slippage, replace both the pulley and

the drive plate. Inspect the refrigerant compres-

sor drive belt for damage, and check that the belt

is set at the proper tension. Also check the tight-

ness of the compressor mounting fasteners. For

instructions and torque values, see Group 01 of

the

Century Class Trucks Workshop Manual

.

3. Inspect the drive plate. If the friction surface of

the drive plate shows visible signs of damage

due to excessive heat, replace the drive plate

and pulley assembly. For instructions, see Group

83 of the

Century Class Trucks Workshop

Manual

.

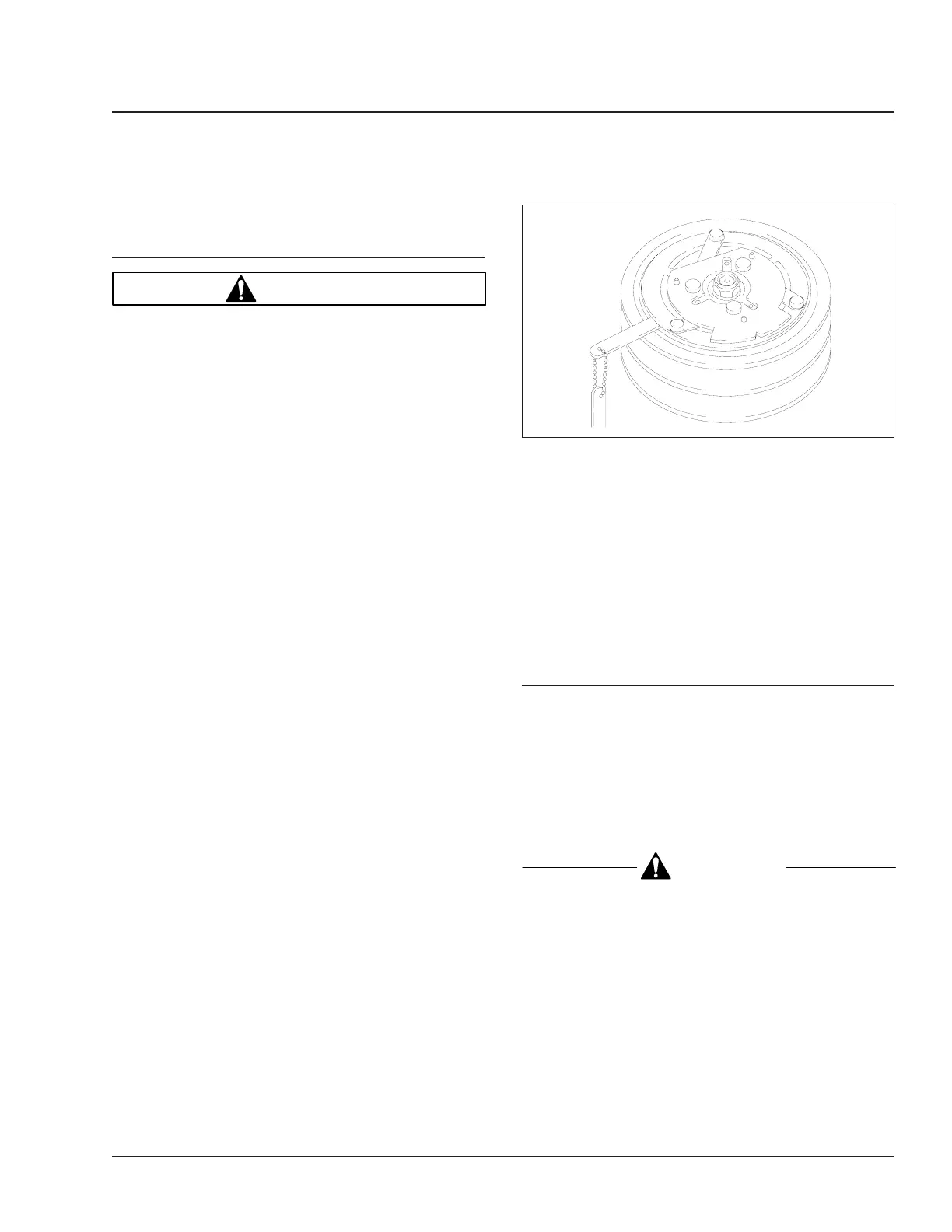

4. On a Sanden refrigerant compressor, use a

feeler gauge to check that the drive plate clutch

clearance is 0.016 to 0.031 inch (0.40 to 0.78

mm). See Fig. 1. If the drive plate clutch requires

adjustment, see Section 83.01, Subject 140 of

the

Century Class Trucks Workshop Manual

.

On a Climate Control refrigerant compressor,

place a feeler gauge between the air conditioner

compressor clutch and the pulley to check the

compressor clutch clearance. Drive plate to pul-

ley clearance should be 0.020 to 0.030 inch

(0.50 to 0.76 mm). If the clearance is 0.035 inch

(0.89 mm) or greater, replace the clutch. For in-

structions, see Section 83.00, Subject 140 of

the

Century Class Trucks Workshop Manual

.

5. Inspect the compressor clutch coil wire. Check

that the connector is not damaged or loose. Re-

place the wire if it is damaged.

6. Check the overall condition of the air conditioning

hoses. Look for cracks, cuts, and abrasions on

the hoses. Replace damaged hoses. Check for

loose fittings on all of the air conditioning compo-

nents.

7. Check for road debris buildup on the condenser

fins. Using air pressure and a whisk broom or a

soapy spray of water, carefully clean off the con-

denser. Be careful not to bend the fins.

83–02 Air Filter Replacement

Cab Fresh Air Filter

Replacement, Water-Valve

Controlled

The cab fresh air filter must be replaced every six

months, regardless of mileage, to permit proper op-

eration of the HVAC system.

CAUTION

If the fresh air filter is not replaced every six

months, damage to the heater and air conditioner

components could occur. The HVAC system

should not be operated without the fresh air filter

installed.

IMPORTANT: When replacing the air filter, use

only a Freightliner-approved air filter.

1. Park the vehicle on a level surface. Apply the

parking brakes and chock the rear tires.

08/25/94

f830641

Fig. 1, Drive Plate Clearance Inspection

Heater and Air Conditioner 83

Century Class Trucks Maintenance Manual, April 2003 83/1

Loading...

Loading...