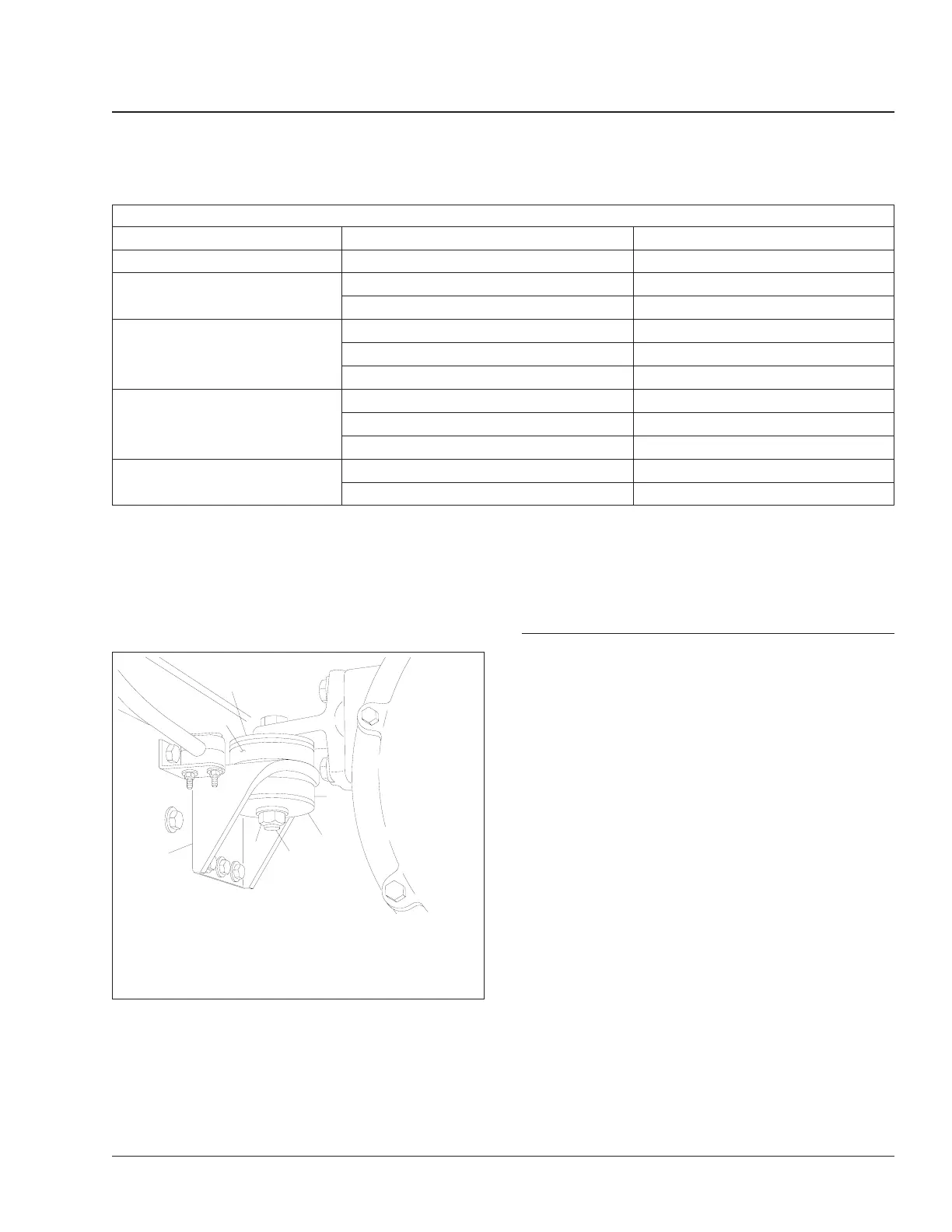

Drive Belt Tension

Engine Component Belt Tension: lbf (kg)

Caterpillar C10 (3176) Refrigerant Compressor 80 to 100 (36 to 45)

Caterpillar 3406E

Alternator and Refrigerant Compressor 40 to 50 (18 to 23), per belt

Fan 80 to 100 (36 to 45)

Cummins M11

Alternator 90 to 120 (41 to 55)

Fan 155 to 165 (70 to 75)

Refrigerant Compressor 80 to 100 (36 to 45)

Cummins N14

Alternator 40 to 50 (18 to 23), per belt

Fan 80 to 120 (36 to 55)

Refrigerant Compressor 80 to 100 (36 to 45)

Detroit Diesel Series 60

Alternator and Refrigerant Compressor 80 to 100 (36 to 45), Power Band

Fan 60 to 80 (27 to 36)

Table 1, Drive Belt Tension

Periodically inspect the rubber isolators for cracks,

cuts, wear, or damage, and replace them if neces-

sary. See Group 01 of the

Century Class Trucks

Workshop Manual

for isolator replacement

procedures.

01–04 Engine-Support

Fasteners Check (Noise

Emission Control)

Front and rear engine supports for vehicles built from

January 7007 require no periodic maintenance.

Mounts should be inspected when the engine is re-

moved for service. For vehicles manufactured prior to

January 2007, perform the following check.

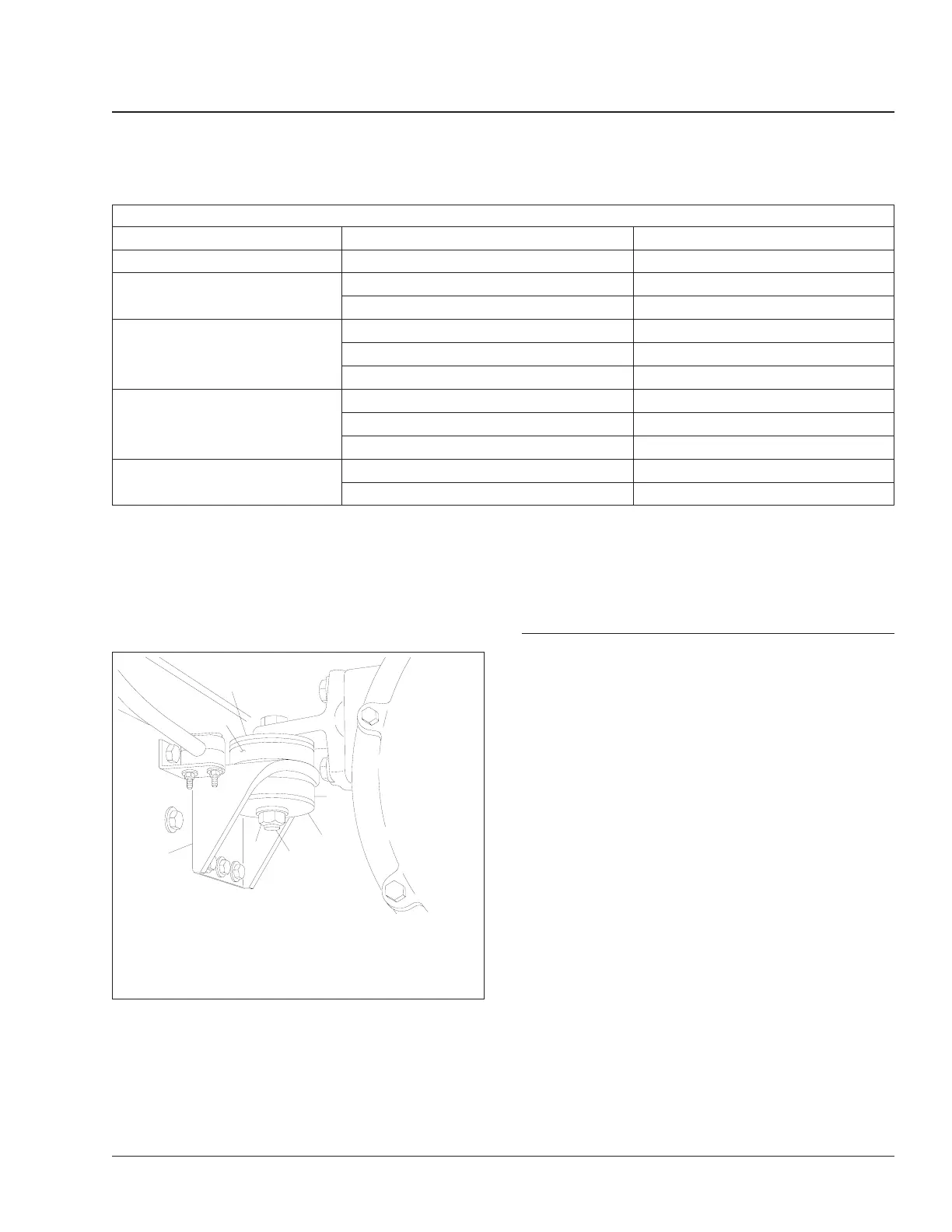

Check the rear engine-support fasteners (see Fig. 3,

Ref. 4) for tightness. Tighten the 3/4-inch fasteners

215 to 265 lbf·ft (292 to 359 N·m).

Check the front engine-support fasteners for tight-

ness. Tighten the 5/8-inch fasteners 125 lbf·ft (170

N·m).

NOTE: At engine overhaul, and whenever the

engine has been removed, inspect the lower

and upper isolators (see Fig. 3, Refs. 1 and 6),

and replace them if they are worn; this applies

to both the front and rear isolators. See Group

01 of the

Century Class Trucks Workshop

Manual

for procedures.

f220047a

1

2

3

4

5

6

2

10/05/94

1. Lower Isolator

2. Engine-Support

Washer

3. 3/4–10 Capscrew

4. 3/4–10 Hexnut

5. Engine Mount

6. Upper Isolator

Fig. 3, Rear Engine Mount Isolators and Fasteners

Engine 01

Century Class Trucks Maintenance Manual, January 2007 01/3

Loading...

Loading...